Fired brick and preparation method thereof

A technology for sintering bricks and formulations, applied in the fields of resources, environment and building materials, can solve problems such as compressive strength and weathering resistance that cannot meet requirements, and achieve the effects of protecting the environment, reducing consumption, and improving plasticity index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The raw materials of fired bricks are as follows:

[0066]

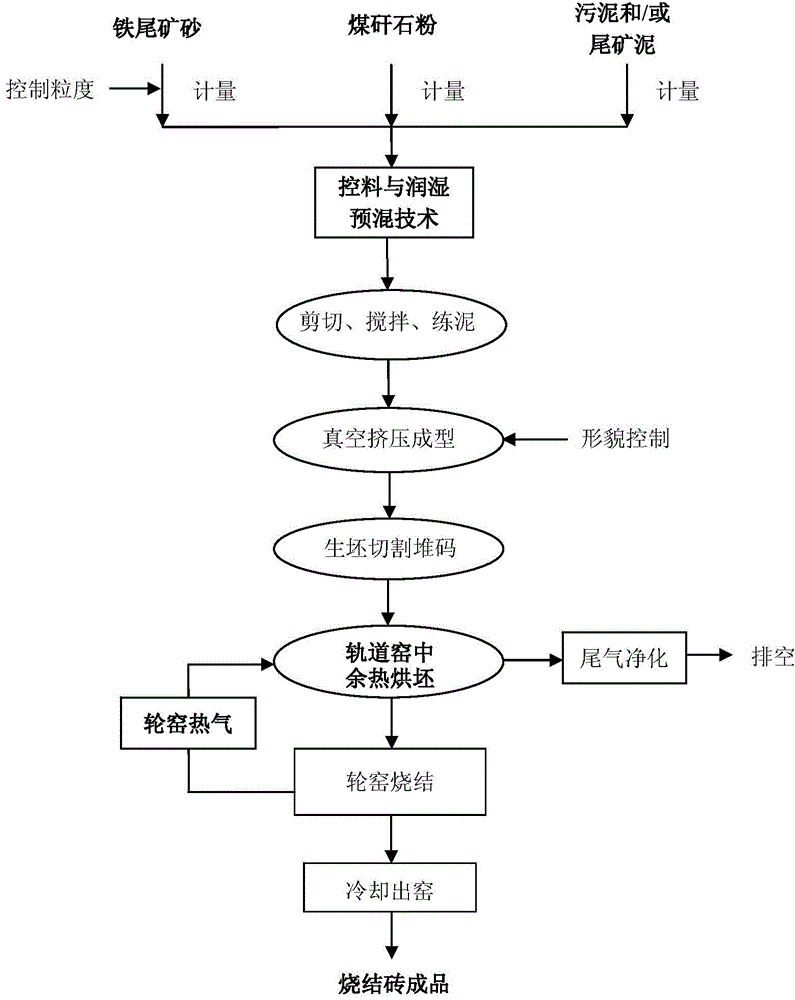

[0067] The production method of described sintered brick, comprises the steps:

[0068] (1) Mix 60 parts of magnetite tailings with a particle size of less than 7.0 mm and 40 parts of coal gangue powder with a particle size of less than 3.0 mm, then add 3 parts of sludge and 13 parts of water, after wetting and premixing, Send it into the mud refining machine for mixing, stirring, and mud refining to obtain the raw material of fired bricks;

[0069] (2) Put the sintered brick raw material into the brick making machine and vacuum extrude it into a green body. The shape of the green body is a cuboid. After cutting and stacking, the green body is sent to the orbital kiln and dried by the exhaust gas of the wheel kiln at 180°C. Dry for 5 hours to obtain a dry green body, and the tail gas generated during the drying process is purified and then emptied;

[0070] (3) Put the dry body into the wheel kiln, sinter...

Embodiment 2

[0072] The raw materials of fired bricks are as follows:

[0073]

[0074] The production method of described sintered brick, comprises the steps:

[0075] (1) 75 parts of ultra-poor vanadium-titanium magnetite sand with a particle size of less than 10.0mm and 25 parts of coal gangue powder with a particle size of less than 2.0mm are mixed, then add 2 parts of sludge, 2 parts of tailings mud and 10 parts of water, through After wetting and pre-mixing, send it to the mud mixer for mixing, stirring, and mud refining to obtain the raw materials for sintered bricks;

[0076] (2) Put the sintered brick raw material into the brick making machine and vacuum extrude it into a green body. The shape of the green body is round. After cutting and stacking, the green body is sent to the orbital kiln and passed through the exhaust gas of the wheel kiln at 190°C Dry for 4 hours to obtain a dry green body, and the tail gas generated during the drying process is purified and then emptied; ...

Embodiment 3

[0079] The raw materials of fired bricks are as follows:

[0080]

[0081] The production method of described sintered brick, comprises the steps:

[0082] (1) Mix 80 parts of hematite tailings with a particle size of less than 8.0mm and 20 parts of coal gangue powder with a particle size of less than 5.0mm, then add 1.2 parts of sludge, 4.8 parts of tailings mud and 15 parts of water, and moisten Wet, after premixing, send it to the mud mixer for mixing, stirring, and mud refining to obtain raw materials for fired bricks;

[0083] (2) Put the sintered brick raw material into the brick making machine and vacuum extrude it into a green body. The shape of the green body is round. After cutting and stacking, the green body is sent to the orbital kiln and passed through the exhaust gas of the wheel kiln at 200°C. Dry for 2 hours to obtain a dry body, and the tail gas generated during the drying process is purified and then emptied;

[0084] (3) Put the dry body into the wheel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com