Method for manufacturing rolling bearing lubricated by maintaining lubricating oil through UHMWPE (Ultra High Molecular Weight Polyethylene) and rolling bearing

A technology for rolling bearings and manufacturing methods, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as resistance to vibration and shock, difficulty in achieving lifetime lubrication, grease leakage, etc., achieve long anti-wear life, and realize maintenance-free The effect of lifetime lubrication and sufficient oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Microporous oil-containing UHMWPE is cured on the holder

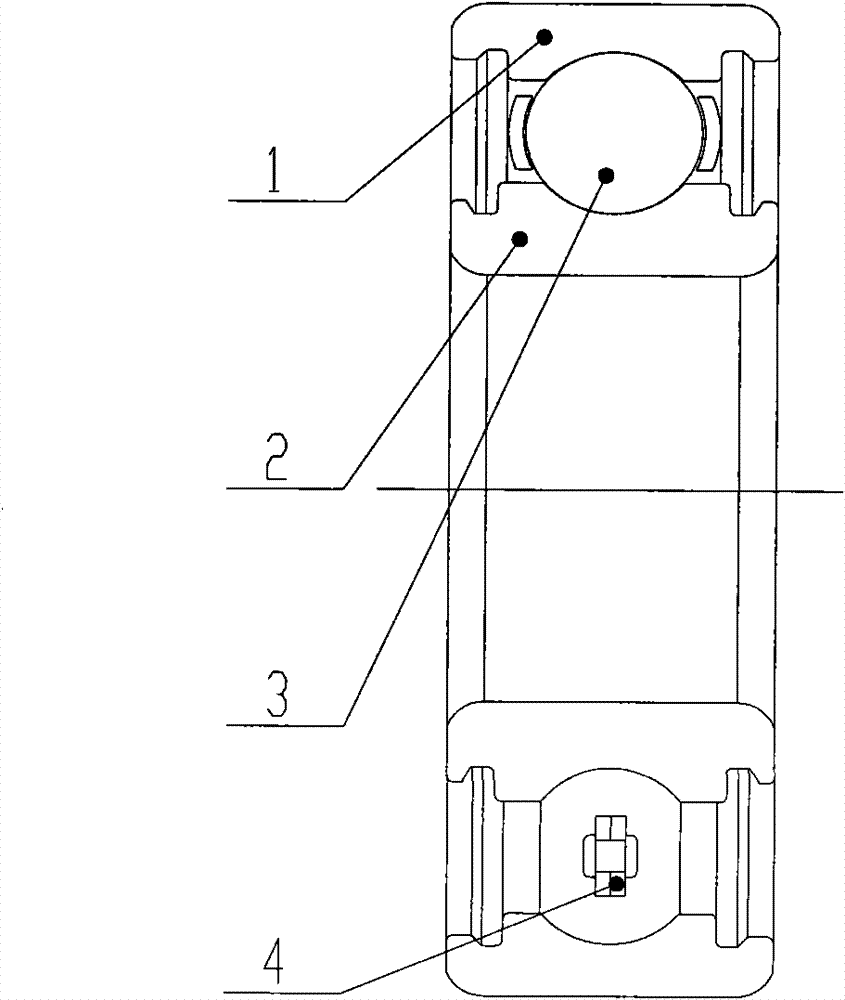

[0033] First of all, provide the normal rolling bearings assembled with fittings, cleaned and dried, including outer ring 1, inner ring 2, bearing rolling elements 3 and cage 4, such as figure 1 .

[0034] Next, provide a semi-fluid mixture comprising at least UHMWPE and lubricating oil, the molecular weight of UHMWPE is 1 million to 10 million, and its molecular formula is (CH 2 -CH 2 ) n or (C 2 h 4 ) n , The lubricating oil can be mineral oil, semi-synthetic oil, fully synthetic oil, various functional additives can be added in the lubricating oil.

