New process for extracting high-purity gardenia yellow pigment by membrane separation and purification technology

A technology for separation of gardenia yellow pigment and membrane, which is applied in the field of extraction technology of gardenia yellow pigment, can solve the problems of waste liquid pollution process, high energy consumption in the production process, high production cost, etc., and achieve high extraction efficiency and low production cost. The effect of low and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

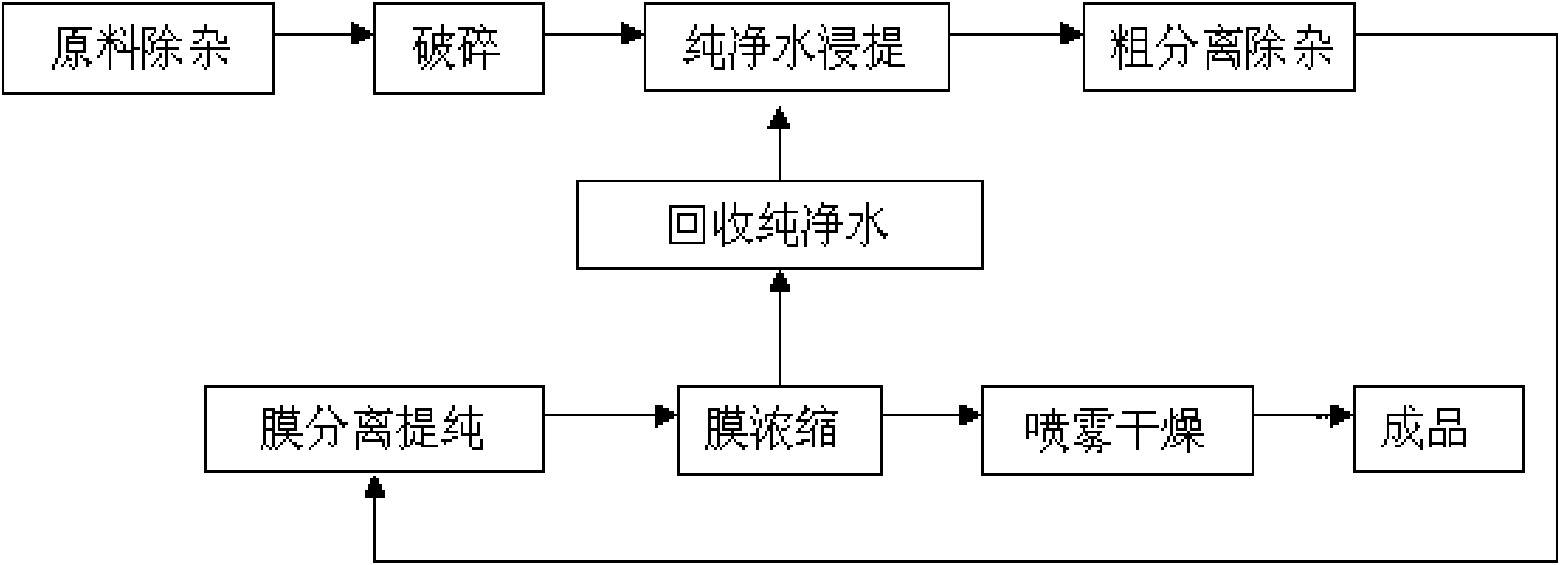

[0019] A new process for extracting high-purity gardenia yellow pigment by membrane separation and purification technology (see figure 1 ), including the following steps:

[0020] (1) Pure water leaching: first wash the gardenia to remove impurities, then crush it into 1-3mm particles, then add pure water 8-12 times the weight of gardenia, add 0.0001-0.0002 Add pectinase and protease to the U enzyme meter, extract 2 to 3 times at a temperature of 45 to 55 ° C, each time for 4 hours, and combine the extracts;

[0021] (2) Coarse separation and impurity removal: the extract is separated through a flat plate centrifuge, a horizontal screw centrifuge and a disc centrifuge in order to remove the solid suspended matter of gardenia slag and gardenia oil in the extract , to obtain a clear and transparent extract for the next process, and to recover and comprehensively utilize gardenia residue and gardenia oil;

[0022] (3) Membrane separation and purification: the extract separated ...

