Titanium-based composite material with two-stage net structures and preparation method of titanium-based composite material

A technology of titanium-based composite material and network structure, which is applied in the field of network-structured titanium-based composite material and its preparation, can solve problems such as limitation of reinforcement effect, and achieve the advantages of simple preparation method, strong controllability, and improvement of room temperature modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

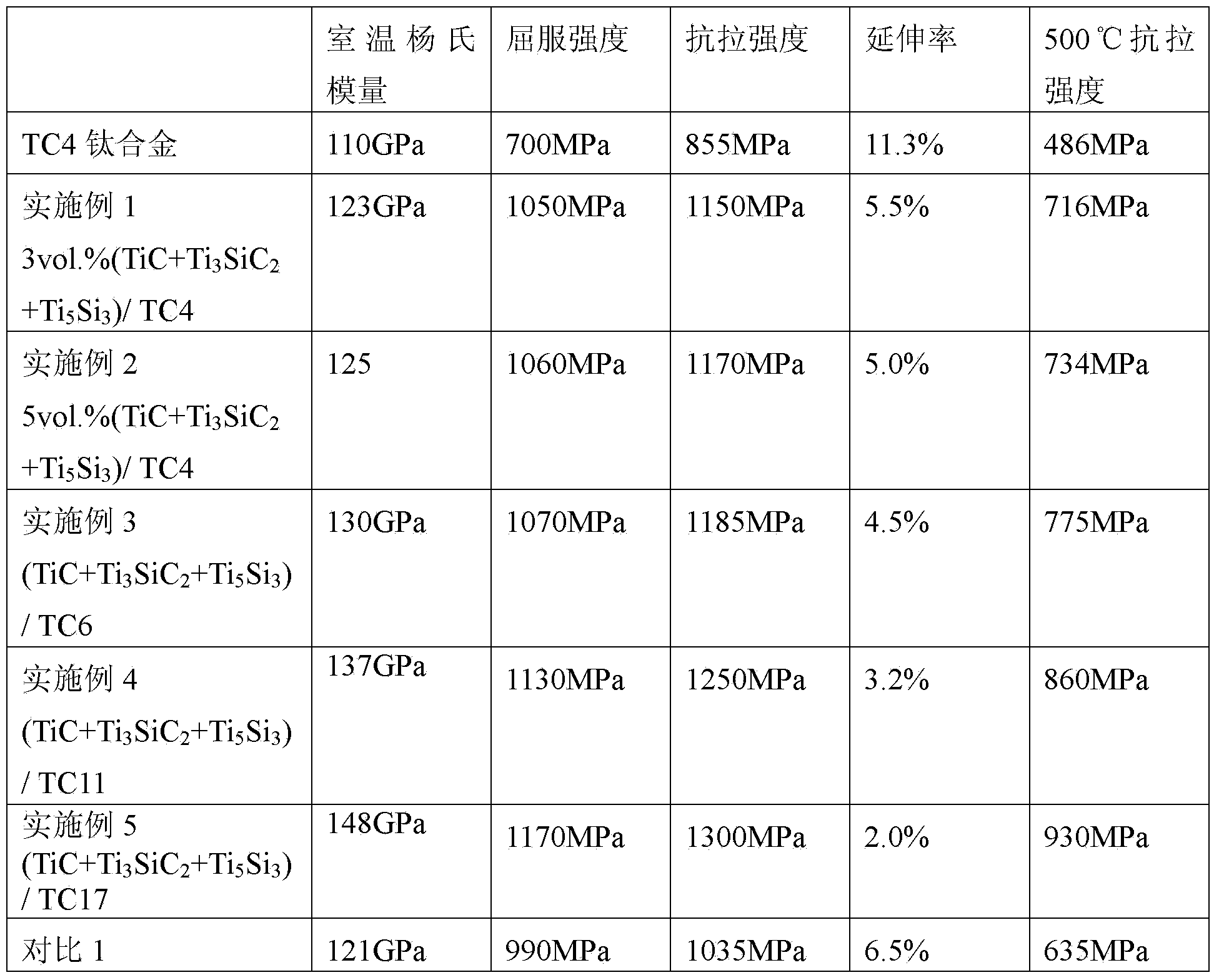

[0014] Specific implementation mode 1: In this embodiment, the two-stage network structure titanium-based composite material uses SiC as the reinforcement material, and uses the α+β dual-phase titanium alloy as the matrix; and has a two-stage network structure, and the first-level network structure is located Boundary, by TiC+Ti 3 SiC 2 Hybrid reinforcement is formed; the secondary network structure is located in the intragranular β phase, composed of Ti 5 Si 3 Ceramic phase composition.

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the particle size of SiC is <1 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the α+β duplex titanium alloy is TC4, TC6, TC11 or TC17. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com