A kind of high-strength chitin composite hydrogel material and its preparation method and application

A technology of compounding hydrogel and chitin, which is applied in pharmaceutical formulations, prostheses, drug delivery, etc., can solve problems such as complex methods, and achieve the effects of simple operation, low cost, and easy purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: Preparation of high-strength chitin composite hydrogel material

[0053] Step 1: Soak chitin powder in 0.5 mol / L NaOH solution at room temperature and stir for 24 hours, then filter and wash with water for several times until the washing liquid is neutral. Then, soak the chitin powder in 0.01mol / L NaClO at 90°C 2 Stir in the solution (adjust the pH to 4 with acetic acid) for 4 h, then filter and wash with water for several times until the washing liquid is neutral. Finally, it is freeze-dried and ground to obtain purified chitin powder. At -25°C, according to the concentration of 2wt%, chitin powder was dissolved in alkaline ionic liquid (16wt% KOH, 7wt% urea), stirred for 4 hours, transferred to 4°C for 30h, and then placed at 0°C Centrifuge for 15 minutes to remove air bubbles to obtain a chitin solution.

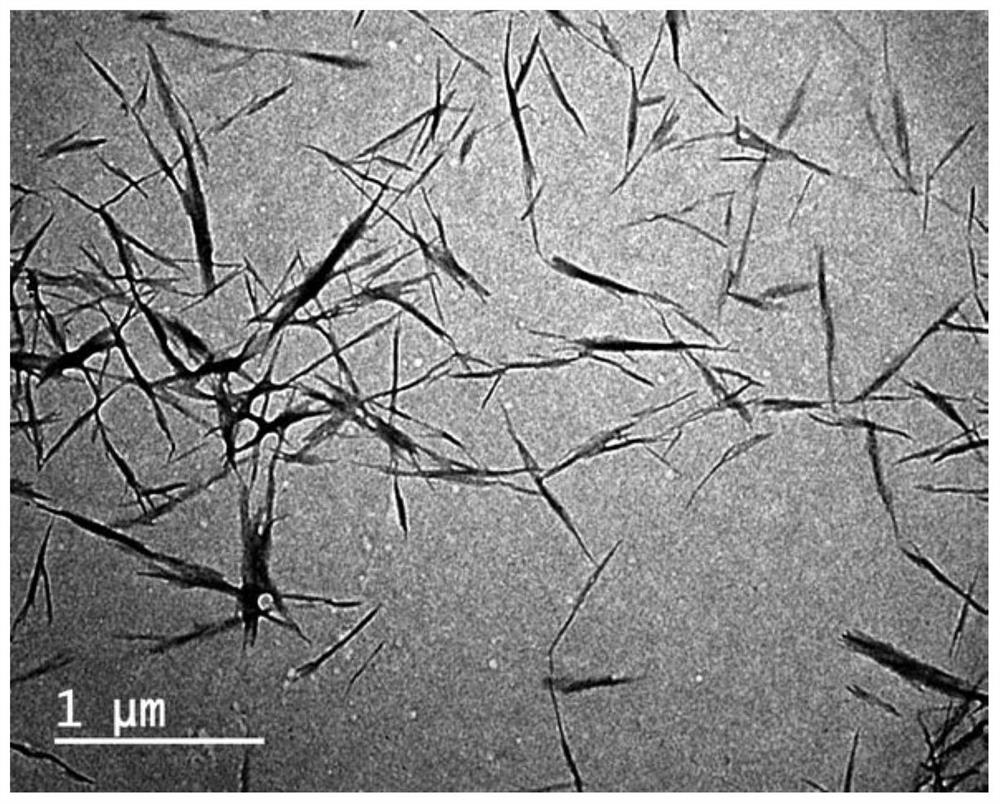

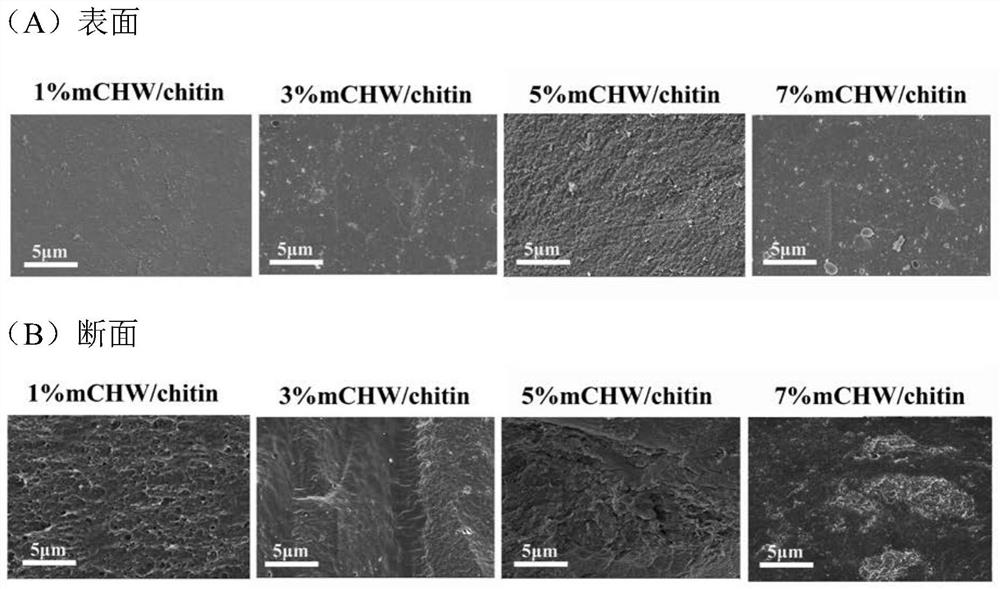

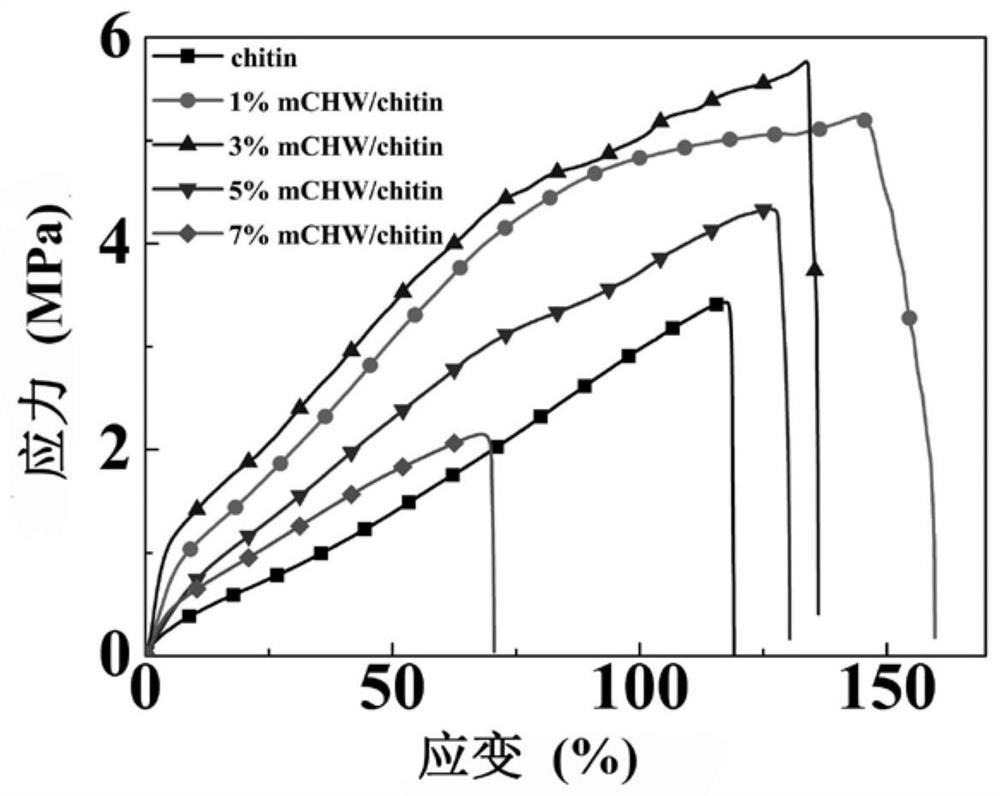

[0054] Step 2: Melt 80 parts by mass of solid maleic anhydride at 70°C, then add 4 parts by mass of chitin powder, and 2 The reaction was stirred...

Embodiment 2

[0057] Embodiment 2: Preparation of high-strength chitin composite hydrogel material

