Method for preparing electric deposited cobalt

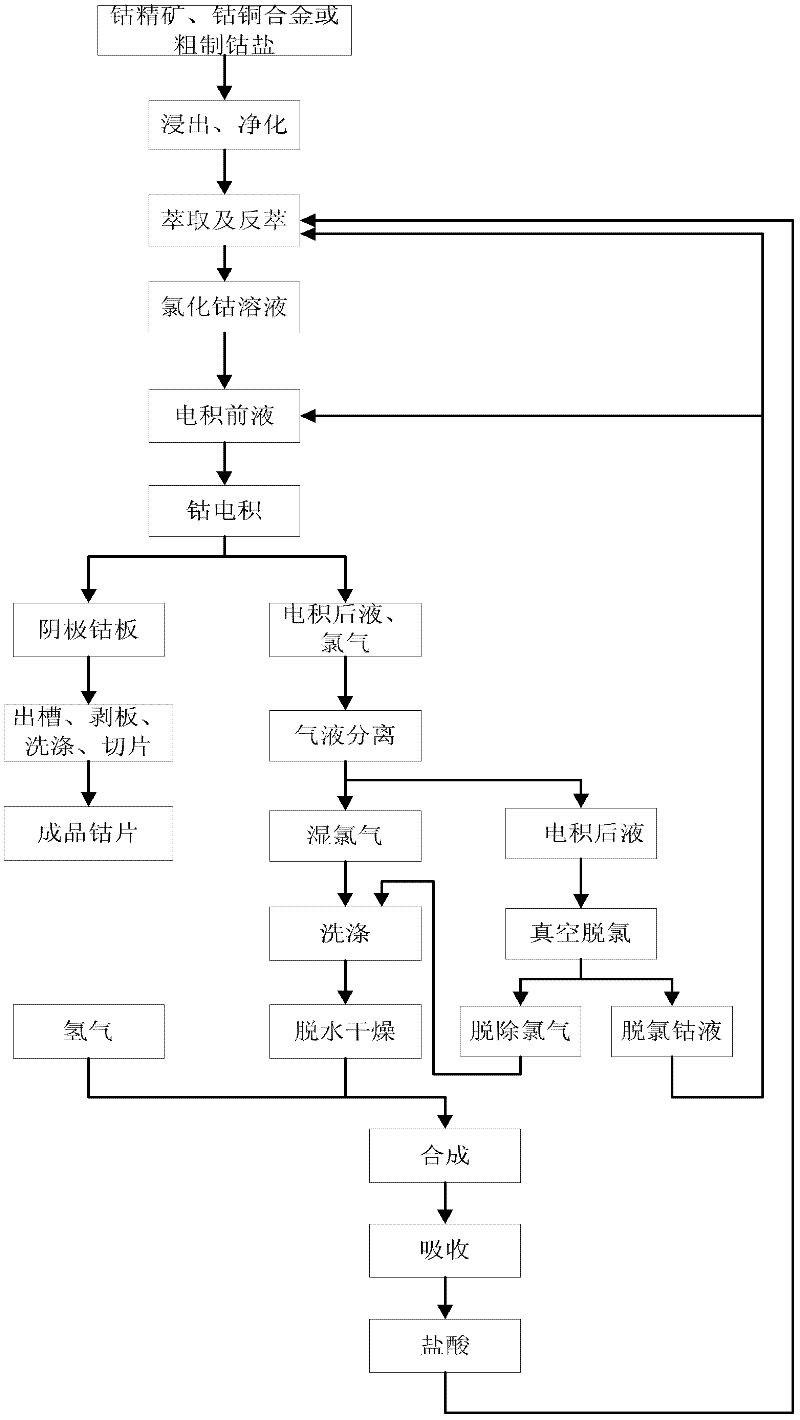

An electrowinning and roughing technology, which is used in the field of electrowinning cobalt produced by the hydrochloric acid cycle, can solve the problems of environmental danger, environmental pollution, a large amount of chlorine gas, etc., and achieve the effects of avoiding pollution, high purity, and reducing anti-corrosion pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Cobalt concentrate, cobalt-copper alloy or crude cobalt salt are used as raw materials, and sulfuric acid is used for leaching. After the leaching solution is decoppered and iron removed, it is extracted with P204 extractant to remove impurities; then the cobalt is extracted with P507 extractant, and back-extracted with hydrochloric acid. Obtain cobalt chloride solution, after degreasing, obtain Co 100-160g / L, remaining metal impurity≤0.001g / L, the cobalt chloride solution of oil content≤0.001g / L, and the electrodeposition liquid of low concentration (Co 40-60g / L) mixed to obtain Co80-100g / L cobalt chloride solution, as the solution before electrowinning; electrowinning is carried out in a closed electrolytic cell, and the pH of the controlled electrowinning is 1-2, and the temperature is 50- 55°C, current density of 430-500A / m2, cell voltage of 2.6-3.0V, etc., to obtain electro-deposited cobalt, after electro-deposited cobalt goes out of the tank, stripped, washed and s...

Embodiment 2

[0021] Cobalt concentrate, cobalt-copper alloy or crude cobalt salt are used as raw materials, and sulfuric acid is used for leaching. After the leaching solution is decoppered and iron removed, it is extracted with P204 extractant to remove impurities; then the cobalt is extracted with P507 extractant, and back-extracted with hydrochloric acid. Obtain the cobalt chloride solution, after degreasing, obtain the cobalt chloride solution of Co 120-160g / L, remaining metal impurity≤0.001g / L, oil content≤0.001g / L, and the electrodeposition liquid of low concentration (Co 40-50g / L) mixed to obtain Co80-100g / L cobalt chloride solution, as the solution before electrowinning; electrowinning is carried out in a closed electrolytic cell, and the pH of the controlled electrowinning is 1-2, and the temperature is 50- 55°C, current density of 430-500A / m2, cell voltage of 2.5-3.0V, etc., to obtain electro-deposited cobalt, after electro-deposited cobalt goes out of the tank, stripped, washed a...

Embodiment 3

[0023] Using cobalt concentrate, cobalt-copper alloy or crude cobalt salt as raw materials, leaching with hydrochloric acid, after decopper and iron removal, use P204 extraction to remove impurities; then use P507 extraction to extract cobalt, and back-extract with hydrochloric acid to obtain cobalt chloride solution , after oil removal, a cobalt chloride solution with Co100-160g / L, other metal impurities ≤0.001g / L, oil content ≤0.001g / L is obtained, and a low-concentration electrolytic solution (Co 40-60g / L) Mix to obtain a cobalt chloride solution of Co 80-100g / L as the pre-electrowinning solution; conduct electrowinning in a closed electrolytic cell, control the electrowinning pH to 1-2, the temperature to 50-55°C, and the current density 430-480A / m2, cell voltage 2.5-3.0V and other conditions, to obtain electro-deposited cobalt, after the electro-deposited cobalt goes out of the tank, stripping, washing and slicing, the finished cobalt flakes with a Co% of 99.988% are obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com