Square ridge type edge modular female and male formwork system

A formwork system, a square technology, is applied to formwork/formwork components, formwork/formwork/work frame connectors, construction components on-site preparation, etc. Corrosive decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

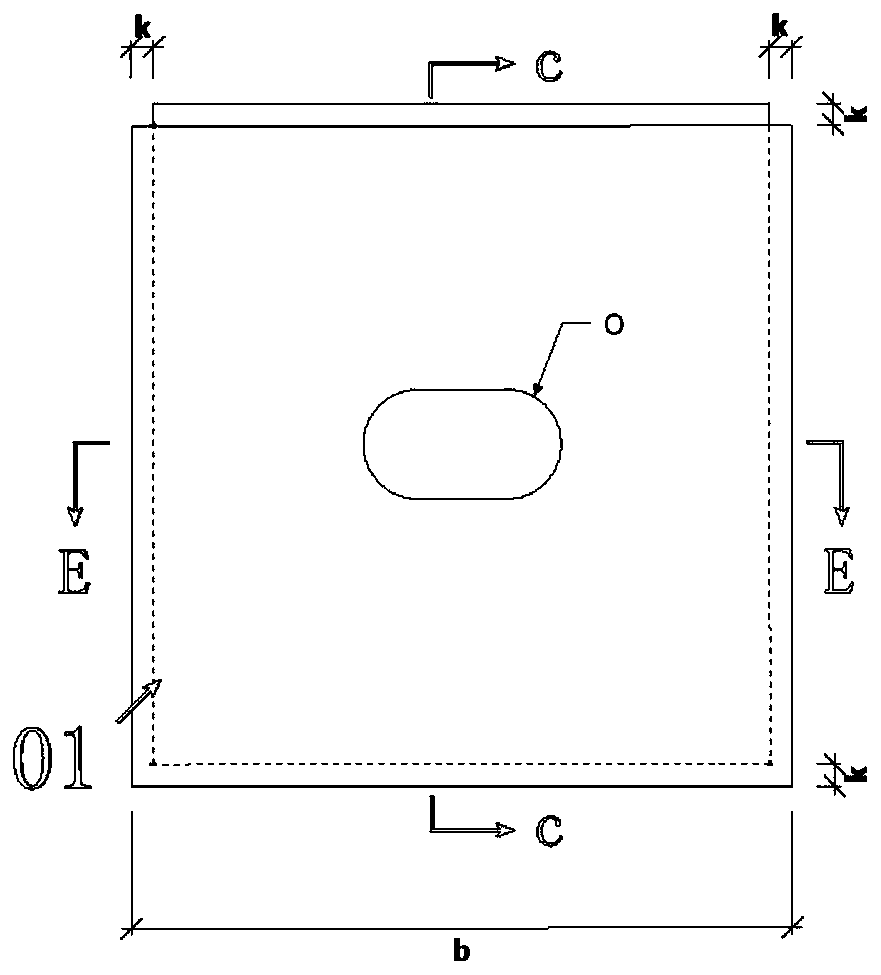

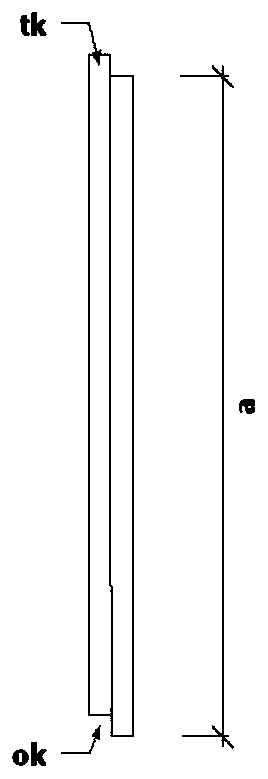

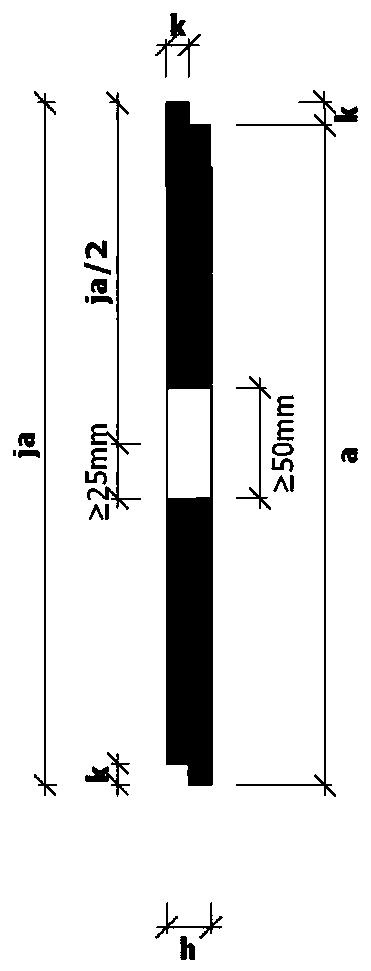

[0174] Embodiment 1. The modular yin and yang formwork system with square sill edge, as shown in Figure 1-15, consists of the following parts:

[0175] 1. The main part of the system: "Square sill-shaped edge modular yin-yang formwork" (abbreviation: "Shan-style formwork");

[0176] 2. Main accessories of the system: "Synthetic screw 09 with inner threaded sleeve at the top of the arc ring" (abbreviation: "Synthetic screw 09");

[0177] 3. Common accessories: "Eccentric selection threaded hole formwork cover" (abbreviation: "formwork cover");

[0178] 4. Other components: The steel pipes, fasteners, square bars, umbrella cards and other components in the original system are inherited and retained.

[0179] Note: The common accessories are the common accessories of the main parts of the system and the main parts of the system

[0180] System master

[0181] The main part of the system: the basic features of the "Canyon formwork" include:

[0182] 1. "Square sill edge" is a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com