Screening panel

A screening plate and screening technology, applied in the directions of grading, sieving, solid separation, etc., can solve the problems of expensive hard chrome treatment, shortened plate life, high wear area, etc., to increase the available opening area and improve productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

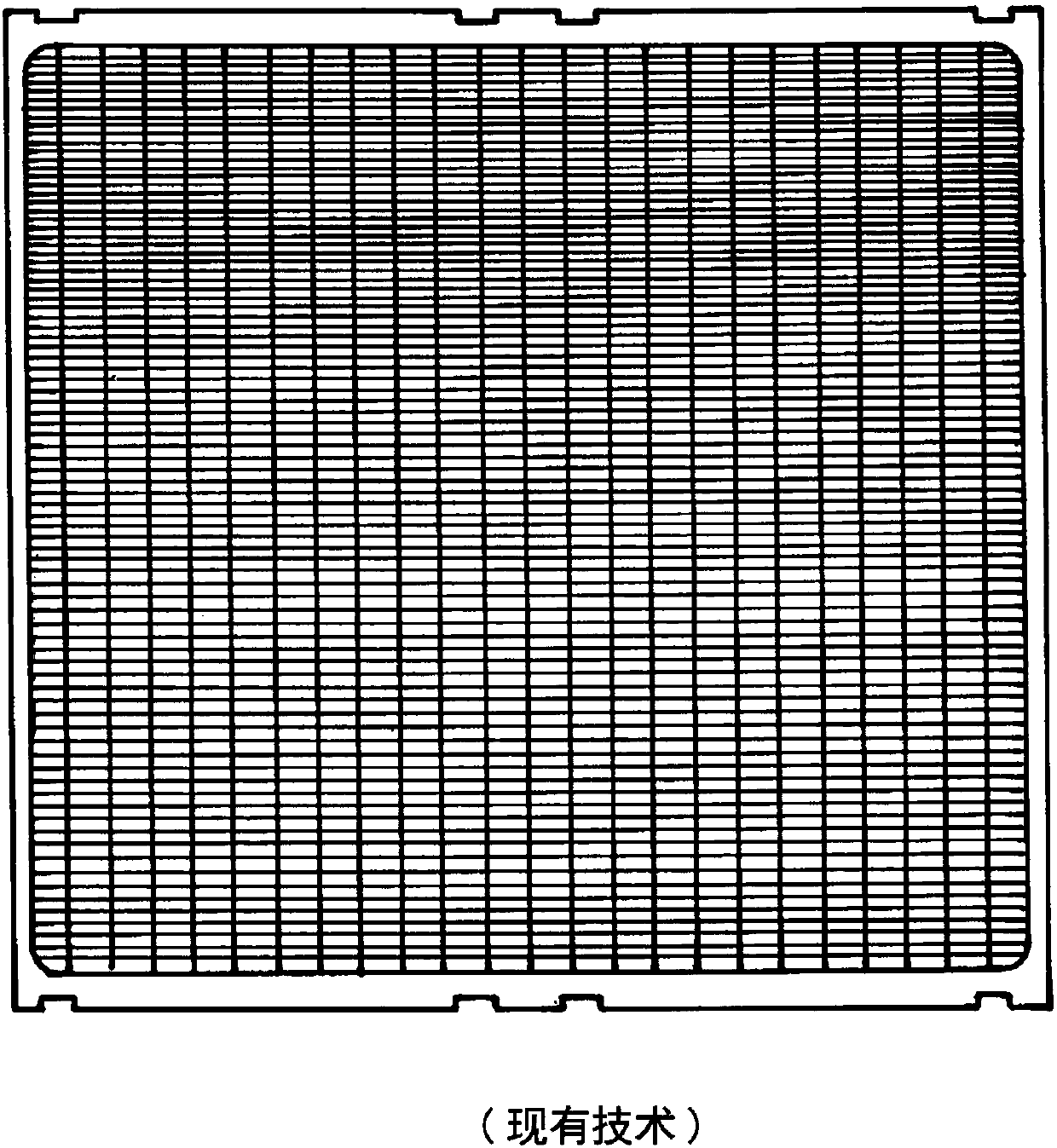

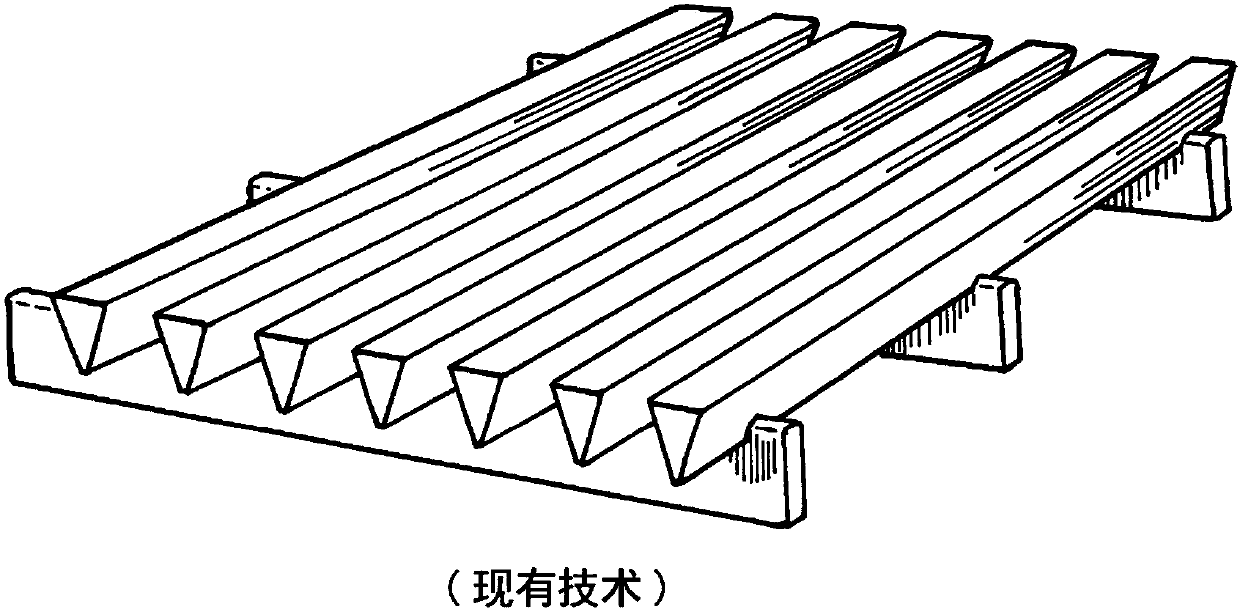

[0017] like figure 1 and figure 2 As shown, a conventional wedge wire plate consists of a screening surface of a stainless steel flat top wedge welded to an underlying support bar. The screen openings are defined by the spaces between the upper ends of the flat-topped wedges. The screening panels are surrounded by a polyurethane frame incorporating the desired fixing system around the perimeter of the screening surface.