Embodiment 2

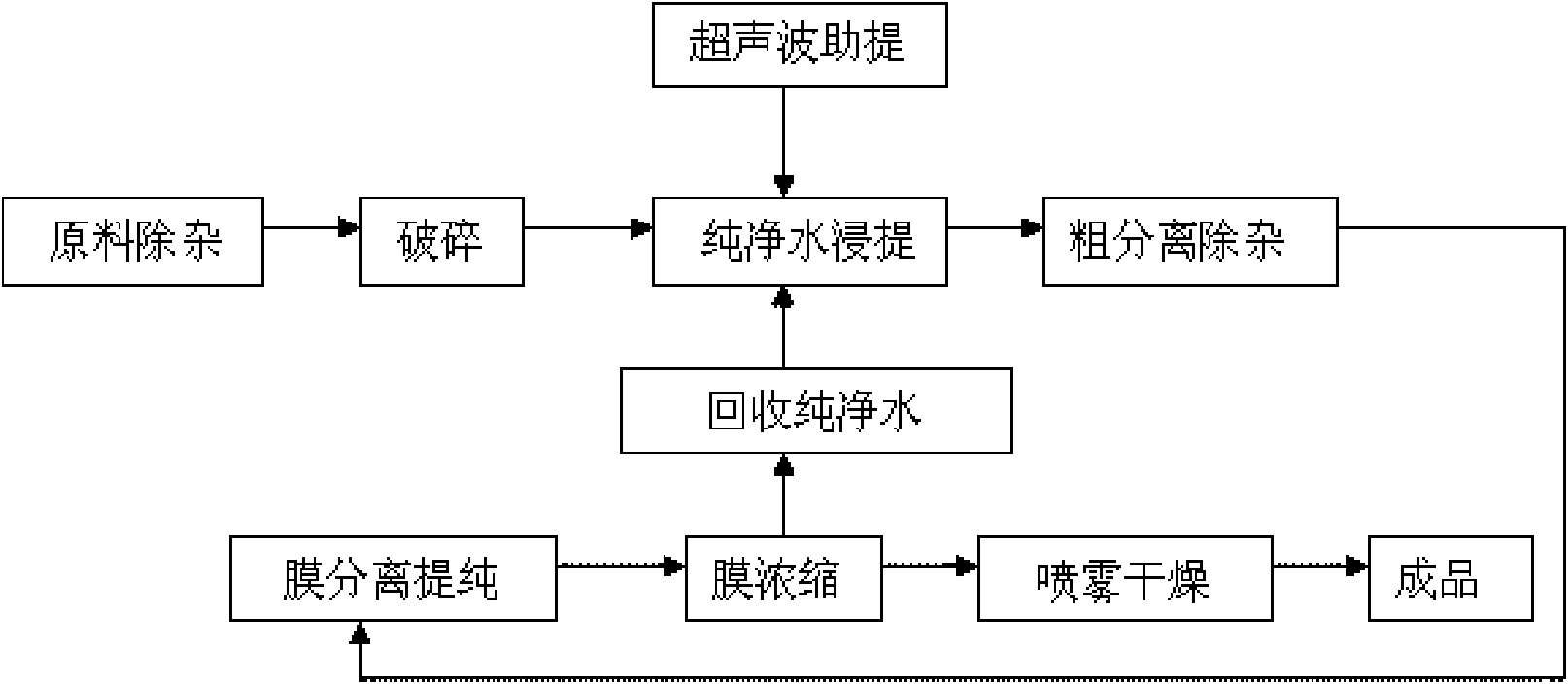

[0025] A new process for extracting high-purity gardenia yellow pigment by membrane separation and purification technology (see figure 2 ), its basic operation steps are the same as embodiment one, and the difference is: in step (1), add ultrasonic to help lift, and its concrete operation steps are as follows:

[0026] (1) Extraction with pure water: first wash and remove gardenia, then crush it into 1-3mm particles, add it to the extraction equipment, and then add pure water 8-12 times the weight of gardenia, according to each gram of raw material Add 0.0001~0.0002U pectinase to gardenia and add 0.0001~0.0002U protease to each gram of raw material gardenia. Add pectinase and protease respectively. Underleaching 2 to 3 times, 2 hours each time, and combining the extracts;

[0027] (2) Coarse separation and impurity removal: its concrete operation steps are with embodiment one;

[0028] (3) Membrane separation and purification: its concrete operation steps are with embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com