Clutch mechanism with plastic washers disposed between disc packs and reactors

A clutch mechanism, reaction technology, applied in the field of transmission systems, to achieve the effects of high dimensional stability, high wear resistance, high mechanical strength and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description and claims, the terms "front" or "rear" will be used in a non-limitative manner to aid in understanding the direction determined according to the determined axial orientation relative to the rotational axis O of the double wet clutch mechanism 1, And the terms "inward / inward" or "outward / outward" aid understanding with respect to the axis of rotation O and in terms of a radial orientation orthogonal to said axial orientation.

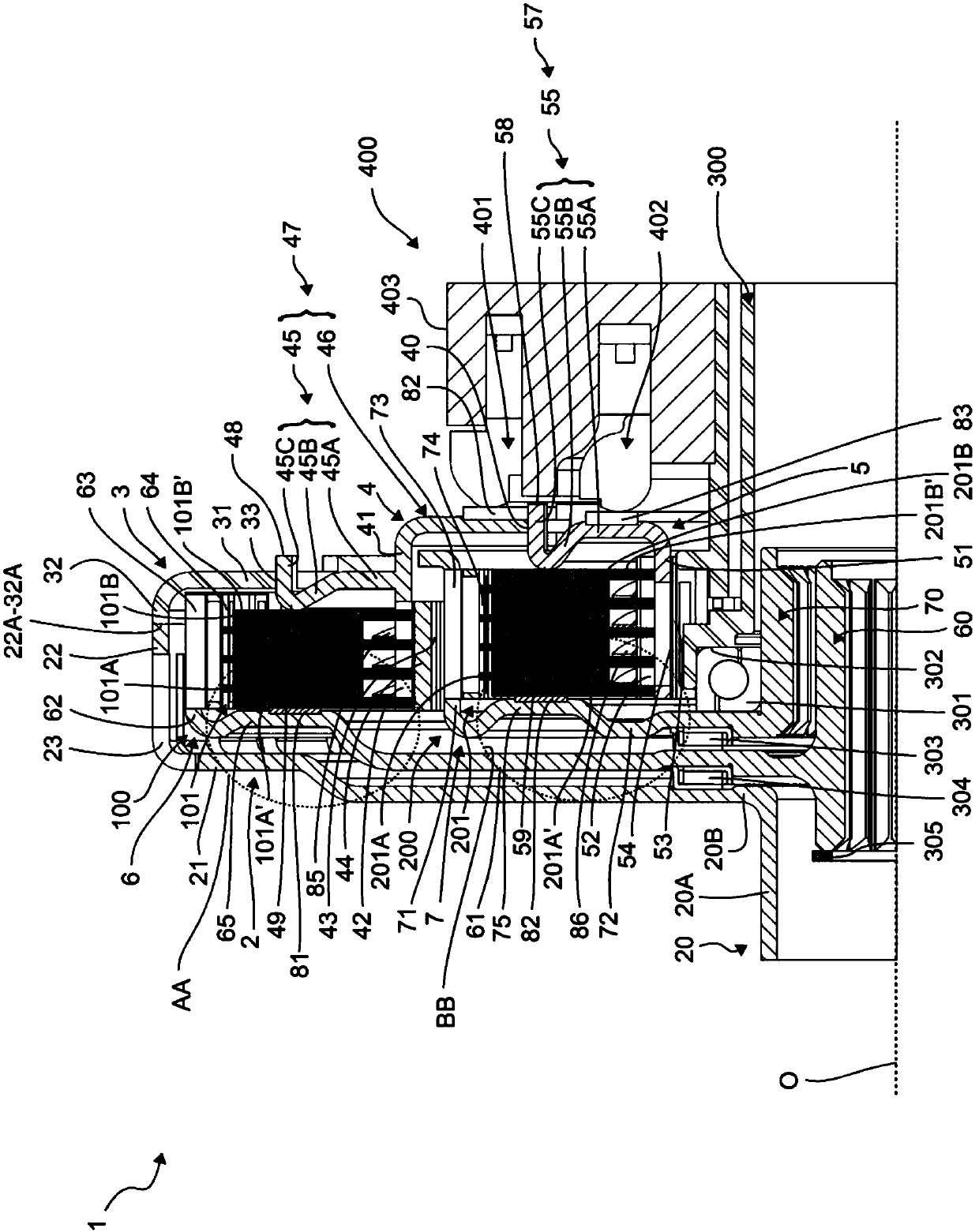

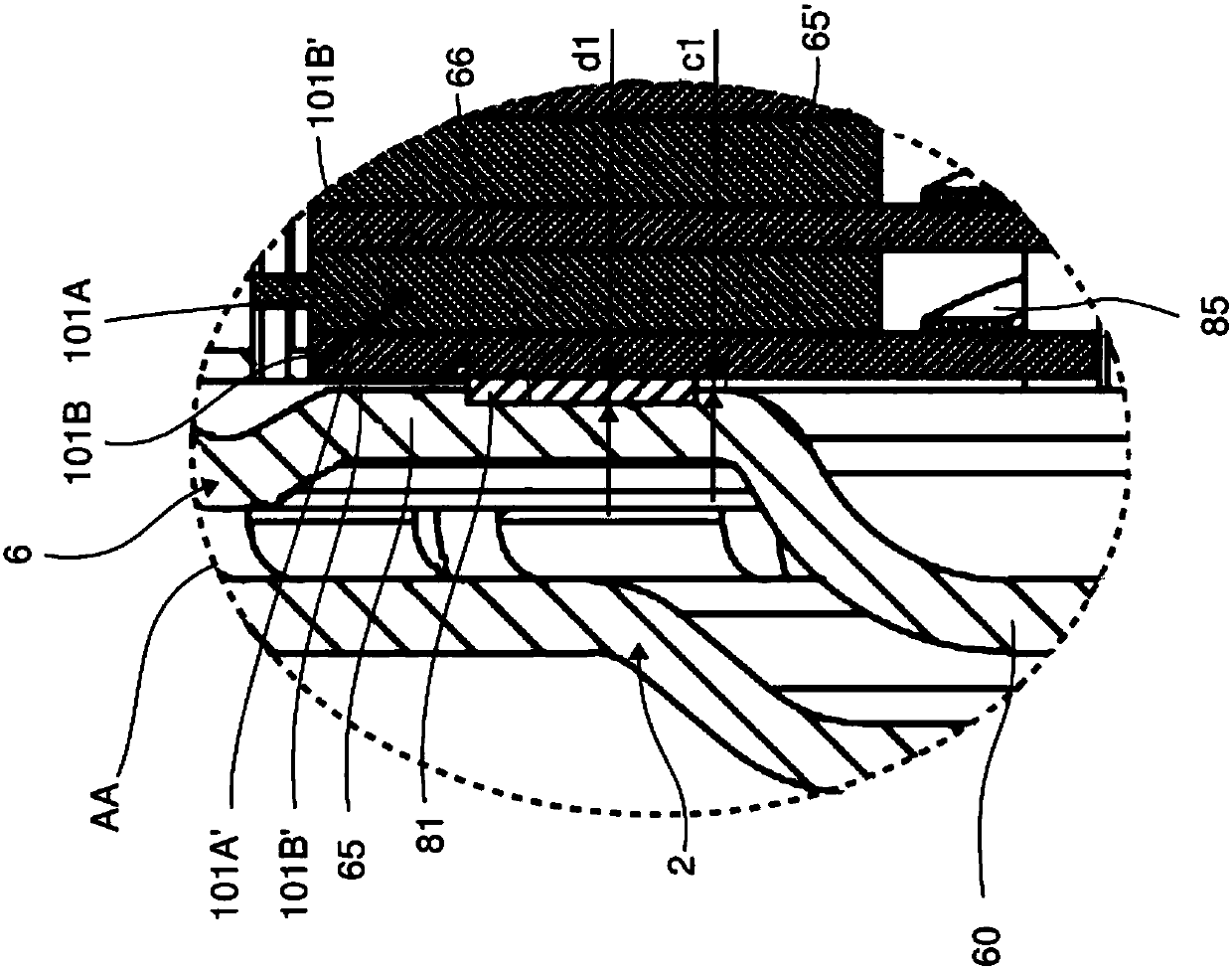

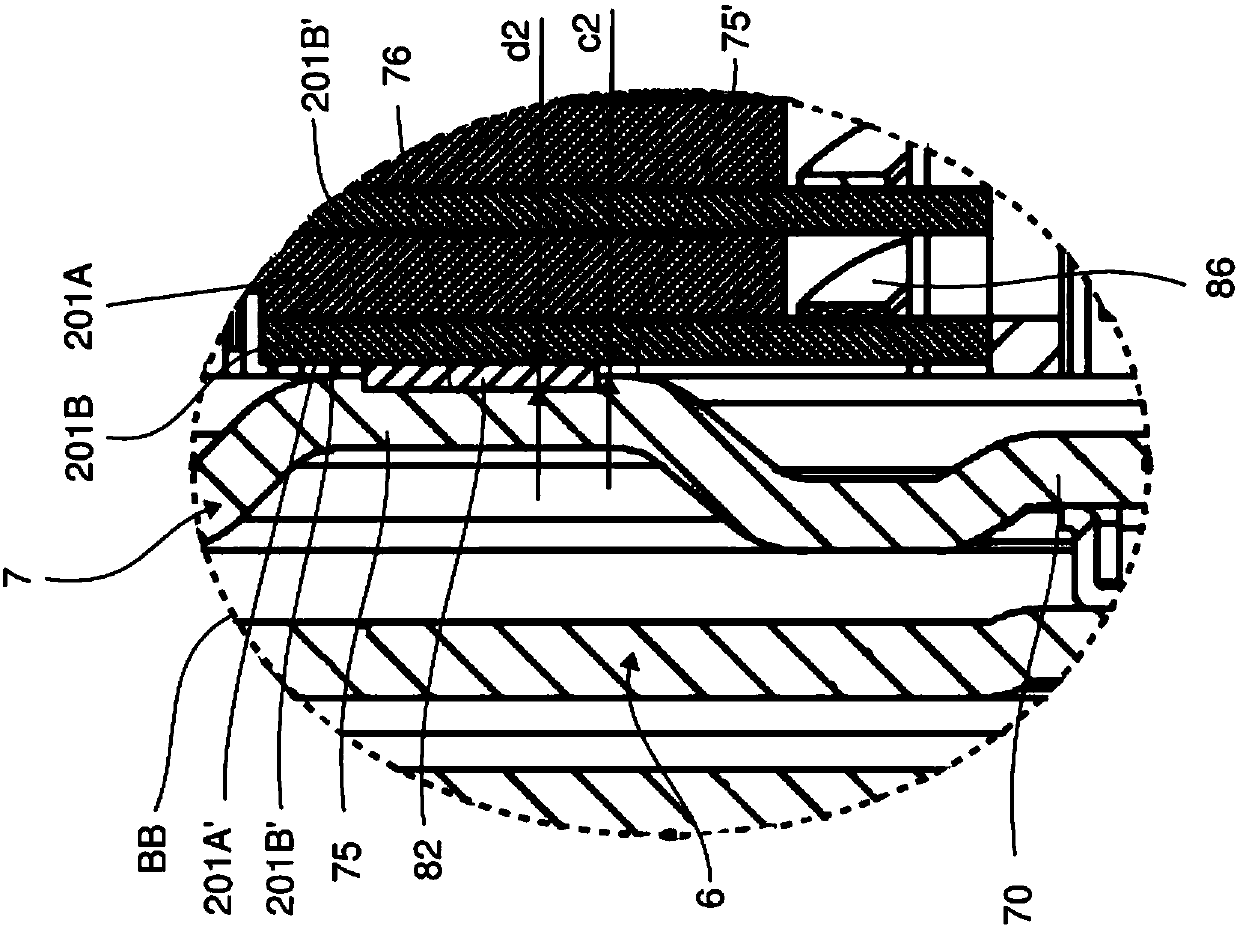

[0035] figure 1 A radial double wet clutch mechanism 1 for a transmission system (not shown) is shown, said clutch mechanism 1 , which has an axis of rotation O. Such transmission systems are designed to be installed in motor vehicles. The double wet clutch mechanism 1 has a transmission plate 2 connected to an input hub 20 and a blocking plate 3 fastened to the transmission plate 2 . The first inner disc carrier 4 and the second inner disc carrier 5 of the clutch mechanism 1 are partially shown. The blocking plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com