Recovery and comprehensive utilization method of heavy metals in stainless steel pickling wastewater sludge

A technology of pickling wastewater sludge and recovery method, which is applied in water/sludge/sewage treatment, sludge treatment, chromium oxide/hydrate, etc., and can solve the difficulty of increasing the comprehensive utilization of wastewater heavy metal sludge and the fluctuation of metal content Large-scale, secondary pollution of the ecological environment and other problems, to achieve the effects of environmental protection and resource conservation, comprehensive utilization, resource utilization and comprehensive utilization, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

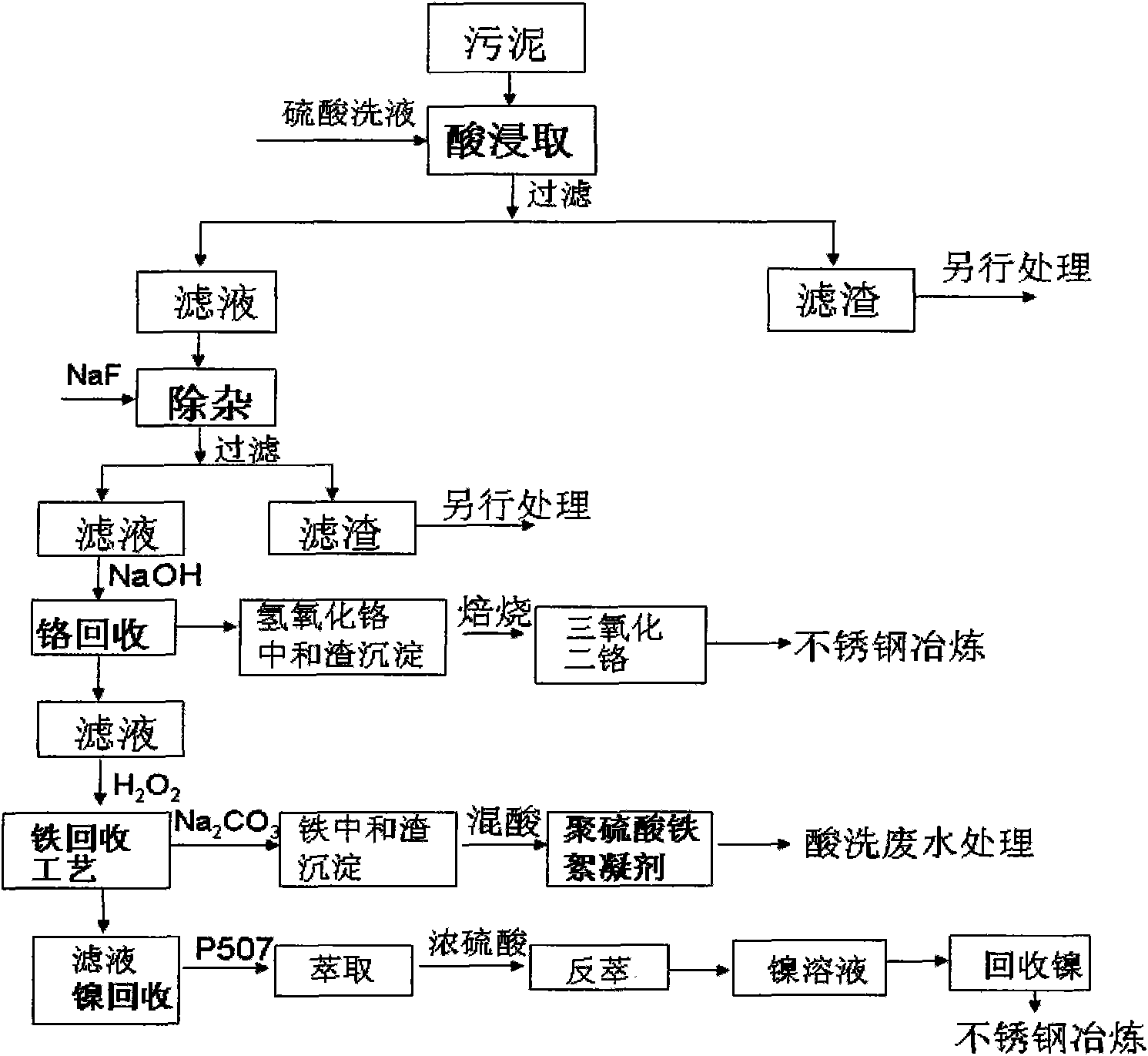

[0029] The present invention uses a wet process to treat sludge from stainless steel pickling wastewater. The process flow mainly includes acid leaching, neutralization, precipitation, and extraction, and the recovered heavy metals are used in stainless steel smelting, and the steps are as follows:

[0030] (1) Put the heavy metal sludge in the first reaction kettle, add waste pickling solution, stir, and control the pH at the end point within the range of 1.0 to 1.5, fully leaching the reaction, filtering, and pumping the filtrate into the second reaction In the tank, the filter residue is treated separately.

[0031] (2) Add sodium fluoride solution to the second reaction tank, adjust the pH of the solution in the range of 4.0 to 4.5, fully react, filter, pump the filtrate into the third reaction tank, and process the filter residue separately. This step will remove calcium, magnesium, aluminum impurities in the filtrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com