High-quality impregnant asphalt production process

A production process and impregnating agent technology, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, tar pitch/petroleum pitch/natural pitch by distillation, petroleum industry, etc., which can solve the problem of low yield and ineffective It is difficult to remove asphalt impurities, difficult to control asphalt ash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

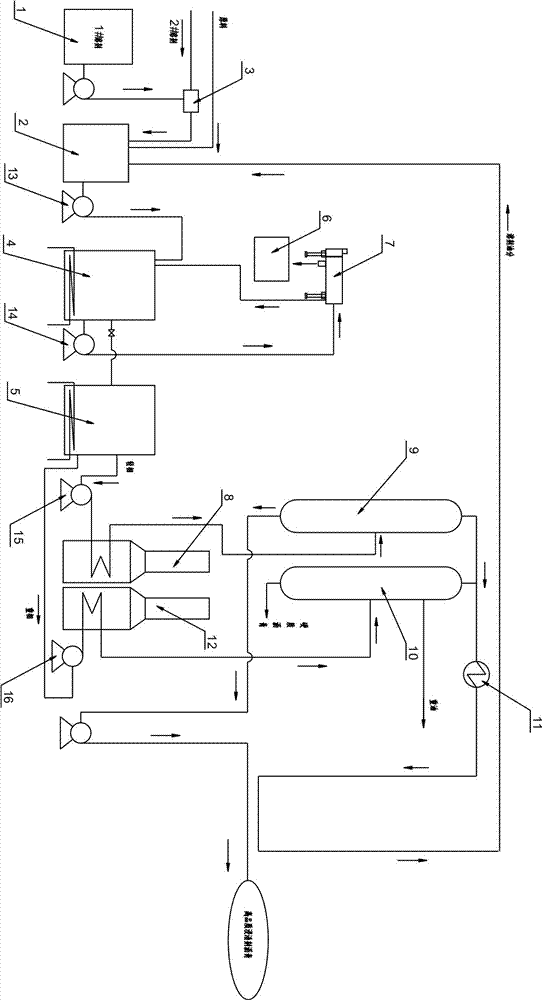

[0020] Such as figure 1 Shown: the production process of high-quality impregnating agent asphalt, which is to mix the first solvent kerosene and the second solvent wash oil stored in the solvent tank 1 with the pipeline mixer 3 according to the mass ratio of 1:1.6 into the stirring tank 2, and the raw material coal tar pitch is sent into the stirring tank for stirring, and the mass ratio of the raw material coal tar pitch and the extraction solvent is 1:1.5, and is pumped into the first settling tank 4 through the first oil pump 13, and the first The heavy phase part in the settling tank is pumped into the quinoline insoluble matter centrifugal removal device through the second oil pump 14, and the quinoline insoluble matter centrifugal removal device includes a super centrifuge 7 and a slag hopper connected with the super centrifuge 8. The quinoline insoluble slag is removed by centrifugation with a super centrifuge, the removed quinoline insoluble slag is collected in the sl...

Embodiment 2

[0024] The production process of high-quality impregnating agent asphalt, which is to mix the first solvent kerosene and the second solvent washing oil stored in the solvent tank 1 with the mass ratio of 1:2 with the pipeline mixer 3 and then send them into the mixing tank 2. At the same time, send the raw coal tar pitch into the stirring tank for stirring. The mass ratio of the raw coal tar pitch and the extraction solvent is 1:2, and then pump it into the first settling tank 4 through the first oil pump 13, and put it into the first settling tank The heavy phase part is pumped into the quinoline insoluble matter centrifugal removal device through two oil pumps 14, and described quinoline insoluble matter centrifugal removal device comprises super centrifuge 7 and the slag hopper 8 that links to each other with super centrifuge, by super centrifuge The centrifuge centrifuges to remove the quinoline-insoluble slag, the removed quinoline-insoluble slag is collected in the slag h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com