Carbonization and activation integrated activated carbon production method and equipment

A technology for the production and production of activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., and can solve the problems of inability to produce coal-based activated carbon, high requirements for heat resistance of equipment materials, and difficulty in process control and adjustment. Achieve the effect of low cost, simple structure, and expansion of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

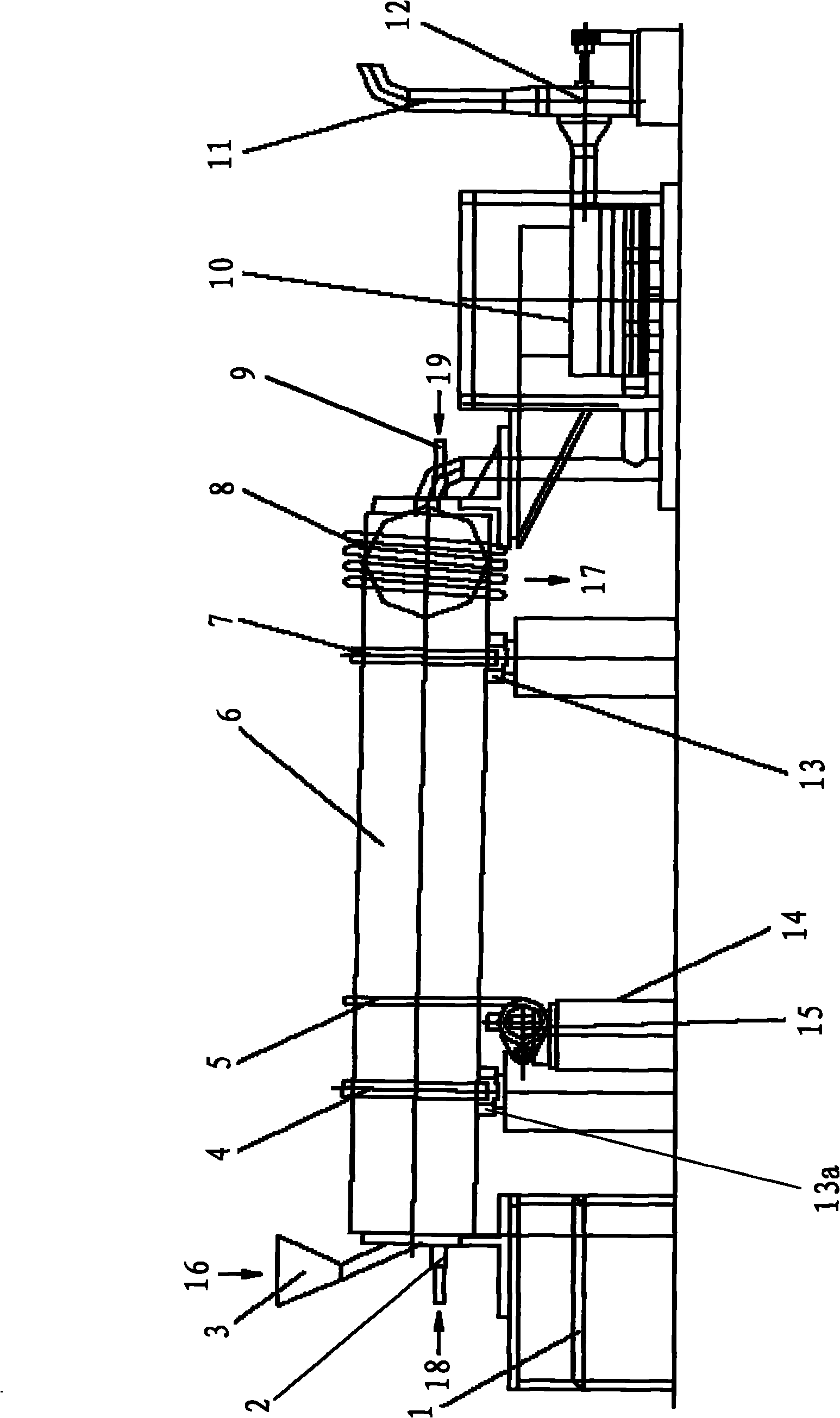

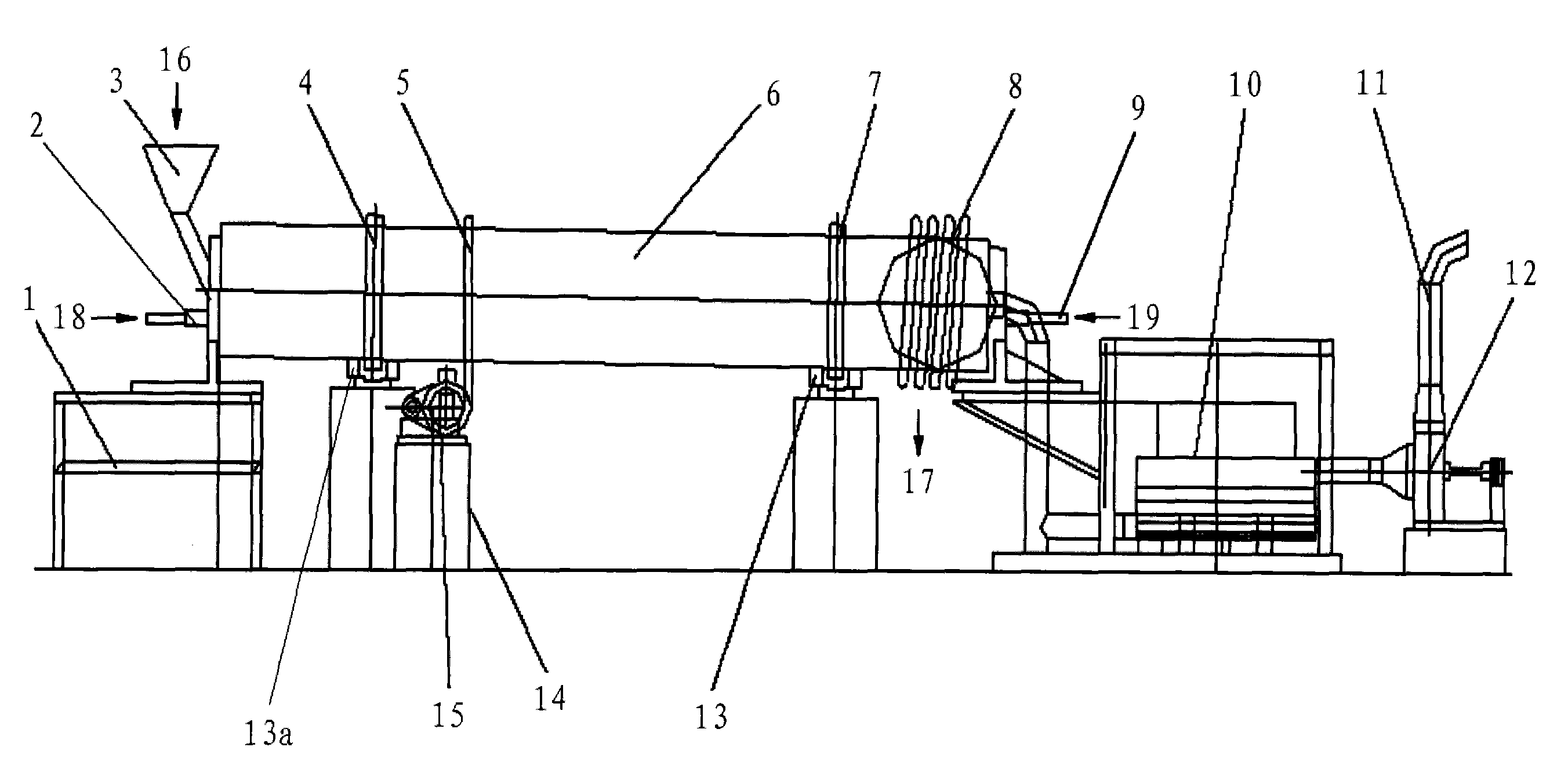

[0038] Such as figure 1 As shown, the production method of activated carbon integrated with carbonization and activation is as follows:

[0039] Raw material preparation stage

[0040] First of all, the Taixi anthracite is granulated at high speed, from the original 200 mesh (ie 0.075mm) to 320 mesh, and pre-oxidized in an oxygen-enriched environment to achieve the purpose of low-temperature carbonization, so that it has preliminary adsorption properties , iodine (I 2 ) adsorption value reaches 400mg / g, which creates conditions for subsequent activation of pore formation; secondly, solid coal tar pitch accounting for 15% by weight of raw materials is added in the coal blending process to replace the original binder coal tar to reduce production pollution and make At the same time, increase the adhesiveness and skeleton material coal tar pitch to improve the strength of the finished product; thirdly, use the dry roll forming equipment briquetting machine to press the prepared...

Embodiment 2

[0045] Such as figure 1 As shown, the activated carbon production method integrating carbonization and activation includes:

[0046] High-speed granulation of Taixi anthracite, from the original 4 mesh (ie 4.75mm) to 320 mesh, iodine (I 2 ) adsorption value reaches 200mg / g, 20% solid coal tar pitch by weight is added in the coal blending process, and the volume ratio of air-steam mixed gas 18 and 19 is 1:4. Other method steps are identical with embodiment 1.

Embodiment 3

[0048] Such as figure 1 As shown, the activated carbon production method integrating carbonization and activation includes:

[0049] High-speed granulation of Taixi anthracite, from the original 6mm to 320 mesh, iodine (I 2 ) adsorption value reaches 500mg / g, 20% solid coal tar pitch by weight is added in the coal blending process, and the volume ratio of air-steam mixed gas 18 and 19 is 1:4. Other method steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com