Method for processing bauxite rich in alumina monohydrate

a technology of alumina monohydrate and bauxite, which is applied in the field of processing bauxite rich in alumina monohydrate, can solve the problems of difficult industrialization application, developed liquor supersaturation mode, and difficult to exploit on an industrial scale, and achieves the effects of reducing viscosity, facilitating mud settlement, and increasing alumina supersaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples of application

[0045] In examples 1 (according to the prior art), 2 and 3 (according to the invention), a first monohydrate bauxite (diaspore) was digested according to an European-type Bayer process. In example 4, a monohydrate Australian bauxite (boehmite) was digested according to an American-type Bayer process.

[0046] The dry ponderal composition of the first bauxite is as follows:

1 element % in weight Al.sub.2O.sub.3 56.77 Fe.sub.2O.sub.3 21.58 total SiO2 2.63 TiO2 2.69 Ignition loss 16.33 and various

example 1

[0047] According to the prior art, a 100 ton batch of said bauxite was digested at 260.degree. C. for 1 hour with a digestion liquor concentrated at

[0048] 210 g Na.sub.2O / l.

[0049] After flash, cooling, dilution and settling, we obtained the following results:

[0050] Liquor before crystallization

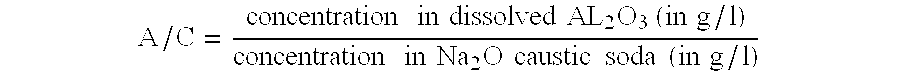

[0051] A / C: 1.15

[0052] Caustic concentration: 146 g Na.sub.2O / l

[0053] Liquor after crystallization

[0054] A / C: 0.58

[0055] Global digestion yield: 90.6% extracted alumina / total alumina

[0056] Productivity at crystallization: 83 kg Al.sub.2O.sub.3 / m.sup.3

[0057] Energy necessary for the digestion of 1 kg of alumina: 3.55 MJ

example 2

[0058] Another 100 ton batch of the same bauxite was digested according to a first mode of the invention:

[0059] Digestion at 260.degree. C. for 1 hour with a digestion liquor concentrated at 210 g Na.sub.2O / l.

[0060] Cooling to 160.degree. C.

[0061] The slurry being maintained shaken, 9.2 tons of an African bauxite rich in trihydrate (85%) was injected in slurry form, said bauxite having previously been ground in the presence of an aliquot of the digestion liquor.

[0062] The trihydrate bauxite has the following ponderal composition:

2 element % in weight Al.sub.2O.sub.3 56.5 Fe.sub.2O.sub.3 4.8 total SiO2 1.4 TiO2 3.7 Ignition loss 33.6 and various

[0063] This slurry is mixed with the principal slurry and the digestion is maintained for 5 minutes. the quantity of alumina dissolved is such that the A / C weight ratio of the pregnant liquor reaches 1.25.

[0064] After flash, a first dilution was carried out, leading to a concentration of 168 g Na.sub.2O / l, then a settling at 104.degree. C., in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com