A preparation method of layered porous activated carbon electrode material for supercapacitor

A technology of porous activated carbon and supercapacitor, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of single structure, unfavorable popularization and use, etc., and achieves improved capacitance performance, simple and easy operation of the preparation process, and environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

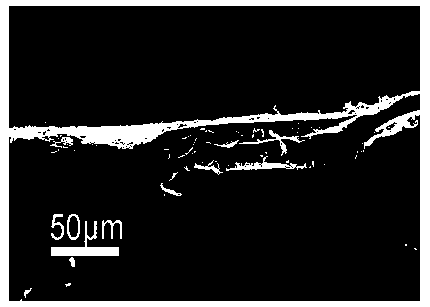

[0031] 1) Carbonization treatment of casings: Soak the casings in warm water at 60°C for 10 hours, wash and dry them, then weigh 10g casings, and weigh 10g casings by figure 1 It can be seen that the casing has an obvious layered structure.

[0032] The sausage casings were laid flat and stacked in a corundum boat, moved into a tube furnace under a nitrogen atmosphere, raised to 500°C at a heating rate of 1°C / min, and carbonized at a constant temperature for 5 hours to obtain a layered casing charcoal material.

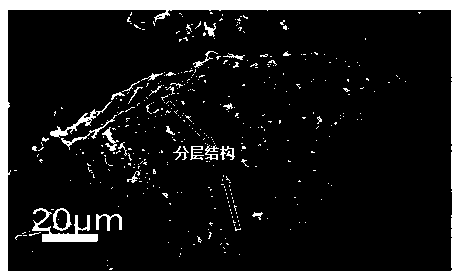

[0033] The SEM image of the above layered casing carbon material is shown in figure 2 shown by figure 2 It can be seen that the pre-carbonized casing material is irregular block with obvious layered structure, and the surface of the block sample is relatively smooth without obvious holes and channels.

[0034] 2) Weigh 12g of potassium hydroxide and dissolve it in an appropriate amount of deionized water to form lye.

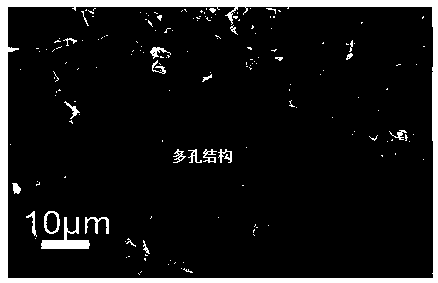

[0035] Weigh 3g of sausage-coated charcoal m...

Embodiment 2

[0043] 1) Carbonization treatment of casings: Soak the casings in warm water at 90°C for 5 hours, wash and dry them, weigh 10g of casings, lay them flat and stack them in a corundum boat, move them into a tube furnace under a nitrogen atmosphere, and heat up at a rate of 5°C / min The temperature was raised to 800°C, and carbonized at a constant temperature for 2 hours to obtain a layered casing carbon material.

[0044] 2) Weigh 15g of potassium hydroxide and dissolve it in an appropriate amount of deionized water to form lye.

[0045] Weigh 3g of sausage-coated charcoal material and add it to the lye, stir evenly with a glass rod, ultrasonicate for 30 minutes, seal with plastic wrap, soak for 5 hours at room temperature, and then dry in an oven to obtain a mixture.

[0046]3) Move the mixture into a nickel crucible, move it into a tube furnace under a nitrogen atmosphere, raise the temperature to 900°C at a heating rate of 10°C / min, activate at a constant temperature for 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com