New method for obtaining cellulose-rich material from straws by two-step method by adopting ionic liquids

A technology of ionic liquid and cellulose, which is applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of high reaction pressure, long time, and reduction of cellulose crystallinity, and achieve mild reaction conditions, low production cost, and high crystallinity. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

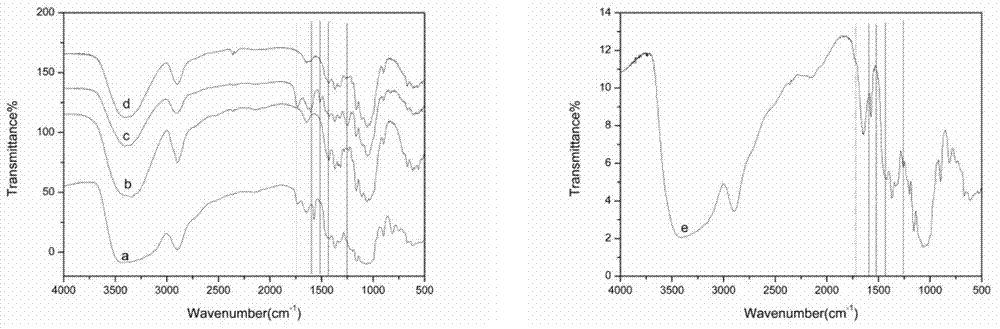

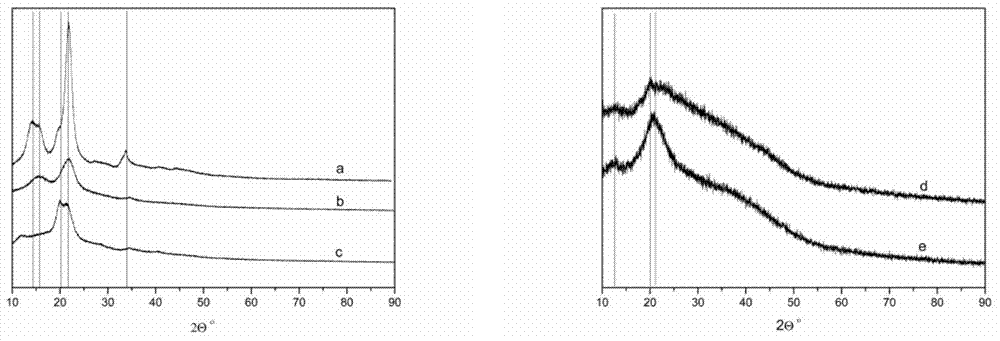

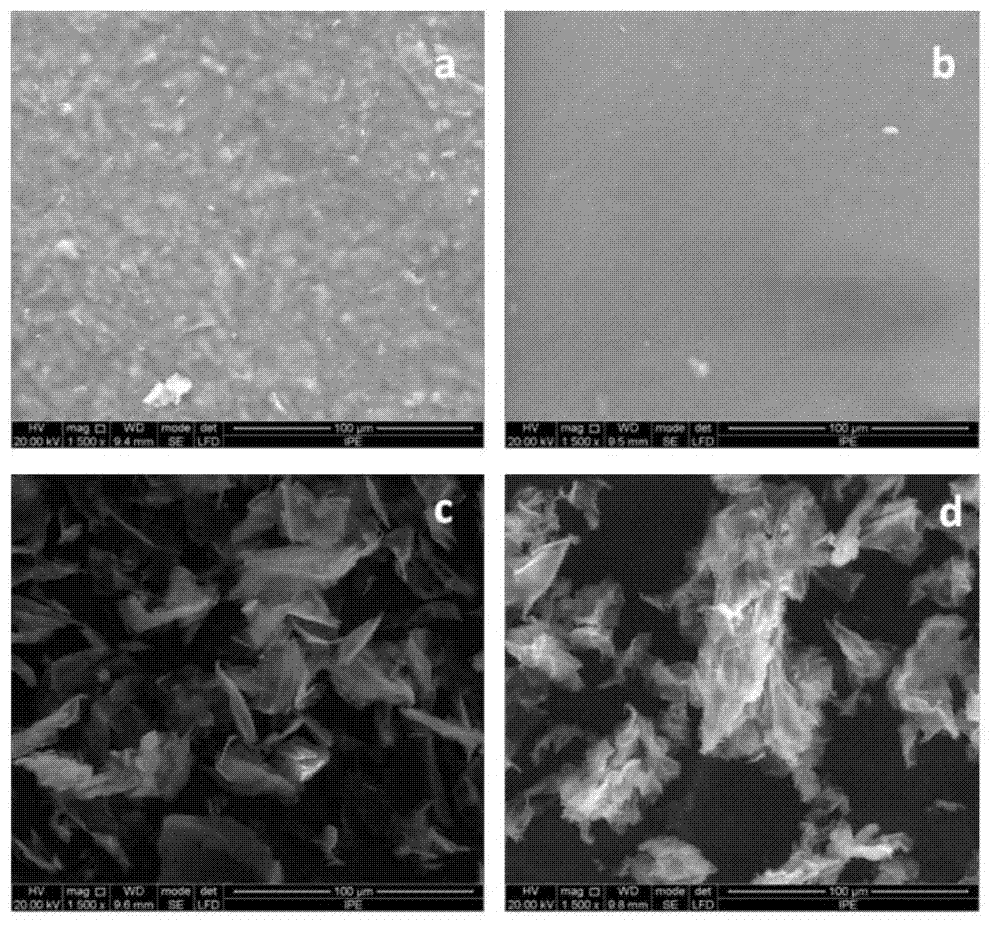

Embodiment 1

[0020] Weigh about 1.0964g of straw powder after washing with neutral detergent, add it into 20mL of 50wt% choline hydroxide (ChOH) aqueous solution, stir at room temperature for 3 hours, centrifuge the residue and supernatant, and then wash the residue with 60mL Distilled water was washed three times, filtered and dried to obtain a residue of 0.5218g, and the dissolution rate of the straw in the solution reached 47.59%. The content of hemicellulose in the analysis residue was 31.22%, the content of cellulose was 56.71%, that is, the content of cellulose was 87.93%, and the content of lignin was 12.07%.

[0021] Weigh about 0.5000g of the above residue, add it into 10.0028g of 1-ethyl-3-methylimidazolium phosphate ([Emim][DMP]) ionic liquid, heat to 130°C and magnetically stir for 5-10min to completely dissolve , No residue remains, and the dissolution rate reaches 100%. Cool to normal temperature after stopping the reaction, add 10mL DMSO to dilute the reaction solution, add...

Embodiment 2

