Deep comprehensive resource utilization method for electrolytic cell overhaul slag

A technology for overhauling slag and electrolytic cells, which is applied in the electrolysis process, electrolysis components, and solid waste removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 of the present invention. The method for deep resource utilization and comprehensive utilization of electrolyzer overhaul slag comprises the following steps:

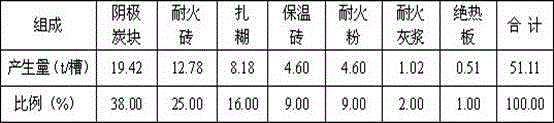

[0033] a. Sorting the slag from the overhaul of the electrolytic cell to obtain electrolyte blocks, cathode rods, waste cathode carbon blocks, waste refractory bricks, waste heat insulation bricks, waste heat insulation boards, waste paste, and the remaining mixed slag. Among them, the electrolyte block material is mainly aluminum, which can be directly recycled to the electrolytic aluminum plant, and the cathode rod is iron rod, which can also be directly recycled.

[0034]b. Carry out water immersion to waste cathode carbon block, fluoride salt is dissolved in water, and the cathode carbon block that has absorbed fluoride salt will disperse, obtain the powder material and block material that immerse and disperse, select the block material among them, The selected block material has less fluoride s...

Embodiment 2

[0041] Embodiment 2 of the present invention. The method for deep resource utilization and comprehensive utilization of electrolyzer overhaul slag comprises the following steps:

[0042] a. Sorting the overhaul slag of the electrolytic cell to obtain electrolyte blocks, cathode rods, waste cathode carbon blocks, waste refractory bricks, waste heat insulation bricks, waste heat insulation boards, waste paste, and the remaining mixed slag.

[0043] b. Soak the waste cathode carbon block in water for 2-3 days to obtain soaked and dispersed powder and block material, select the block material with a particle size greater than 5 cm, and crush the selected block material to a particle size of 2 cm , water immersion again, select the block material with a particle size greater than 1 cm, as the aggregate for making the cathode carbon block, and the remaining powder is ground and floated to obtain carbon powder. The obtained cathode carbon block aggregate and carbon powder are dried ...

Embodiment 3

[0050] Embodiment 3 of the present invention. The method for deep resource utilization and comprehensive utilization of electrolyzer overhaul slag comprises the following steps:

[0051] a. Sorting the overhaul slag of the electrolytic cell to obtain electrolyte blocks, cathode rods, waste cathode carbon blocks, waste refractory bricks, waste heat insulation bricks, waste heat insulation boards, waste paste, and the remaining mixed slag.

[0052] b. Soak the waste cathode carbon block in water for 2-3 days to obtain soaked and dispersed powder and block material, select the block material with a particle size greater than 1 cm, and crush the selected block material to a particle size of 0.5 cm , water immersion again, select the blocks with a particle size greater than 0.3 cm, dry them as aggregates for making cathode carbon blocks, and grind the remaining powders and flotation to obtain carbon powder. The obtained cathode carbon block aggregate and carbon powder are dried an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com