[0058] Step 1: Soak chitin powder in 1 mol / L NaOH solution at room temperature and stir for 20 hours, then filter and wash with water for several times until the washing liquid is neutral. Then, soak the chitin powder in 0.05mol / L NaClO at 80°C 2 Stir in the solution (adjust the pH to 4 with acetic acid) for 5 h, then filter and wash with water for several times until the washing liquid is neutral. Finally, it is freeze-dried and ground to obtain purified chitin powder. At -30°C, according to the concentration of 5wt%, chitin powder was dissolved in alkaline ionic liquid (18wt% KOH, 4wt% urea), stirred for 3 hours, transferred to 6°C for 20h, and then placed at 0°C Centrifuge for 15 minutes to remove air bubbles to obtain a chitin solution.

[0059] Step 2: Melt 320 parts by mass of solid maleic anhydride at 60°C, then add 16 parts by mass of chitin powder, and 2 The reaction was stirred...

Embodiment 3

[0062] Embodiment 3: Preparation of high-strength chitin composite hydrogel

[0063] Step 1: Soak chitin powder in 2mol / L NaOH solution at room temperature and stir for 15 hours, then filter and wash with water for several times until the washing liquid is neutral. Then, soak the chitin powder in 0.25mol / L NaClO at 70°C 2 Stir in the solution (adjust the pH to 4 with acetic acid) for 3 h, then filter and wash with water for several times until the washing liquid is neutral. Finally, it is freeze-dried and ground to obtain purified chitin powder. At -35°C, according to the concentration of 8wt%, chitin powder was dissolved in alkaline ionic liquid (20wt% KOH, 5wt% urea), stirred for 2h, then transferred to 8°C for 12h, and then placed at 0°C Centrifuge for 15 minutes to remove air bubbles to obtain a chitin solution.

[0064] Step 2: Melt 150 parts by mass of solid maleic anhydride at 80°C, then add 7.5 parts by mass of chitin powder, and 2 The reaction was stirred at 100° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com