Bearing for shed machine or motion transmission system, heald frame motion lever comprising such bearing, and shed machine comprising such lever or bearing

A motion transmission, bearing technology, applied in the field of weaving mechanism levers and shed forming machines, can solve the problems of cost and size of bearing components, aggravate the fatigue of rolling elements and track materials, move out of the load area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

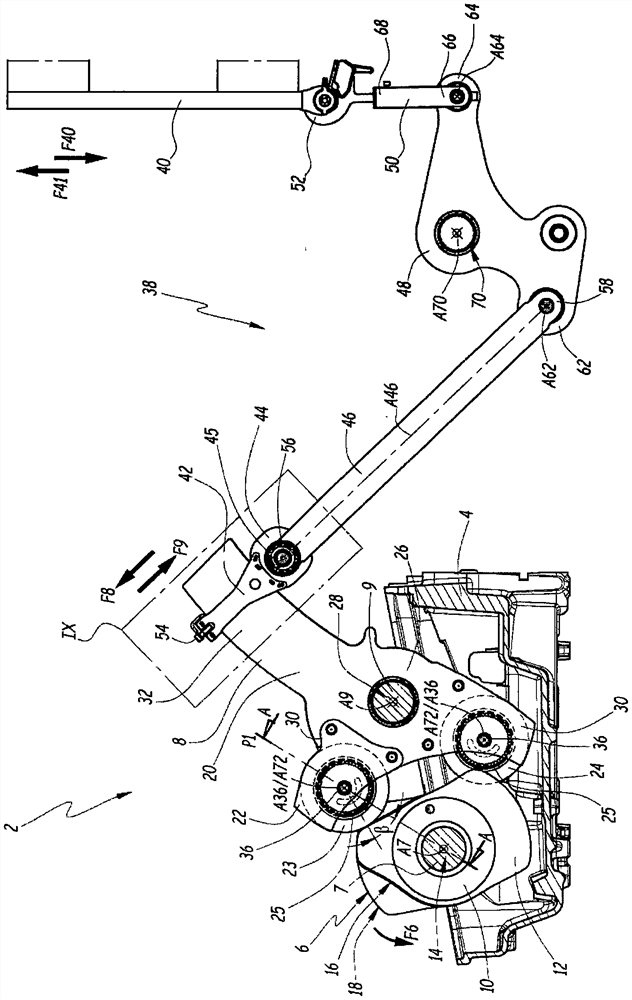

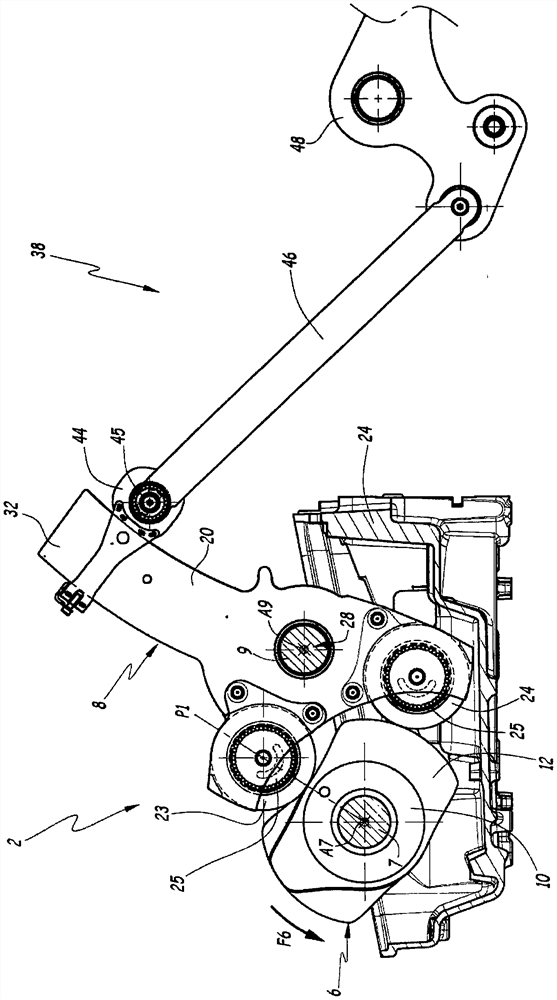

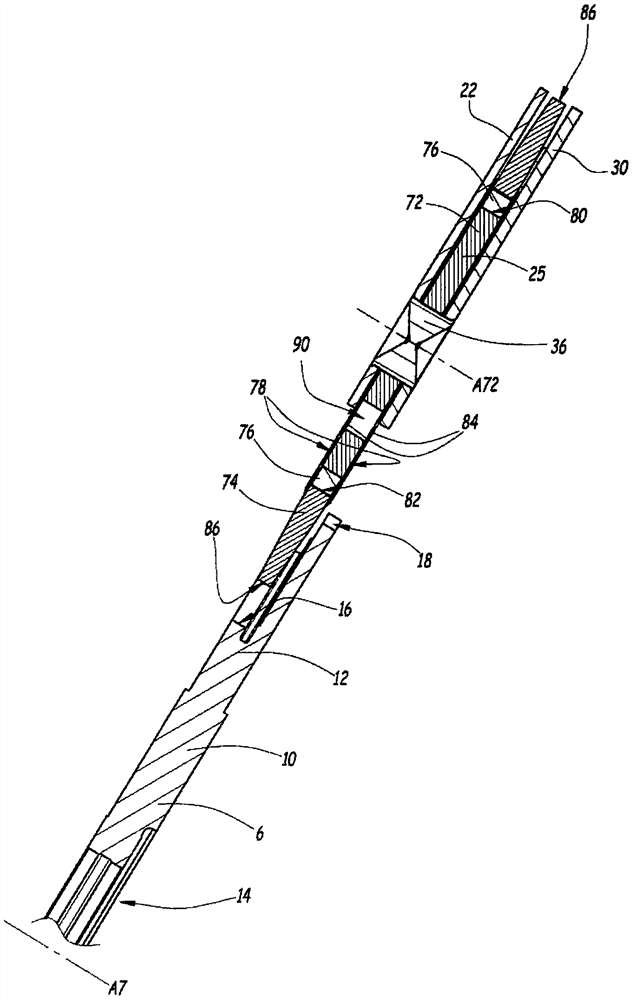

[0039]figure 1 The shuttle formation machine 2 is shown, and the shuttle forming machine 2 is schematically illustrated in order to facilitate understanding. This homosal forming machine 2 is a caminer.

[0040]The shuttle forming machine 2 includes a frame 4, a set of main cams 6, and a set of output lever 8. In fact, the plurality of main cams 6 are mounted on the common shaft 7 and are arranged in parallel along the longitudinal axis A7 of the common shaft 7. Similarly, the plurality of lever 8 are mounted on the common shaft 9 and are parallel along the longitudinal axis A9 of the common shaft 9. The frame 4 is fixed when the homographic machine 2 is used, and includes various essential members for placing other components of the hob forming machine and for driving the lever 8. The cover (not shown) is closed at the top, and the lever 8 is allowed to pass. In the rest of this specification, the cams 6 and lever 8 discussed arefigure 1 Those shown in it.

[0041]The cam 6 includes a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com