Ball mill connecting shaft device

A ball mill and connecting shaft technology, applied in grain processing and other directions, can solve the problems of reducing the service life of mechanical equipment, large motor impact, and large power grid impact, and achieve the effect of relieving equipment vibration, small power grid impact, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

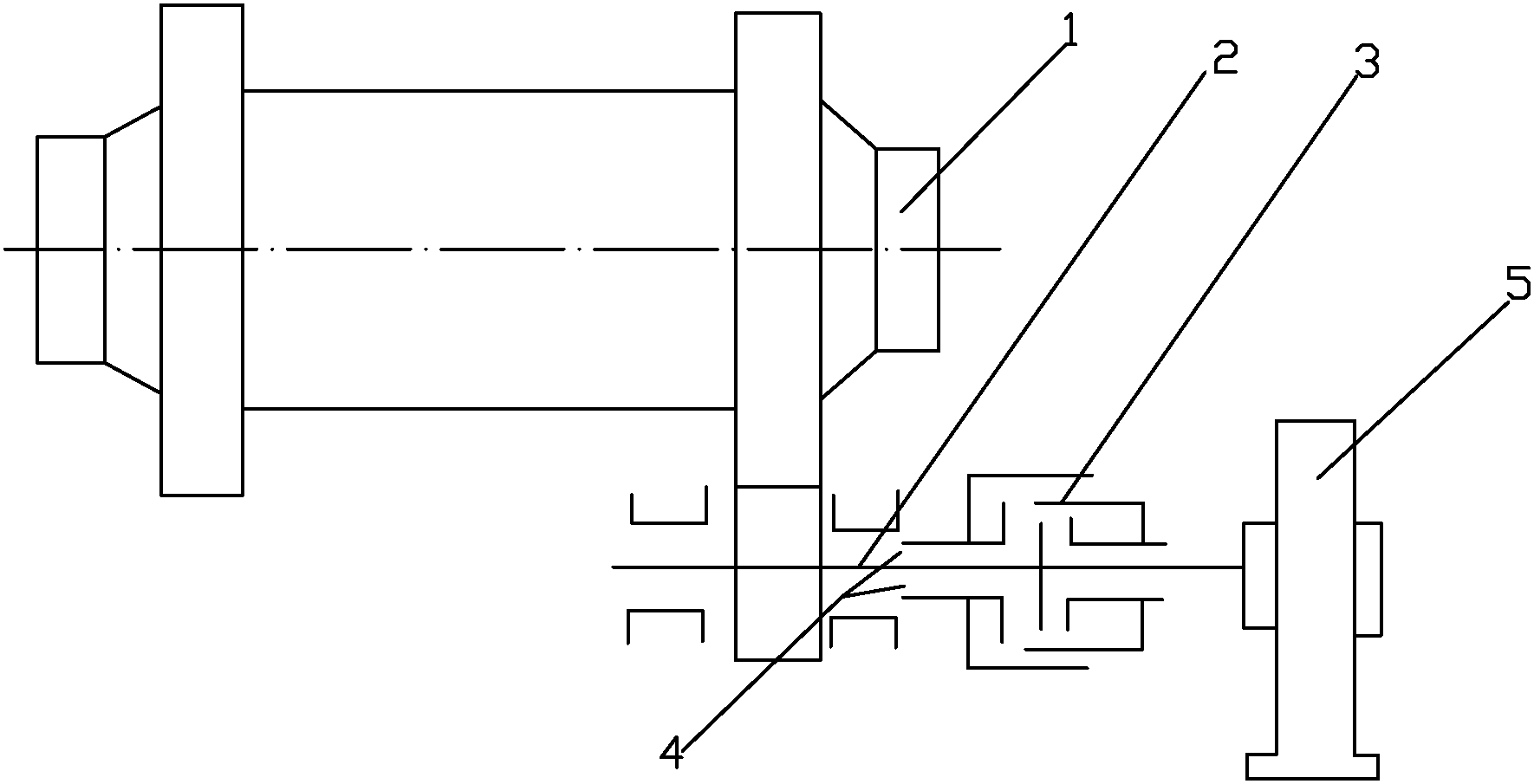

[0007] As shown in Figure 1, a ball mill coupling device of the present invention includes a ball mill 1, a drive shaft 2, an air clutch 3, and a synchronous motor 5, and the drive shaft 2 is connected with a ball mill 1, an air clutch 3, a synchronous motor 5, and the air pressure The clutch 3 is provided with an air pressure inlet and outlet 4, the transmission shaft 2 is connected to the gear of the ball mill 1, and the synchronous motor 5 is electrically controlled to drive the movement of the transmission shaft, but the air pressure clutch 3 drives the rotation of the transmission shaft 2 through the adjustment of the air pressure in the air pressure inlet and outlet , and finally the drive shaft 2 drives the ball mill to rotate through the meshing of the gears.

[0008] The above are only preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, some modifications and improvements can be made without departing from the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com