Method for preparing metal-based gradient coating with enhanced laser-cladding ceramic nano-particles

A technology of nano-ceramic particles and laser cladding, which is applied in the coating process of metal materials, metal layered products, coatings, etc., to achieve the effect of solving high brittleness, easy agglomeration, and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

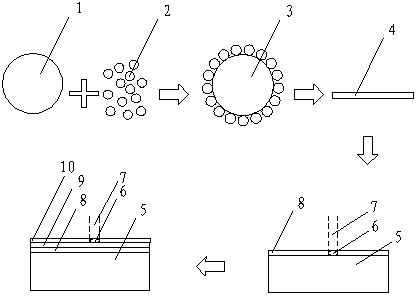

[0034] see figure 1 A method for preparing a metal-based gradient coating reinforced by laser cladding nano-ceramic particles of the present invention comprises the following steps:

[0035] First of all, several groups of mixed powders of micron metal powder 1 and nano-ceramic particles 2 with a certain ratio are prepared by mechanical composite method (high-energy ball milling) into corresponding coated composite powders 3 with evenly dispersed nanoparticles. In the mixed powder of the proportioned micron metal powder 1 and nano-ceramic particles 2, the content of nano-ceramic particles 2 gradually increases;

[0036] Secondly, the laser cladding sheet 4 is pressed by the molding method, that is, the prepared coated composite powder 3 is pressed into a cladding sheet 4 of a certain thickness in a mold by using a press or a tablet machine, so as to realize the green pre-treatment of the cladding layer. set;

[0037] Finally, the method of multi-layer laser cladding is used ...

Embodiment 1

[0039] Laser multi-layer cladding nano-Al on the surface of TiAl-based intermetallic compound alloy (TiAl alloy for short) substrate surface 2 o 3 MCrAlY-based gradient high-temperature oxidation-resistant coating reinforced by ceramic particles, M=Ni and Co, the specific steps are:

[0040] ①By controlling the mass ratio of balls to powder, the speed of the ball mill and the milling time, the nano-Al 2 o 3 Ceramic particles (average particle size 20nm) and MCrAlY alloy powder (Beijing General Research Institute of Mining and Metallurgy Metal Materials Institute, brand KF-113A, size distribution range 45~105μm) are mechanically composited into nano-Al on a high-energy ball mill. 2 o 3 Coated composite particles with evenly dispersed ceramic particles and coated around the micron MCrAlY powder;

[0041] ②According to the characteristics of small composite powder particles and large powder surface area, use the electrostatic force generated by friction during the molding pro...

Embodiment 2

[0044] Laser multi-layer cladding nano-Cr on the surface of TiAl alloy substrate 2 C 3 The NiCr-based gradient high-temperature wear-resistant coating reinforced by ceramic particles, its specific steps are similar to those of Example 1:

[0045] ① The mass ratio of 1:10, 1:5, 1:2 nano-Cr 2 C 3 Ceramic particles (average particle size 30nm) and NiCr alloy powder (Metal Materials Institute of Beijing General Research Institute of Mining and Metallurgy, brand KF-305, size distribution range 45~105μm) are mechanically compounded on a high-energy ball mill to form nano-Cr 2 C 3 Coated composite particles with evenly dispersed ceramic particles and coated around micron NiCr powder;

[0046] ②The micro-nano composite particles with different proportions are respectively pressed into a laser cladding sheet (size 25mm×8mm, thickness about 0.2mm) that is firmly bonded together by the molding method on the press;

[0047] ③Before laser cladding, roughen and clean the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com