A kind of encapsulation thin film and its preparation method, optoelectronic device

A technology for encapsulating film and device surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

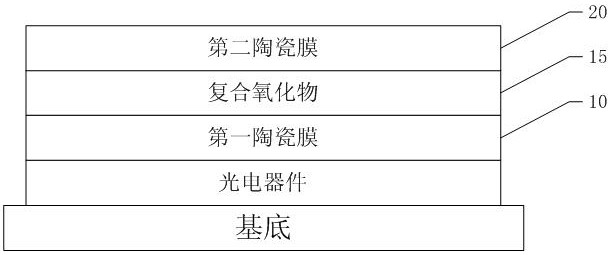

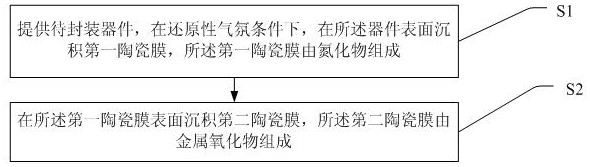

[0037] Further, the present invention also provides a method for preparing an encapsulation film, wherein, such as figure 2 shown, including steps:

[0038] S1. Provide a device to be packaged, and deposit a first ceramic film on the surface of the device under a reducing atmosphere condition, and the first ceramic film is composed of nitride;

[0039] S2. Depositing a second ceramic film on the surface of the first ceramic film, where the second ceramic film is composed of metal oxide.

[0040] In one embodiment, the first ceramic film is prepared on the surface of the device by magnetron sputtering, and a certain amount of reducing atmosphere is introduced during the process of preparing the first ceramic film, and the reducing atmosphere is hydrogen or carbon dioxide.

[0041] Preferably, the flow rate of the reducing atmosphere is 5-10 sccm.

[0042] Preferably, during the preparation of the first ceramic film, the sputtering power is 50-80W; and / or the sputtering pres...

Embodiment 1

[0051] 1. The structure of the optoelectronic device is: ITO substrate / PEDOT:PSS (50 nm) / poly-TPD (30 nm) / quantum dot light-emitting layer (20 nm) / ZnO (30nm) / silver (70 nm) / encapsulation layer (550nm). Wherein, the material of the packaging film is AlN film / Y 2 o 3 film, the thickness of the AlN film is 500 nm, Y 2 o 3 The film thickness is 50 nm, and both are prepared by RF radio frequency sputtering method.

[0052] 2. The packaging method of the optoelectronic device comprises steps:

[0053] 1) On the top surface of the QLED silver electrode, the AlN target is sputtered into a film by radio frequency sputtering. The sputtering process is: power 60 W, sputtering pressure 0.6 Pa, argon gas flow rate 50 sccm, hydrogen gas The flow rate is 5 sccm, the sputtering time is 25min, and the thickness is about 500 nm;

[0054] 2), the method of radio frequency sputtering is also used to prepare Y 2 o 3 Thin film, the sputtering process is as follows: power 40 W, sputtering pr...

Embodiment 2

[0056] 1. The structure of the optoelectronic device is ITO substrate / PEDOT:PSS (50 nm) / poly-TPD (30 nm) / quantum dot light-emitting layer (20 nm) / ZnO (30nm) / silver (70 nm) / encapsulation layer ( 1100nm). Wherein, the material of the packaging film is AlN film / MgO film, the thickness of the AlN film is 1000 nm, and the thickness of the MgO film is 100 nm, both of which are prepared by RF radio frequency sputtering method.

[0057] 2. The packaging method of the optoelectronic device comprises steps:

[0058] 1) On the top surface of the silver electrode of the QLED, the AlN target is sputtered into a film by radio frequency sputtering. The sputtering process is: power 80 W, sputtering pressure 0.8 Pa, argon gas flow rate 50 sccm, hydrogen gas The flow rate is 5 sccm, the sputtering time is 50min, and the thickness is about 1000 nm;

[0059] 2) The MgO film was also prepared by RF sputtering. The sputtering process was as follows: power 40 W, sputtering pressure 0.5 Pa, argon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com