High-strength, high-conductivity and high-heat-resistance aluminum-base composite for tension joint splice and preparing method

An aluminum-based composite material and a technology for connecting metal fittings, which are applied in the field of high-strength, high-conductivity, and high-heat-resistance aluminum-based composite materials for connecting metal fittings and their preparation, can solve the problems of insufficient heat resistance, low alloy strength, etc., and achieve high production efficiency and agglomeration. Reduced, chemically stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

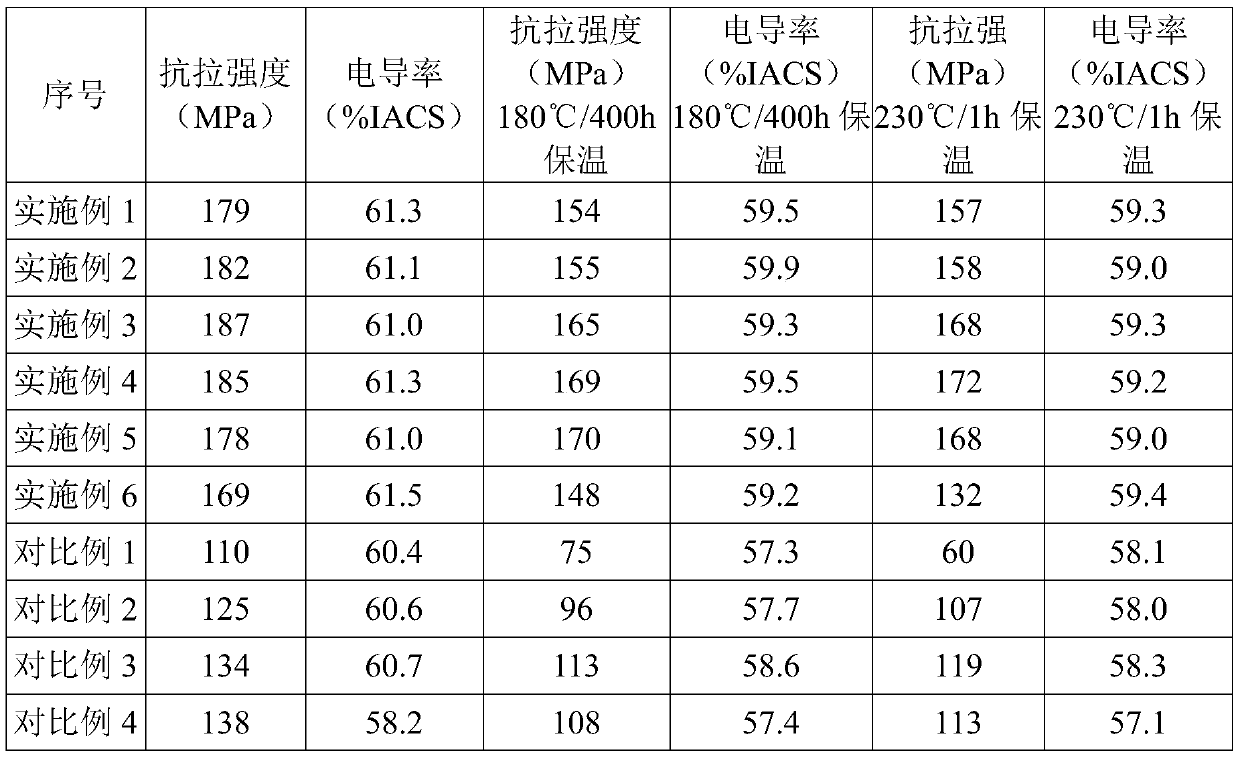

Examples

Embodiment 1

[0029] Alloy composition: Based on the alloy mass as 100%, reduced graphene oxide 0.09%, Zr 0.2%, Er 0.1%, Ti 0.001%, Fe 0.065%, Si ≤ 0.043, each of the remaining elements ≤ 0.01%, the balance is Al .

[0030] The preparation process and proportion of reduced graphene oxide@copper are as follows: prepare KH-550 silane coupling agent solution, the volume ratio of alcohol to water is 10:1, the content of KH-550 in the solution is 0.9vol.%, and it is dissolved for 4 hours; Add graphene oxide to the solution to make the graphene oxide concentration 0.1g / L, then add nano-copper powder for ultrasonic treatment for 60min, the particle size of nano-copper powder is 5nm. Hydrogen reduction sintering, the sintering temperature is 1200°C, and the time is 5 hours, and the reduced graphene oxide@copper composite powder is obtained.

[0031] Clean the furnace before starting the furnace. If alloys other than 1 series have been produced before, it is necessary to arrange for furnace cleaning ...

Embodiment 2

[0033] Alloy composition: Based on the alloy mass as 100%, reduced graphene oxide 0.01%, Zr 0.2%, Er 0.2%, Ti 0.008%, Fe 0.070%, Si 0.045%, the remaining elements are ≤0.01% each, and the balance is Al .

[0034] The preparation process and proportion of pre-synthesized reduced graphene oxide@copper are as follows: prepare KH-550 silane coupling agent solution, the volume ratio of alcohol and water is 1:12, the content of KH-550 in the solution is 0.1vol.%, and it is dissolved for 4 hours Add graphene oxide in the solution so that the graphene oxide concentration is 0.5g / L, then add nano-copper powder for ultrasonic treatment for 30min, the particle size of nano-copper powder is 30nm, and the mixed solution obtained is oxidized after vacuum freeze-drying Graphene hydrogen reduction sintering, sintering temperature 1200 ° C, time 1 hour, obtained reduced graphene oxide@copper composite powder.

[0035] Clean the furnace before starting the furnace. If alloys other than 1 serie...

Embodiment 3

[0037] Alloy composition: Based on the alloy mass as 100%, reduced graphene oxide 0.05%, Zr 0.1%, Er 0.1%, Ti 0.009%, Fe 0.068%, Si 0.043%, each of the remaining elements ≤ 0.01%, the balance is Al .

[0038] The preparation process and proportion of pre-synthesized reduced graphene oxide@copper are as follows: prepare KH-550 silane coupling agent solution, the volume ratio of alcohol to water is 7:5, the content of KH-550 in the solution is 0.5vol.%, and it is dissolved for 6 hours Add graphene oxide in the solution so that the graphene oxide concentration is 0.5g / L, then add nano-copper powder for ultrasonic treatment for 40min, the particle size of nano-copper powder is 20nm, and the mixed solution obtained is oxidized after vacuum freeze-drying Graphene hydrogen reduction sintering, sintering temperature 1000 ° C, time 3 hours, to obtain reduced graphene oxide@copper composite powder.

[0039] Clean the furnace before starting the furnace. If alloys other than 1 series ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com