Polyolefin foaming material recycling method and device

A polyolefin foaming and material recycling technology, applied in mechanical material recycling, recycling technology, plastic recycling, etc., can solve the problems of inability to recycle recycled materials, waste accumulation, environmental pollution, economic and environmental pressure, etc., and achieve considerable Economic and social value, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for recycling polyolefin foamed materials, the method may further comprise the steps:

[0033] (1) The polyolefin foam material to be recycled is crushed, and the diameter of the sheet after crushing the polyolefin foam material ranges from 0.1cm to 15cm;

[0034] The diameter range in step (1) is an optimal solution, which is beneficial to the subsequent molding process. Of course, polyolefin foam materials can also be recycled if the diameter is smaller or larger than this range, but it is relatively difficult to combine molding.

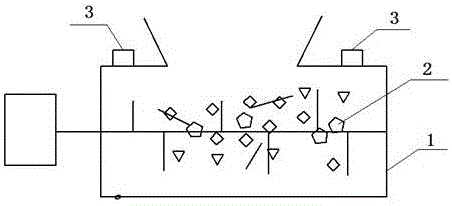

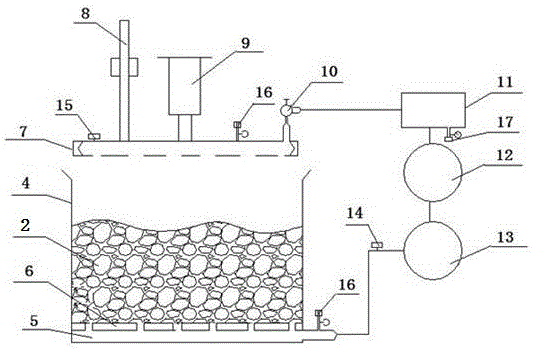

[0035] (2) Put the pulverized polyolefin foam material into the mixer 1 for stirring, and spray the adhesive continuously during the stirring process to form the ready-to-use material 2, wherein the pulverized polyolefin foam material in the mixer 1 , The mass-to-number ratio of the adhesive is: 100:25;

[0036] In this embodiment, the preferred adhesive is ethylene-vinyl acetate copolymer resin micropowder, and the mixer 1 in ste...

Embodiment 2

[0047] This embodiment differs from Embodiment 1 in that:

[0048] In step (1), the diameter of the pulverized polyolefin foam sheet is between 0.1 cm and 5 cm;

[0049] In step (2), the adhesive and reinforcing fiber are continuously sprayed during the stirring process to form the ready-to-use material 2, wherein the quality of the pulverized polyolefin foam material, adhesive and reinforcing fiber in the mixer 1 is The ratio of copies is: 100:20:5;

[0050] As mentioned above, when the final product requires high tension properties, the requirement can be met by adding reinforcing fibers during the stirring process. The preferred adhesive is liquid adhesive, and the reinforcing fibers are chopped natural fibers.

[0051] In step (3), the heating temperature is 85°C.

[0052] In step (4), the material 2 to be formed is cooled to below 80°C.

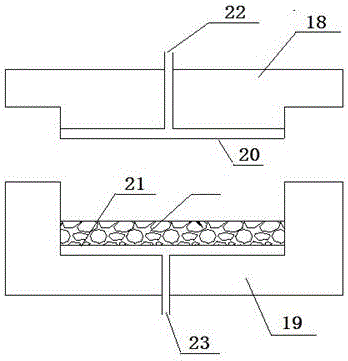

[0053] The difference from Embodiment 1 is that the heated and pressurized container in this embodiment is preferably a compression ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com