A high-strength and high-heat-resistant carbon nano-aluminum matrix composite material and its preparation method

An aluminum-based composite material and carbon nanotechnology, which is applied in the field of high-strength and high-heat-resistant carbon nano-aluminum-based composite materials and its preparation, can solve problems such as insufficient heat resistance and low alloy strength, achieve high production efficiency, reduce agglomeration, and avoid The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Alloy composition: based on 100% alloy mass, reduced graphene oxide 0.09%, Zr 0.30%, Fe 0.008%, Si 0.038%, Ti 0.010%, and the balance is Al.

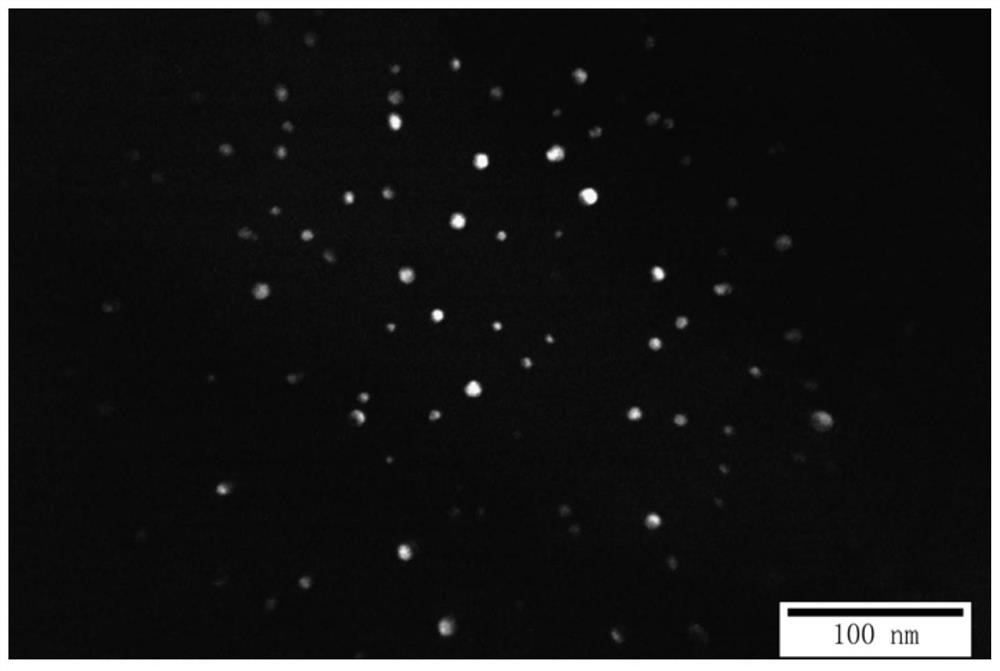

[0032]The preparation process and proportion of reduced graphene oxide@alumina are as follows: prepare KH-550 silane coupling agent solution, the volume ratio of ethanol: water is 0.5:14, and the content of KH-550 in the solution is 1.2vol.% volume fraction , statically dissolved for 2 hours; add no more than 5 layers of graphene oxide with an average sheet diameter of 10 microns in the solution, so that the concentration of graphene oxide is 3.0g / L, then add alumina powder and ultrasonically treat for 60min, the nano-alumina powder The diameter is 30nm. After the mixed solution obtained is vacuum freeze-dried, graphene oxide reduction sintering is carried out. The sintering temperature is 1000°C, and the time is 6h. The reduced graphene oxide@alumina composite powder is obtained, wherein the quality of alumina is reduction oxidat...

Embodiment 2

[0035] Alloy composition: based on 100% alloy mass, reduced graphene oxide 0.01%, Zr 0.1%, Ti 0.010%, Fe 0.071%, Si 0.035%, each of the remaining elements ≤ 0.01%, and the balance is Al.

[0036] The preparation process and proportion of pre-synthesized reduced graphene oxide@alumina are as follows: prepare KH-550 silane coupling agent solution, the volume ratio of ethanol: water is 1:9, and the content of KH-550 in the solution is 1.5vol.%. Static dissolving for 6 hours; add no more than 3 layers of graphene oxide with an average sheet diameter of 15 microns to the solution to make the concentration of graphene oxide 0.5g / L, then add alumina powder and ultrasonically treat for 100min, the particle size of nano-alumina powder 5nm, the obtained mixed solution was subjected to vacuum freeze-drying, then reduced sintering of graphene oxide, the sintering temperature was 1500°C, and the time was 2h, and the reduced graphene oxide@alumina composite powder was obtained, wherein the m...

Embodiment 3

[0039] Alloy composition: based on 100% alloy mass, reduced graphene oxide 0.05%, Zr 0.3%, Ti 0.010%, Fe 0.069%, Si 0.034%, each of the remaining elements ≤ 0.01%, and the balance is Al.

[0040] The preparation process and proportion of pre-synthesized reduced graphene oxide@alumina are as follows: prepare KH-550 silane coupling agent solution, the volume ratio of ethanol: water is 0.5:9, and the content of KH-550 in the solution is 1.0vol.%. Volume fraction, statically dissolved for 4 hours; add no more than 3 layers of graphene oxide with an average sheet diameter of 20 microns in the solution to make the graphene oxide concentration 2g / L, then add alumina powder and ultrasonically treat for 80min, nano-alumina powder The particle size is 100nm. After vacuum freeze-drying, the obtained mixed solution is subjected to reduction and sintering of graphene oxide at a sintering temperature of 1250°C for 4 hours to obtain a reduced graphene oxide@alumina composite powder, in which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com