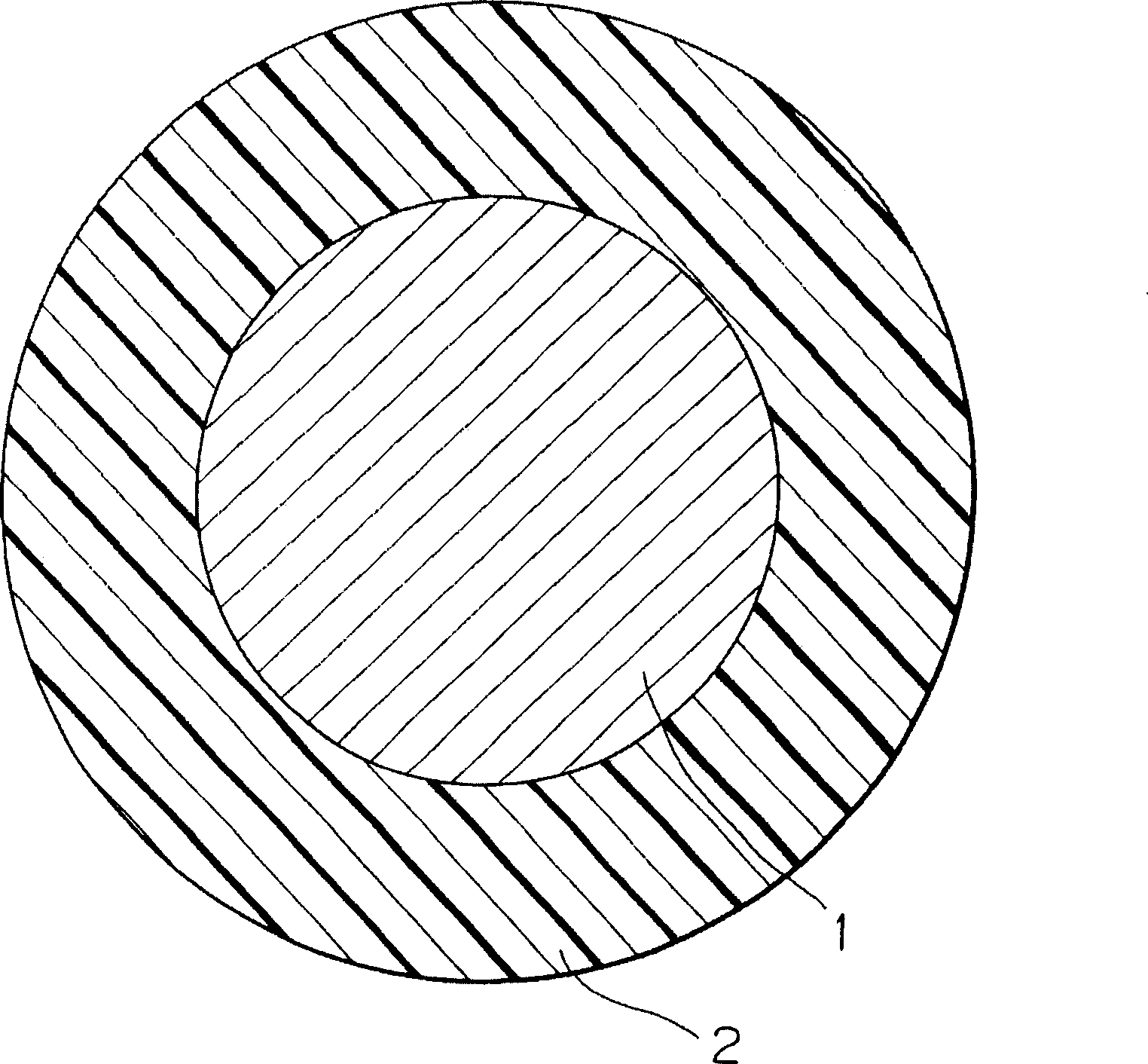

Rotating body for image forming apparatus

A technology of imaging equipment and rotating body, which is applied in the field of rotating body, can solve the problems of high cost of facilities, pollution of surrounding air, high cost of facilities, etc., and achieve cost-effective, life-span reduction, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Tetramethoxysilane is introduced in a flame formed by oxygen and liquefied natural gas. The surface of the tape prepared in Comparative Example 1 was heated with a flame for a short period of time to provide the tape of Example 1.

[0041] Prepare samples

[0042] Each sample was derived from the tapes of Comparative Examples 1, 2 and Example 1, respectively. Each sample was heated together with silicone rubber (DOWCORNING CORP., DY35-796) at a temperature of 130° C. for 25 minutes to provide three kinds of belts each covered with a silicone rubber layer having a thickness of 1 mm and an ASKER-C hardness of 24 degrees.

[0043] Adhesion test

[0044] For these three samples, a crosscut test was performed to evaluate the adhesion. Specifically, 11 horizontal cuts and 11 vertical cuts were made with a knife in a 1 cm wide by 1 cm long square of each cover layer, noting that the distance between the parallel cuts was 1 mm. Each sample had approximately 100 transected t...

Embodiment 2

[0054] Example 2 was prepared as described in Example 1, substituting the aluminum mandrel from Comparative Example 3 for the polyimide tape.

[0055] Prepare samples

[0056] Each sample was derived from the mandrels of Comparative Examples 3, 4 and 5 and Example 2, respectively. Each sample was heated together with silicone rubber (DOW CORNING CORP., DY35-796) at a temperature of 130° C. for 25 minutes to provide four kinds of cores each covered with a silicone rubber layer having a thickness of 2 mm and an ASKER-C hardness of 24 degrees axis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com