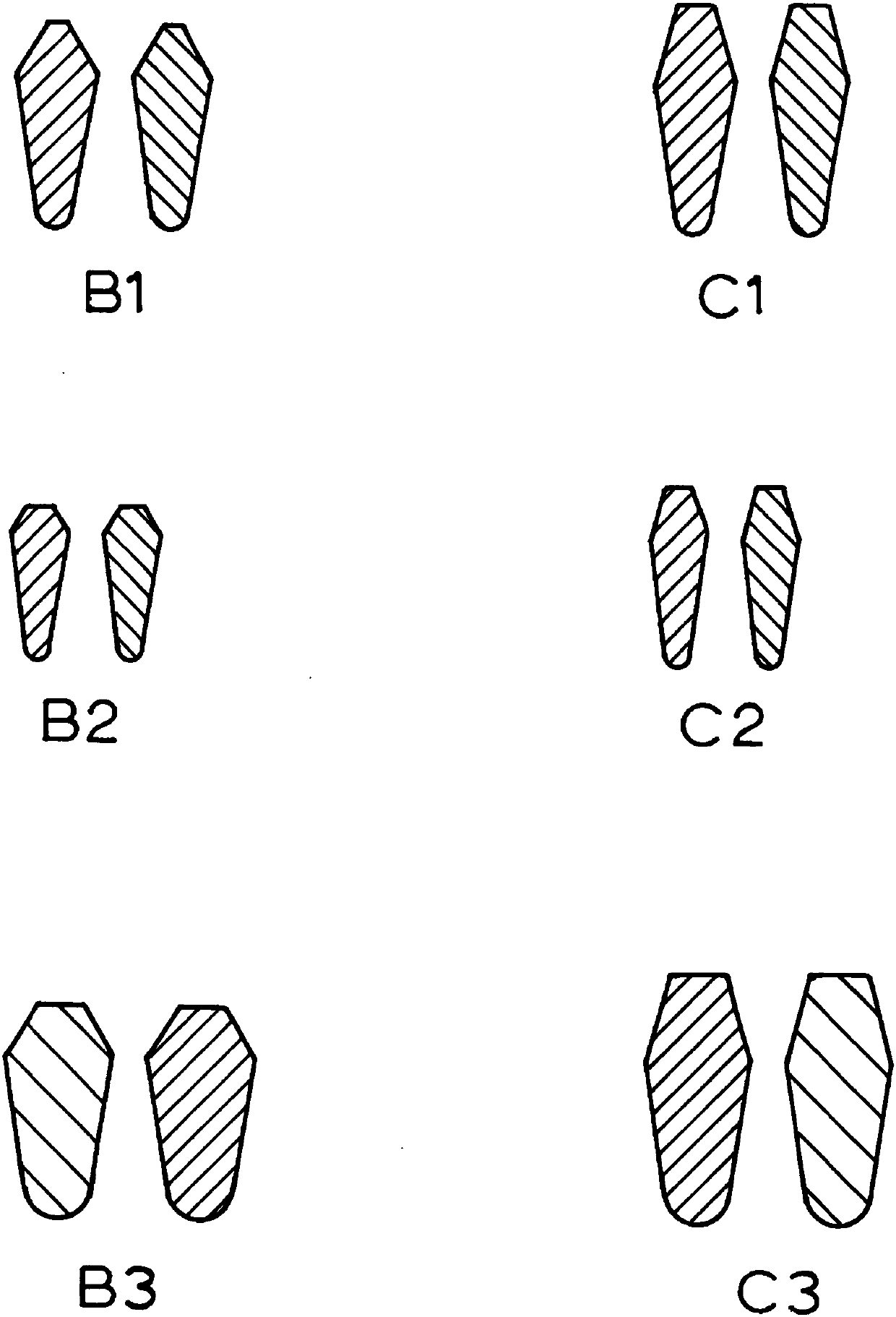

[0018] An improvement of the present invention is to provide a truncated diamond wire profile, and examples of these truncated diamond wire profiles are shown in image 3 .

[0019] To manufacture the plate, the first step is to form the wire cross-sectional profile. Stainless steel wire is usually round and wound onto a drum, and in order to form the desired cross-section, the wire needs to be cold drawn (drawn) through a die that is usually formed on the surface of two mating wheels and has The shape or contour in the circumference of a wheel.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com