Preparation method of phenyl silsesquioxane/oxidized graphene/polyimide three-phase compound film

A phenyl sesqui, composite film technology, applied in the field of insulating materials, can solve problems such as reducing the dielectric constant, and achieve the effects of excellent dielectric properties, good mechanical properties, and good thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

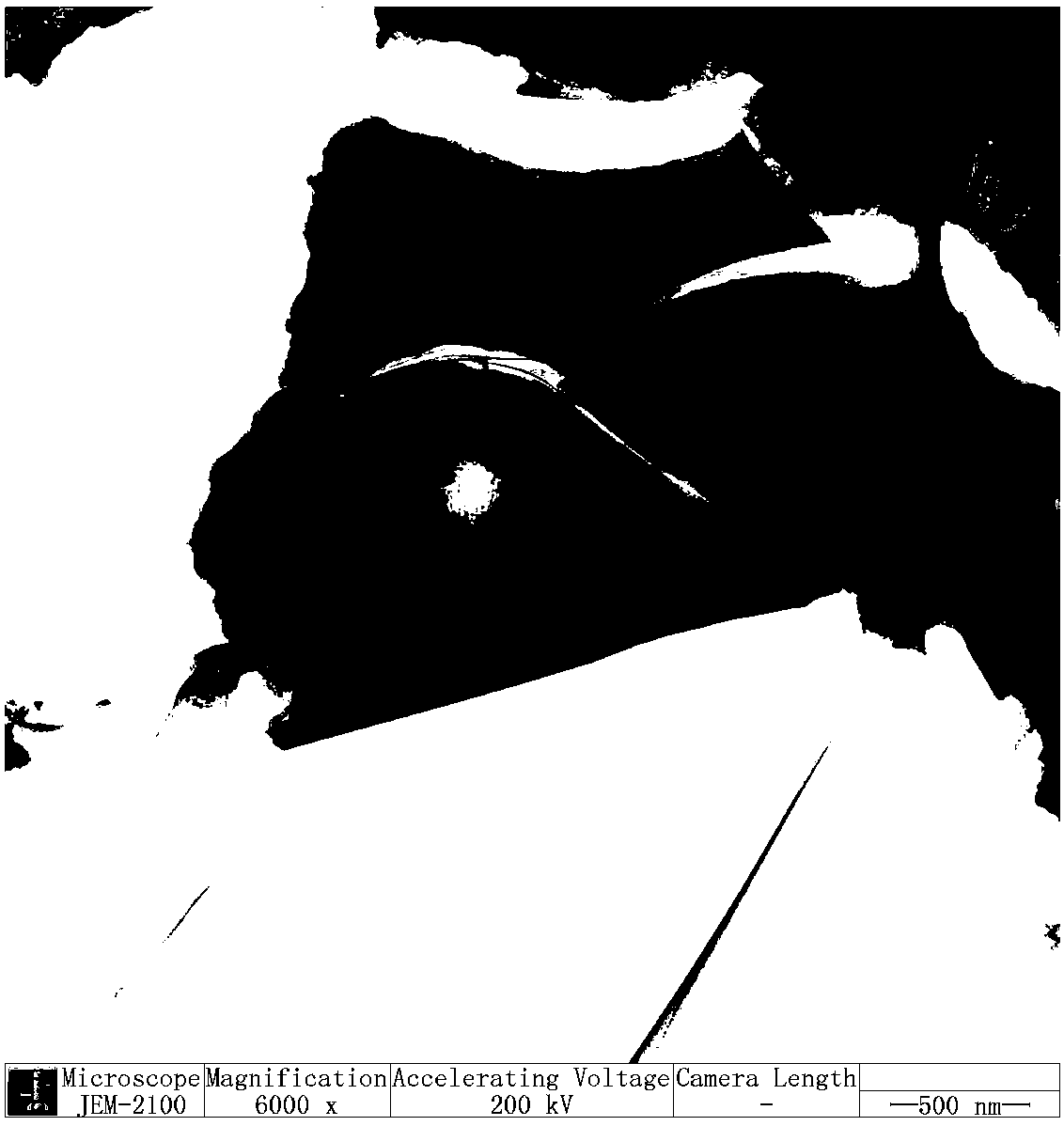

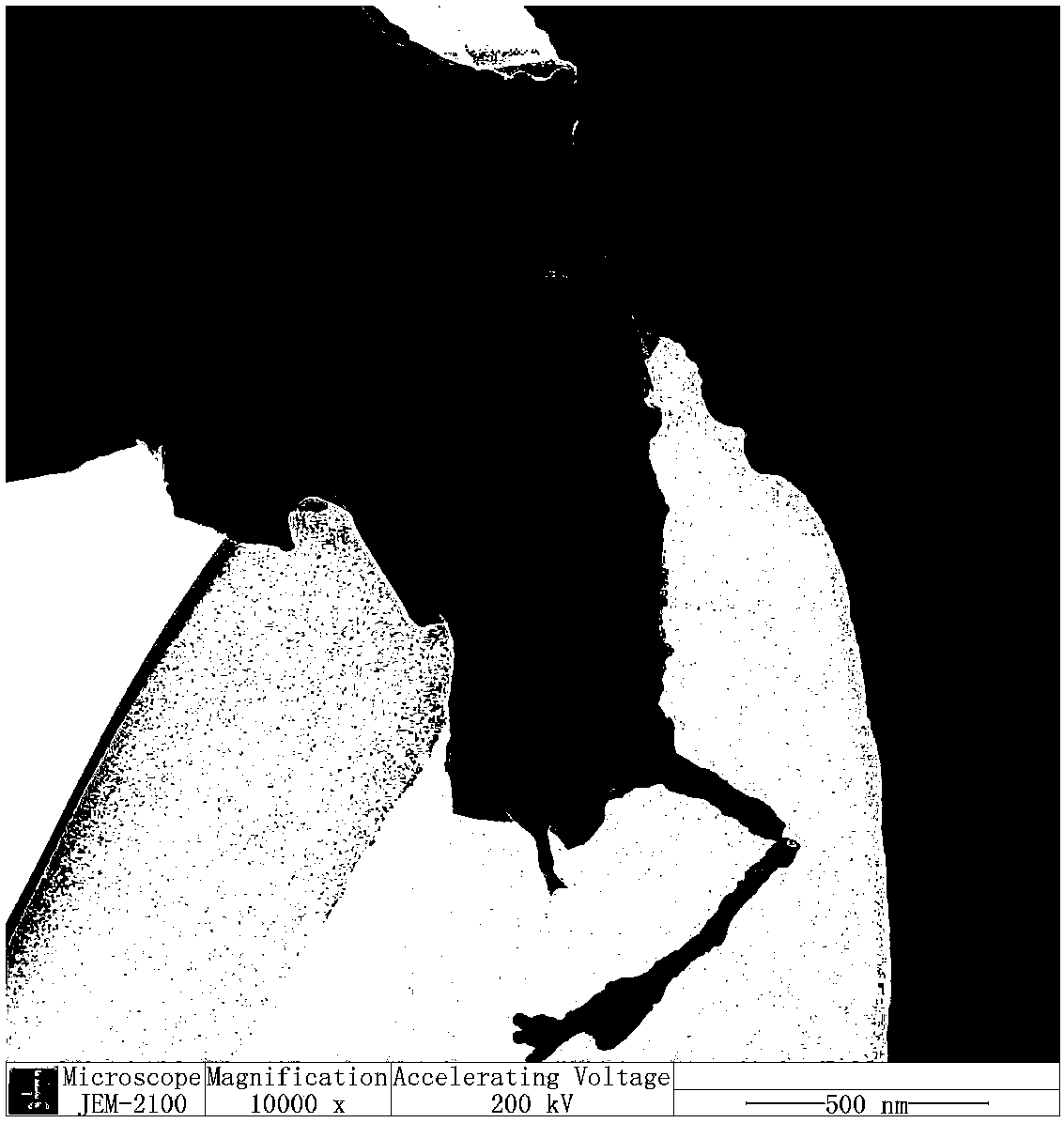

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: the preparation method of a kind of phenylsilsesquioxane / graphene oxide / polyimide three-phase composite film of this embodiment is to carry out according to the following steps:

[0023]1. Under the condition of ice-water bath, use mixed acid solution to dissolve the expanded graphite, mechanically stir until the expanded graphite is completely dissolved, then add potassium permanganate to it, mechanically stir until the potassium permanganate is completely dissolved, continue stirring for 1-2 hours, and then transfer to Keep warm in a water bath with a temperature of 35°C for 1 to 2 hours, then raise the temperature of the water bath from 35°C to 98°C, and add deionized water to it at a constant rate using a separatory funnel during the heating process until the temperature reaches 98°C. After incubating at 98°C for 1-2 hours, add 30% hydrogen peroxide solution until the solution turns bright yellow; dilute the bright yellow solution, filter the...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of the mass of expanded graphite described in step 1 to the mixed acid solution is 1g:100mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass ratio of expanded graphite and potassium permanganate described in step one is 1:6. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com