Technological method for recycling lithium from lithium-containing waste liquid of medicine and synthetic plastics industries

A process method and waste liquid technology, applied in the direction of lithium halide, lithium carbonate;/acid carbonate, etc., to achieve the effect of resource conservation, saving rare resources, and easy industrialization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

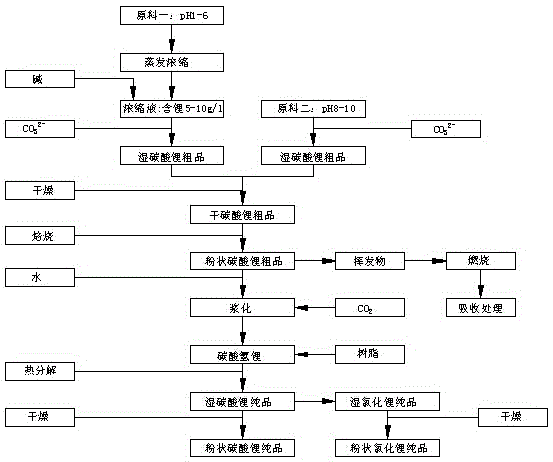

Image

Examples

Embodiment 1

[0025] Pharmaceutical and synthetic plastic lithium-containing waste liquid raw material 1 contains 2.5g / l lithium and a pH value of 3.6. After evaporation and concentration, the lithium concentration becomes 9g / l and the pH value becomes 2.4; add sodium hydroxide to adjust the pH value to 9.5; adding an appropriate amount of sodium carbonate and then filtering; drying the filter residue at 65°C; roasting the dried filter residue at 400°C for 1.5h; passing the roasted volatiles into an incinerator for combustion treatment at 1100°C; The filter residue is slurried with water, acidified by passing into carbon dioxide; the acidification solution is passed into an anion and cation mixed resin bed for purification; the purification solution is heated and decomposed to obtain lithium carbonate precipitation, washed three times with pure water, and centrifuged to obtain pure wet lithium carbonate; The pure product of lithium carbonate is the pure product of powdery lithium carbonate, ...

Embodiment 2

[0027] Pharmaceutical and synthetic plastic lithium-containing waste liquid raw material 1, containing lithium 2g / l, pH value is 4.2, after concentrated by evaporator, lithium concentration becomes 10g / l, pH value becomes 3.6; add sodium hydroxide and sodium carbonate Adjust the pH value to 8.5 with mixed alkali; filter after feeding an appropriate amount of carbon dioxide; dry the filter residue at 75°C; roast the dried filter residue at 415°C for 2 hours; Slurry the filter residue roasted at 415°C with water, pass through carbon dioxide to acidify; pass the acidified solution into a chelating resin bed for purification; heat and decompose the purified solution to obtain lithium carbonate precipitation, wash with pure water three times, and centrifuge to obtain pure wet lithium carbonate; The pure wet lithium carbonate is dried to obtain the pure powdery lithium carbonate. The main content of lithium carbonate is 93.2%.

Embodiment 3

[0029] Lithium-containing waste liquid raw materials for pharmaceuticals and synthetic plastics No. 2, lithium content 8.5g / l, pH value 8.8, add appropriate amount of sodium carbonate and filter; filter residue is dried at 60°C; dried filter residue is roasted at 450°C for 1.5 h; Roasting volatiles are fed into an incinerator for combustion treatment at 1150°C; the filter residue roasted at 450°C is slurried with water, and then acidified with carbon dioxide; the acidification solution is passed into a chelating resin bed for purification; the purification solution is heated and decomposed to obtain lithium carbonate precipitation , washed three times with pure water, and centrifuged to obtain pure wet lithium carbonate; the pure wet lithium carbonate was acidified by adding hydrochloric acid, separated by concentrated crystallization, and dried to obtain pure powdery anhydrous lithium chloride. The main content of lithium chloride was 99.2%, the detection meets the requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com