Desulphurization gypsum-polyurethane compounded fireproof and heat-preservation board and preparing method thereof

A technology of fireproof insulation board and desulfurized gypsum, which is applied in the field of insulation building materials, can solve the problems of low fireproof performance, poor insulation effect, high production cost, etc., and achieves small thermal conductivity, simple and easy-to-operate modification method, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

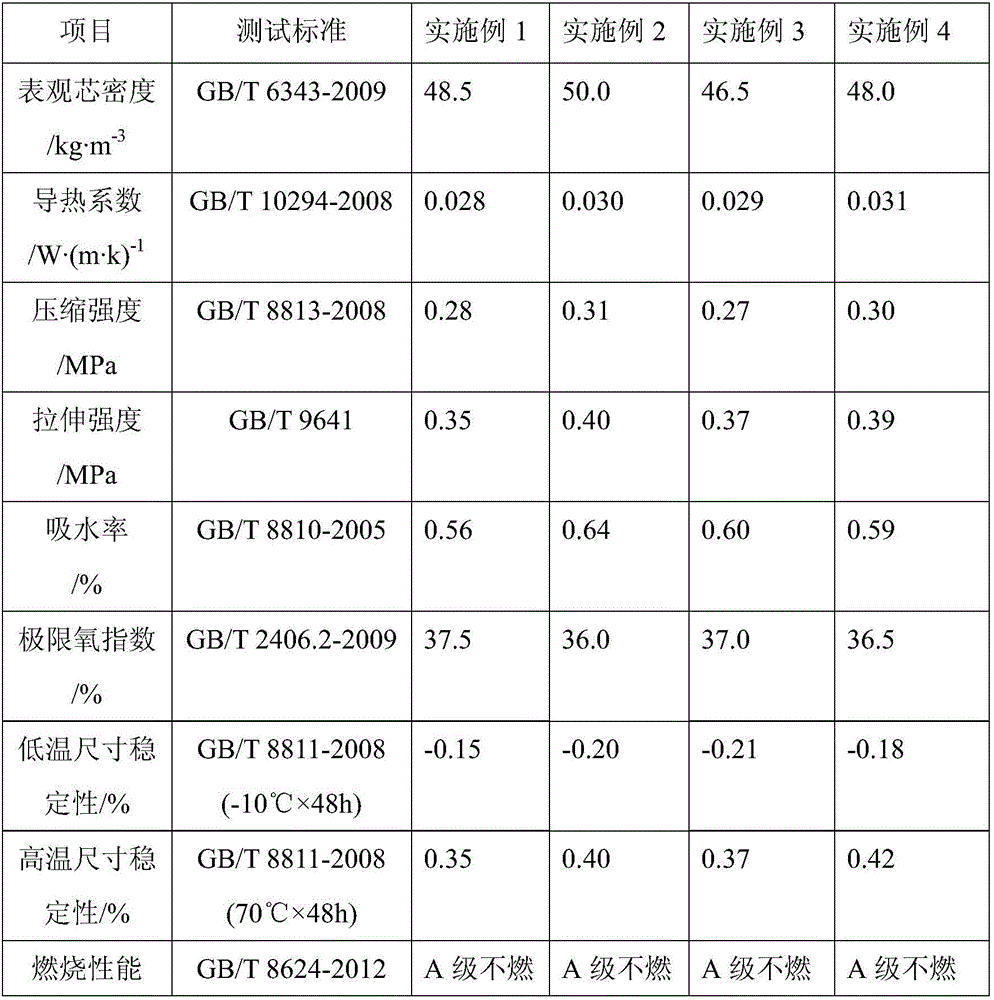

Examples

Embodiment 1

[0032] The raw material formula for preparing desulfurized gypsum-polyurethane composite fireproof insulation board is as follows: polyether polyol 403 (a company in Shandong): 30 parts, polyether polyol 4110 (a company in Shandong): 20 parts, polyester polyol 3152 (a company in Beijing) company): 10 parts, polypropylene glycol 1000 (a company in Shandong): 8 parts, structural flame-retardant polyol (self-made): 15 parts, modified desulfurized gypsum powder: 30 parts, foam stabilizer AK-8801 (a company in Jiangsu ) 1 part, foam stabilizer AK-8805 (a company in Jiangsu): 1 part, dibutyltin dilaurate (a company in Jiangsu): 0.5 parts, N, N-dimethylcyclohexylamine (a company in Zhejiang): 2 parts , tricresyl phosphate (TCP) (a company in Tianjin): 15 parts, HCFC-141B (a company in Shandong): 25 parts; polymethylene polyphenyl polyisocyanate: 150 parts.

Embodiment 2

[0034] The raw material formula for preparing desulfurized gypsum-polyurethane composite fireproof insulation board is as follows: polyether polyol 635C (a company in Shandong): 10 parts, polyether polyol 380 (a company in Shandong): 20 parts, polyether polyol 403 (a company in Shandong) Company): 10 parts, polyester polyol P-455N (a company in Beijing): 10 parts, polyester polyol SKR-400E (a company in Beijing): 10 parts, polypropylene glycol 1000 (a company in Shandong): 6 parts, Structural flame retardant polyol (self-made): 22 parts, modified desulfurized gypsum powder: 40 parts, foam stabilizer AK-8812 (a company in Jiangsu) 1.5 parts, foam stabilizer AK-8805 (a company in Jiangsu) 0.5 parts, Foam stabilizer HK-102 (a company in Shandong): 0.5 part, stannous octoate (a company in Jiangsu): 1 part, 1,3,5-tris(dimethylaminopropyl) hexahydrotriazine (a company in Jiangsu): 3 parts, dimethyl methylphosphonate (DMMP) (a company in Shenzhen): 20 parts, cyclopentane (a company i...

Embodiment 3

[0036] The raw material formula for preparing desulfurized gypsum-polyurethane composite fireproof insulation board is as follows: polyether polyol 4110 (a company in Shandong): 20 parts, polyether polyol 380 (a company in Shandong): 5 parts, polyether polyol 403 (a company in Shandong) Company): 5 parts, polyether polyol 635C (a company in Shandong): 20 parts, polyester polyol 3152 (a company in Beijing): 15 parts, polypropylene glycol 1000 (a company in Shandong): 5 parts, structural flame retardant Polyol (self-made): 25 parts, modified desulfurized gypsum powder: 35 parts, foam stabilizer polyether modified silicone oil HK-102 (a company in Shandong) 3.5 parts, stannous octoate (a company in Jiangsu): 0.5 parts, two Dibutyltin laurate (a company in Jiangsu): 1.5 parts, pentamethyldiethylenetriamine (a company in Jiangsu): 1 part, tetraphenylresorcinol bispolyphosphate (RDP) (a company in Guangdong): 10 parts Parts, fluorodichloroethane HCFC-141B (a company in Shandong): 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com