TPL preheating scale prevention process in wastewater industry

A process and industry technology, applied in the field of TPL preheating and anti-scaling process in the wastewater industry, can solve the problems of high investment, high operating cost, high energy consumption, etc., and achieve the effect of reducing coal consumption, increasing production time, and reducing equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

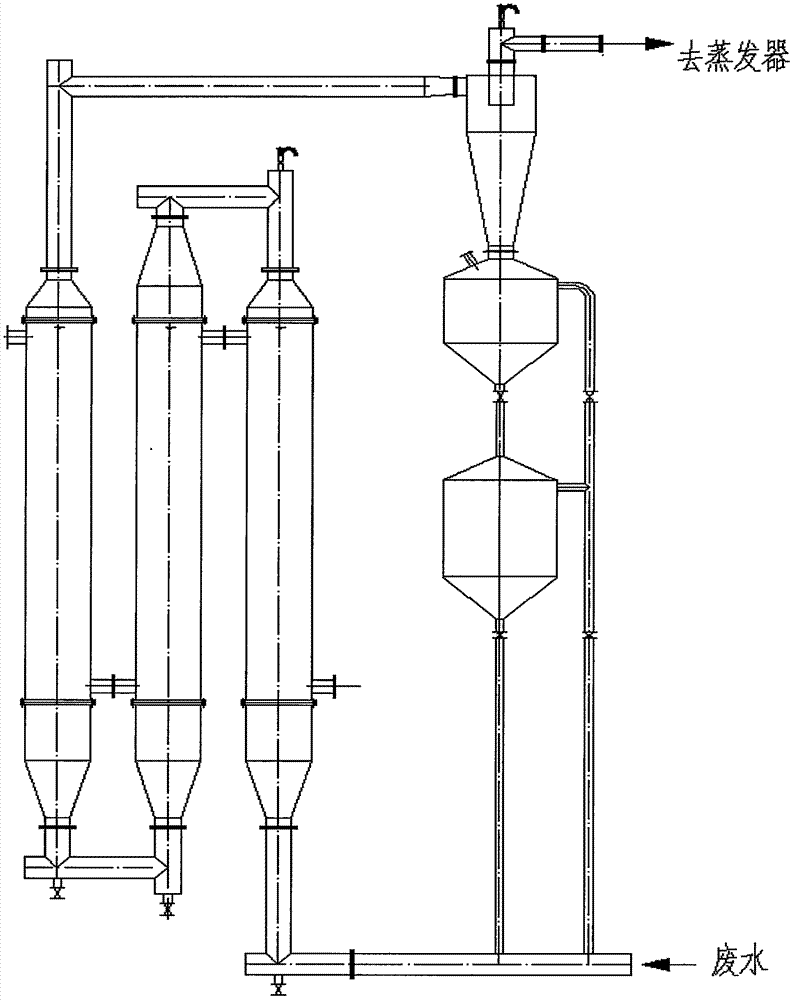

[0012] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0013] The TPL preheating and anti-scaling process in the wastewater industry according to the present invention is based on the following principle: combining evaporative boiling heat transfer and circulating fluidized bed technology to form a multi-phase consisting of solvent vapor, solution, and inert solid particles in the evaporation system circulation system. Due to the chaotic movement of fluidized solid particles, the flow boundary layer at the heat transfer wall of the heating chamber is destroyed, and the induction period of fouling is prolonged, thereby achieving the purpose of prolonging the heat transfer in the tube and online prevention and descaling.

[0014] In the TPL preheating and anti-scaling pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com