Method for preparing aluminum-magnesium silicate from fly ash

A magnesium-aluminum silicate and fly ash technology, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of limited source of raw materials, and the output and cost of magnesium-aluminum sulfate products cannot meet the demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

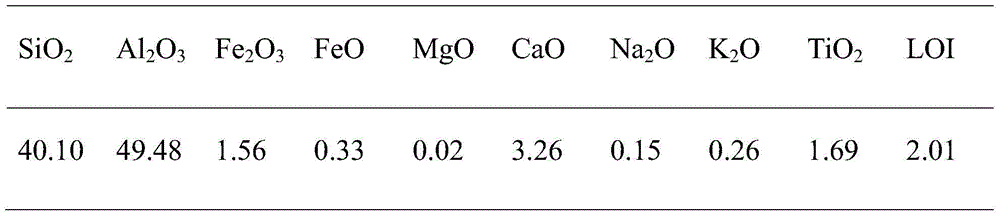

[0034] (1) 600ml concentration is in the sodium hydroxide of 20% by weight, joins in the fly ash of 200g main components as shown in Table 1 (the weight ratio of fly ash and described alkaline solution is 1:4.2), Stir evenly, place in a mechanically stirred reactor, screw on the seal cover of the reactor and turn on the heating and stirring button (stirring rate is 150rpm). The temperature was set at 110° C., and the reaction time was 1 hour. After the reaction is over, cooling water is introduced at the same time to rapidly cool down the kettle body. When the temperature in the kettle was lowered to room temperature, the lid of the kettle was unscrewed, and the reaction slurry was poured out. After vacuum filtration, the pre-desilication solution (the composition is shown in Table 2 below) and the silicon extraction residue were obtained;

[0035] (2) The silicon extraction residue obtained in step (1) is mixed with calcium oxide and sodium carbonate, and the ratio is: rela...

Embodiment 2

[0045] (1) 680ml concentration is in the sodium hydroxide of 15% by weight, joins in the fly ash of 200g main components as shown in Table 1 (the weight ratio of fly ash and described alkaline solution is 1:5.5), Stir evenly, place in a mechanically stirred reactor, screw on the seal cover of the reactor and turn on the heating and stirring button (stirring rate is 150rpm). The temperature was set at 95°C and the reaction time was 30 minutes. After the reaction is over, cooling water is introduced at the same time to rapidly cool down the kettle body. When the temperature in the kettle was lowered to room temperature, the lid of the kettle was unscrewed, and the reaction slurry was poured out. After vacuum filtration, the pre-desiliconization solution (the composition is shown in Table 2 below) and the silicon extraction residue were obtained. The silicon extraction residue was washed 4 times with hot water, and dried in an electric blast drying oven at 120 for 8 hours;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com