Integral type flat top plate structure of railway vehicle

A rail vehicle, integrated technology, applied in the direction of railway roof, railway car body parts, railway vehicle lighting devices, etc., can solve the problems of easy aging, performance degradation, strength and fire resistance inferior to aluminum honeycomb panels, etc., to reduce the overall The effect of weight, ensuring the brightness of the light, improving the integrity and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

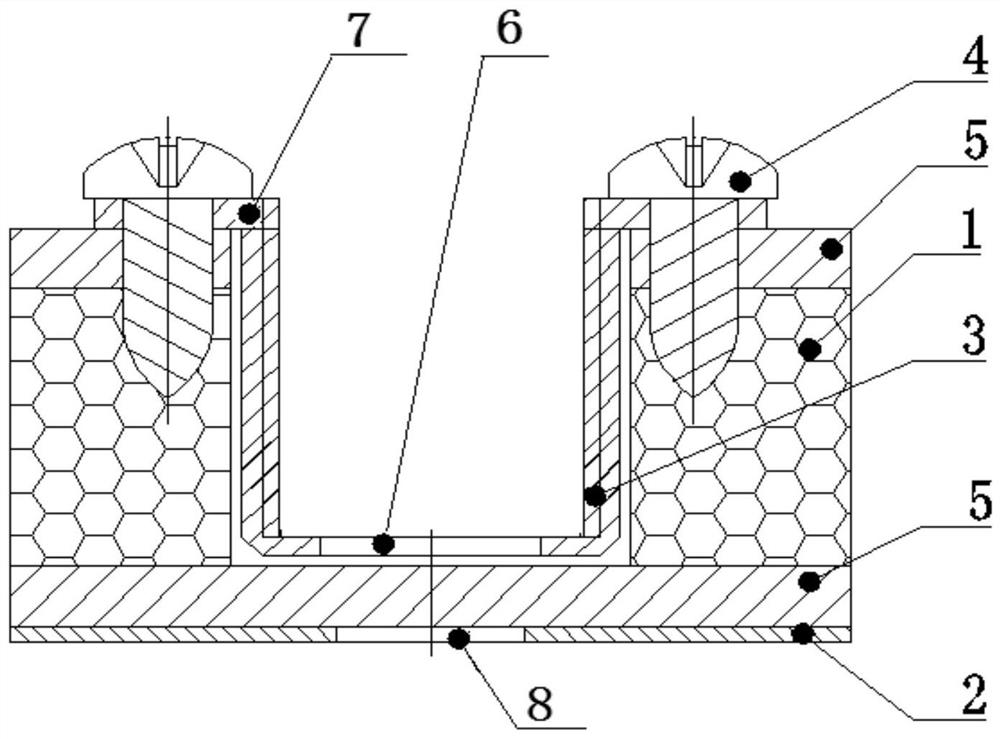

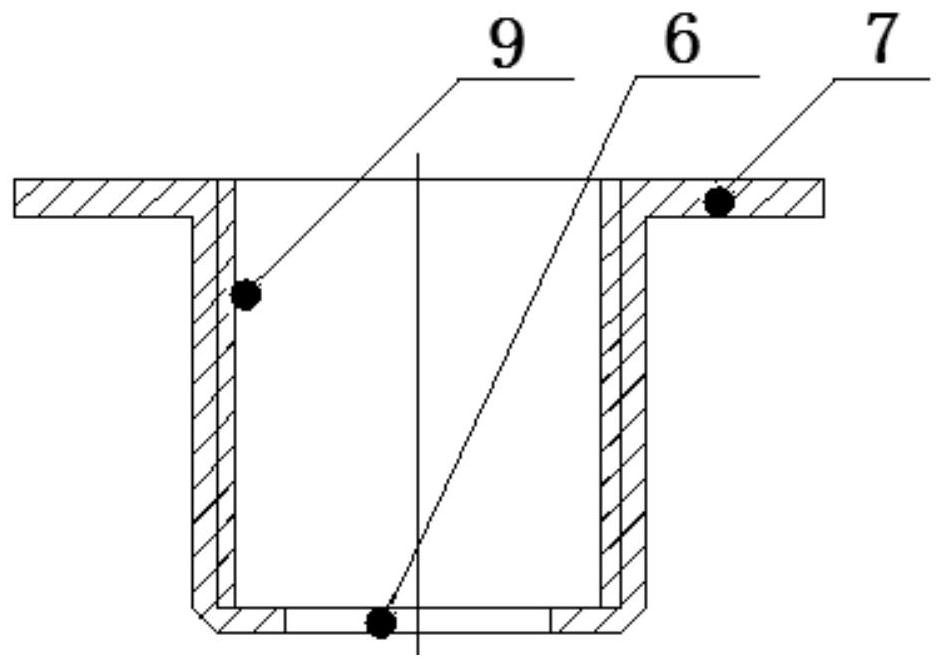

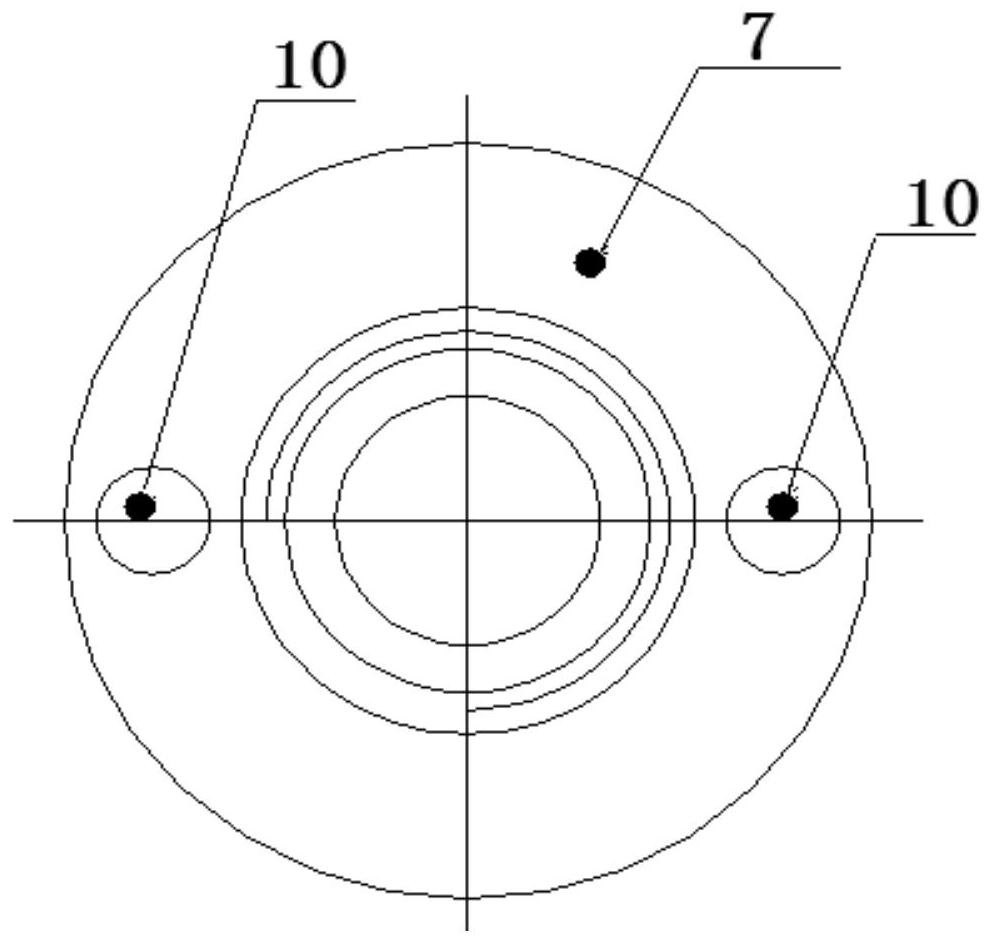

[0015] refer to Figure 1-Figure 3 , the following of the present invention is the outside of the flat top plate, that is, the exposed surface, and the top is the inside, that is, the back side of the flat top plate.

[0016] The specific embodiment of the present invention adopts the PC honeycomb composite board structure with a total thickness of 20mm, wherein the inner and outer sides are 3mm thick light-transmitting PC boards 5, and the middle layer is a 14mm thick phenolic foam honeycomb 1 as support. Under the premise of ensuring the strength and rigidity, the flat roof plate of this structure can effectively reduce the overall weight and realize the purpose of reducing the weight of the whole vehicle.

[0017] Both sides of the flat roof are 3mm thick light-transmitting PC boards, and a 0.2mm-thick opaque decorative film 2 is pasted on the exposed side. The decorative film partially adds light-transmitting holes 8 in the spotlight area to ensure the brightness of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com