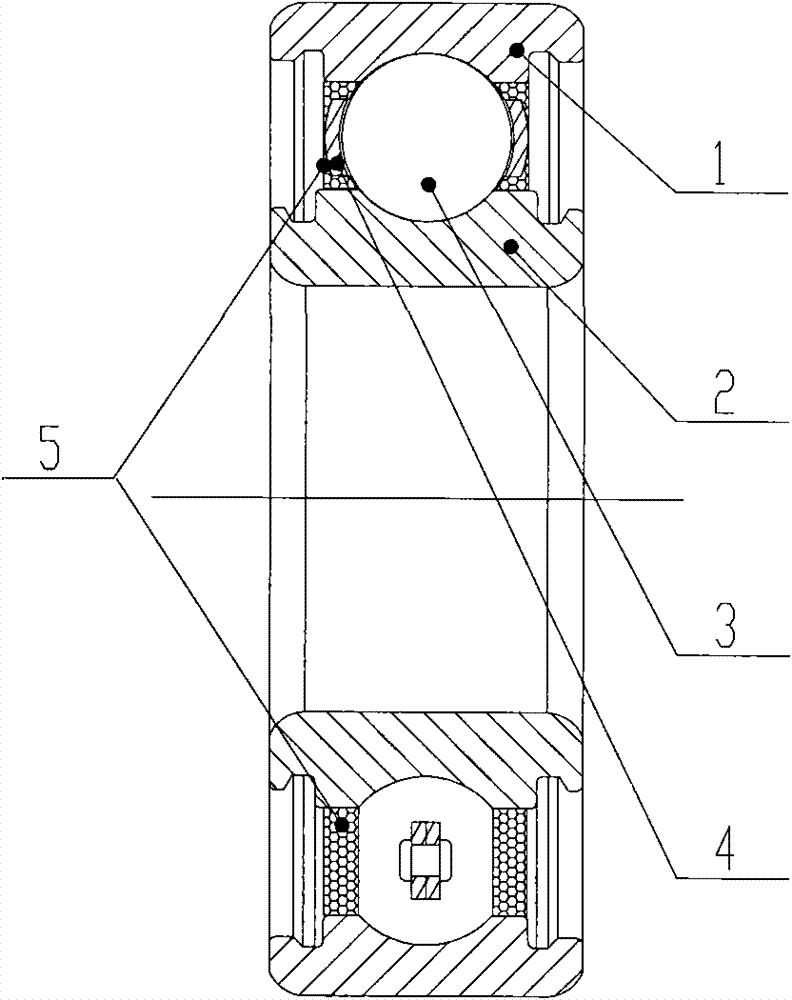

[0035] Inject the semi-fluid mixture into the figure 1In the inner cavity of the rolling bearing shown, the injection amount is selected to be 100% of the free space inside the bearing, and it is mainly covered on the cage 4, and the rolling bearing is heated after the semi-fluid mixture is injected, and the heating temperature is higher than the gel po...

Embodiment 2

[0040] 2. Using microporous oil-containing UHMWPE to lubricate rolling elements

[0041] A method for manufacturing a rolling bearing maintained and lubricated by UHMWPE, characterized in that it comprises the following steps:

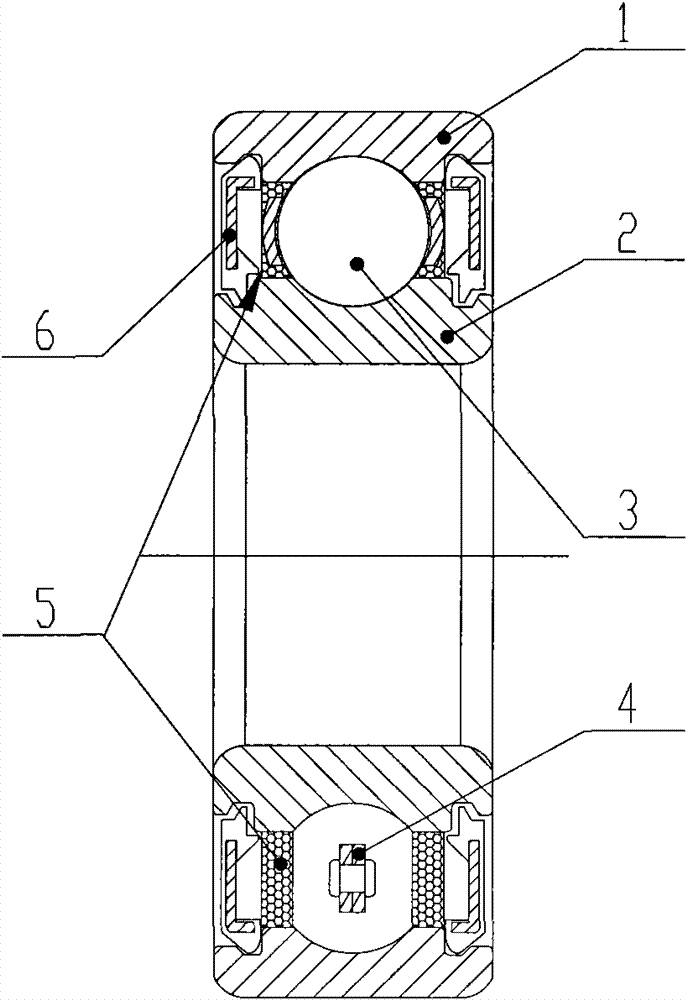

[0042] First, make a lubricating rolling body. The specific steps are: making a mixture containing at least UHMWPE and lubricating oil. The mixture is semi-fluid at room temperature. The molecular weight of UHMWPE is 1 million to 10 million. The lubricating oil can be mineral Oils, semi-synthetic oils and fully synthetic oils, lubricating oils have a viscosity of 5 to 5000 centistokes (cst) at 40 degrees Celsius, UHMWPE and lubricating oils constitute 10% to 50% and 50% to 90% of the total weight of the mixture, respectively . Inject the semi-fluid mixture into a mold whose inner cavity is in the shape of the rolling element 3 of the bearing but with a slightly smaller diameter, heat it in a temperature range higher than the gel point of UHMWPE and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com