Porous matrix-loaded multilayer electrode electrochemical wastewater treatment device as well as preparation method and use method thereof

A multi-layer electrode, porous matrix technology, applied in water treatment parameter control, chemical instruments and methods, water/sewage treatment equipment and other directions, can solve the problems of high energy consumption and poor electrode treatment effect, achieve energy saving, Solve the poor processing effect and increase the effect of removing types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

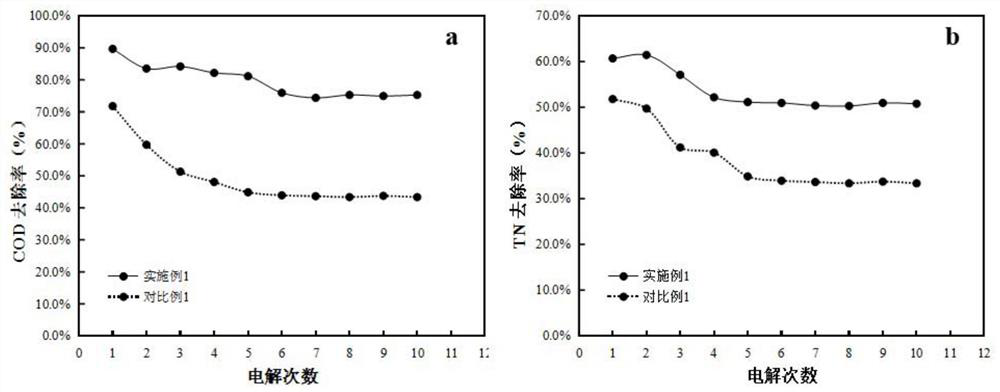

Embodiment 1

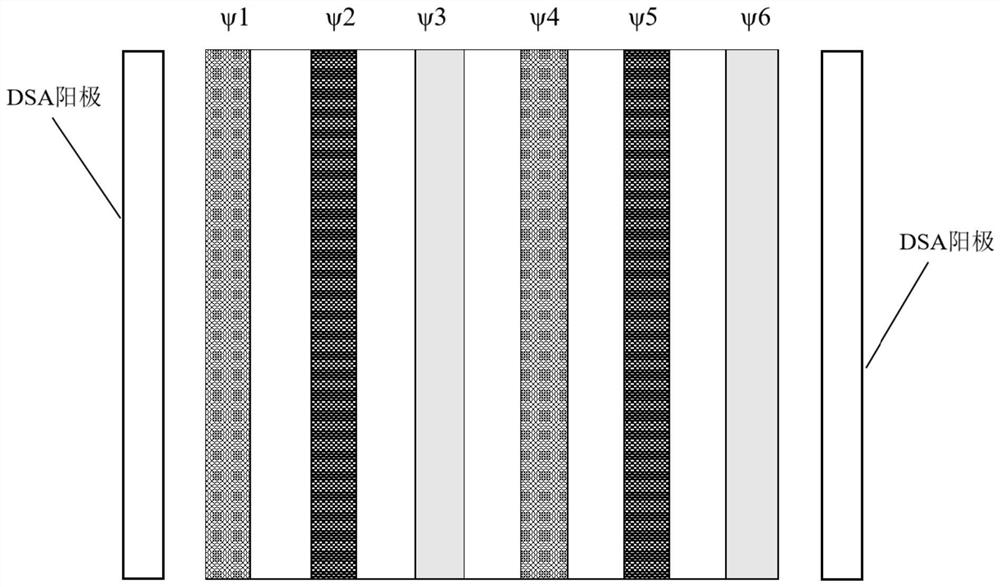

[0053] The multi-layer electrode electrochemical wastewater treatment device supported by a porous substrate of the present invention is applied in the technical field of electrochemical water treatment, and is made of high-purity graphite felt after modification and loading. When the present invention is used to treat wastewater, the pH of domestic sewage influent is 4-14, and the pH of chemical wastewater influent is 2-14. The active substances produced by electrolysis are different under different pH environments, and better treatment can be achieved by adjusting the pH for different sewage types. Effect. The invention comprises a cathode unit and at least two anodes, and the anodes are arranged on opposite sides of the cathode unit to improve the utilization rate of the cathode. The cathode unit includes at least two cathodes, and the arrangement of the cathodes is sequentially arranged from one anode to the other.

[0054] The cathode material is graphite felt with a thi...

