Coking coal pretreatment method and special device thereof

A special equipment and coking coal technology, which is applied in the field of coking coal pretreatment, can solve the problems affecting coke output, quality, coke oven operation and life, and achieve reduction of coke oven residual ammonia water and wastewater treatment volume, coke strength improvement, The effect of reducing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

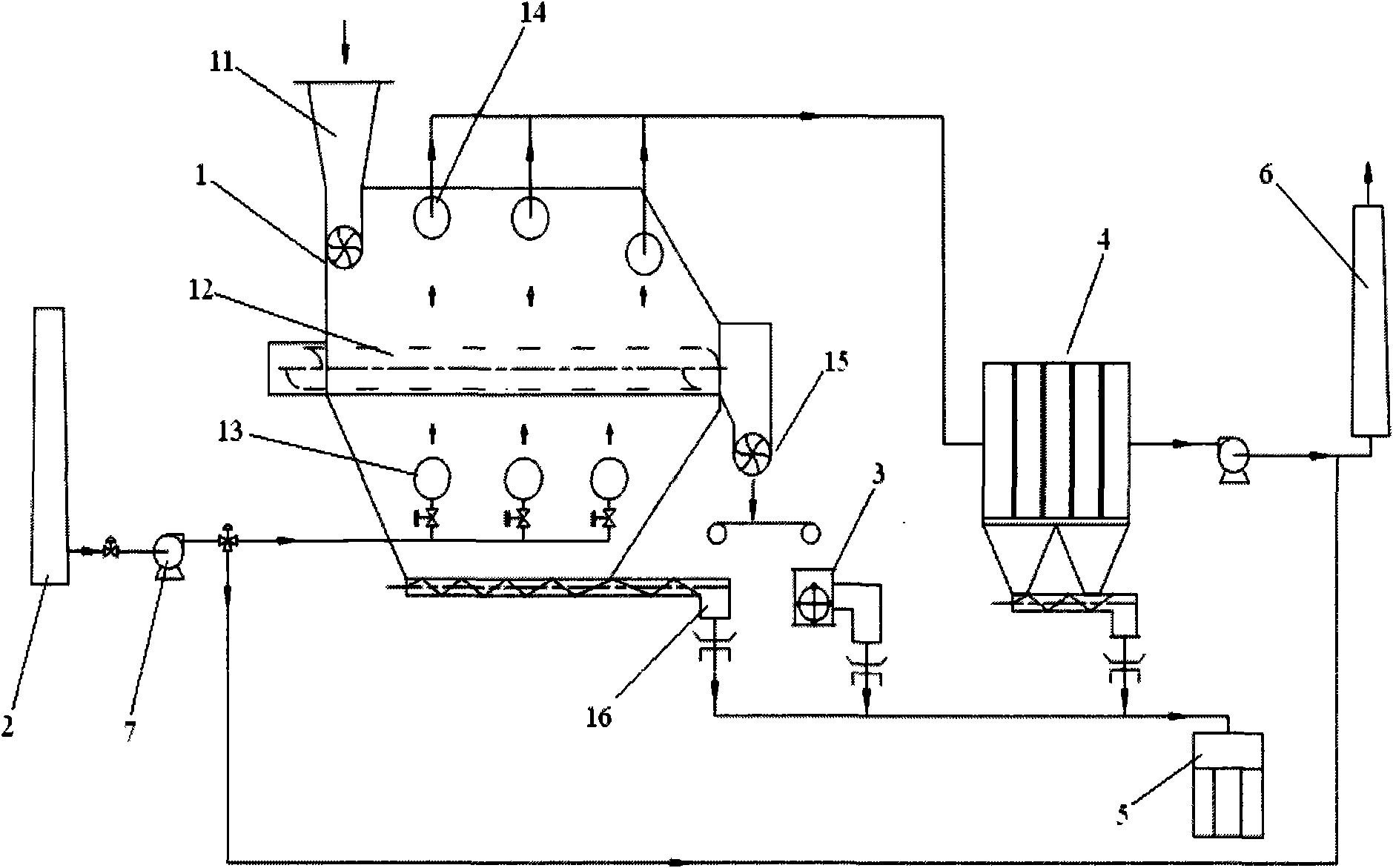

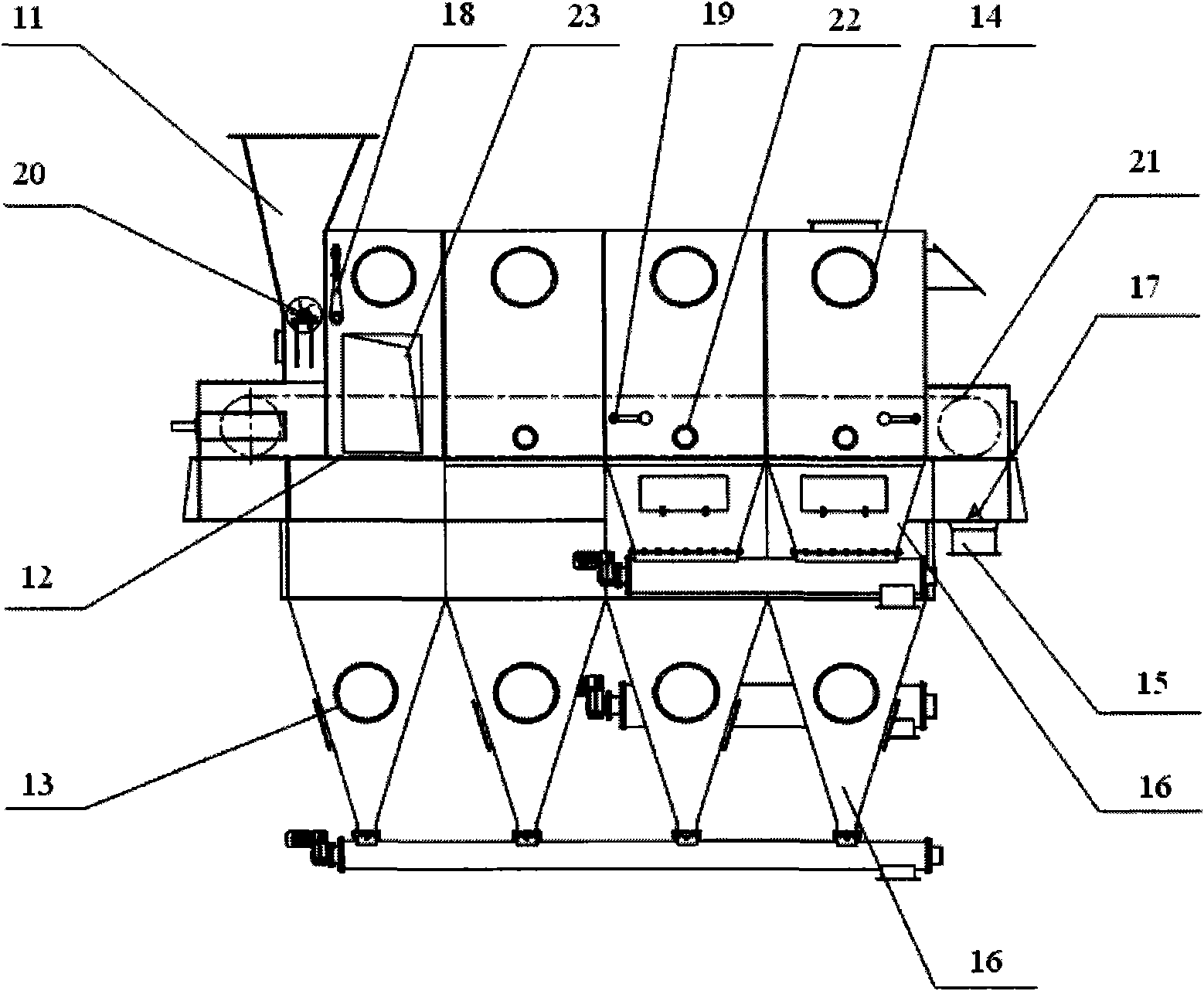

[0019] Such as figure 1 Shown is a schematic process flow diagram of the coking coal pretreatment method of the present invention. The coking coal is transported to the humidity-adjusting and classifying bed by the belt conveyor, and the coal material is on the humidity-adjusting and classifying bed, blown by coke oven flue gas or other waste heat gas at 180°C to 220°C under the bed, and the solid coal is in a fluid state It realizes the classification and separation of coking coal and moisture control (coal humidity control) treatment. Due to the different particle size and quality of the coal, on the bed, the small particle coal of ≤3mm is blown up by the hot air, and falls into the fine particle coal collection hopper at the lower part of both sides of the bed, and is transported by the screw conveyor and the belt conveyor. To the coal tower; the large particle co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com