Embodiment 2

[0089] The basic content of this embodiment is the same as that of Embodiment 1, and the difference is that in this embodiment, 6 cathodes are arranged in total, and the commercial DSA electrode is an anode, and the specific preparation steps of the cathode are:

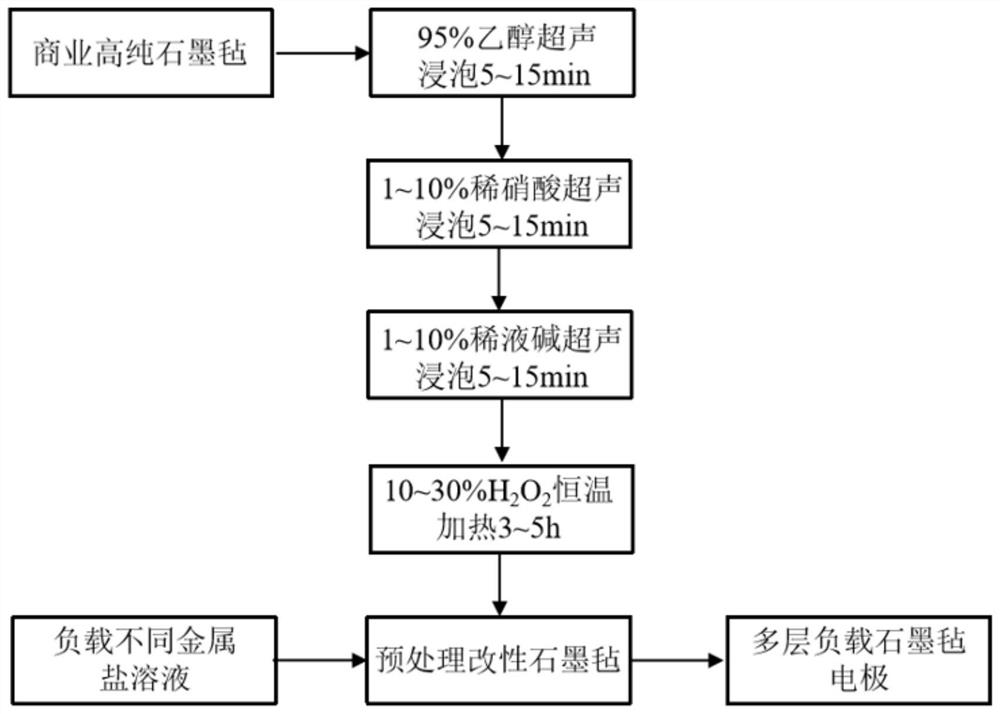

[0090] Step 1: Put the graphite felt in 95% absolute ethanol, 5% dilute acid and 5% dilute alkali for ultrasonic cleaning. The cleaning time of each cleaning step is 10min. ℃ drying; the acid used is nitric acid, and the alkali used is sodium hydroxide;

[0091] Step 2: Submerge the cleaned and dried graphite felt to 20% H 2 o 2 solution, heated at a constant temperature of 50°C for 4 hours; after the modification was completed, it was washed with deionized water and dried at 60°C to obtain the modified graphite felt;

[0092]Step 3: use the modified graphite felt to be respectively loaded with salt solutions of cobalt nitrate, copper nitrate, tin nitrate, antimony nitrate, ruthenium nitrate, and cerium nitrate to ...

Embodiment 3

[0095] The basic content of this embodiment is the same as that of Embodiment 1, and the difference is that in this embodiment, 6 cathodes are arranged in total, and the commercial DSA electrode is an anode, and the specific preparation steps of the cathode are:

[0096] Step 1: Put the graphite felt in 95% absolute ethanol, 10% dilute acid and 10% dilute alkali for ultrasonic cleaning. The cleaning time of each cleaning step is 15min. ℃ drying; the acid used is nitric acid, and the alkali used is sodium hydroxide;

[0097] Step 2: Submerge the cleaned and dried graphite felt to 30% H 2 o 2 solution, heated at a constant temperature of 55°C for 5 hours; after the modification was completed, it was washed with deionized water and dried at 100°C to obtain a modified graphite felt;

[0098] Step 3: the modified graphite felt is respectively loaded with salt solutions of tin chloride, antimony chloride, cobalt chloride, cupric chloride, cerium chloride, and ruthenium chloride to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com