[0023] Weigh about 1.0964g of straw powder after washing with neutral detergent, add it into 20mL of 50wt% choline hydroxide (ChOH) aqueous solution, stir at room temperature for 3 hours, centrifuge the residue and supernatant, and then wash the residue with 60mL Distilled water was washed three times, filtered and dried to obtain a residue of 0.5218g, and the dissolution rate of the straw in the solution reached 47.59%. The content of hemicellulose in the analysis residue was 31.22%, the content of cellulose was 56.71%, that is, the content of cellulose was 87.93%, and the content of lignin was 12.07%.

[0024] Weigh about 0.5022g of the above residue, add it to 10.0244g of 1-ethyl-3-methylimidazole acetic acid ([Emim][OAc]) ionic liquid, heat to 130°C and magnetically stir for 30min to completely dissolve, and no residue remains. The dissolution rate reaches 100%. After the reaction was stopped, it was cooled to room temperature, and 10 mL of DMSO was added to dilute the re...

Embodiment 3

[0026] Weigh about 1.0964g of straw powder after washing with neutral detergent, add it into 20mL of 50wt% choline hydroxide (ChOH) aqueous solution, stir at room temperature for 3 hours, centrifuge the residue and supernatant, and then wash the residue with 60mL Distilled water was washed three times, filtered and dried to obtain a residue of 0.5218g, and the dissolution rate of the straw in the solution reached 47.59%. The content of hemicellulose in the analysis residue was 31.22%, the content of cellulose was 56.71%, that is, the content of cellulose was 87.93%, and the content of lignin was 12.07%.

[0027] Weigh about 0.5000g of the above residue, add it into 9.8572g of 1-ethyl-3-methylimidazolium chloride salt ([Emim]Cl) ionic liquid, heat to 130°C and magnetically stir for 50min to dissolve completely, no residue remains, dissolve rate reached 100%. After the reaction was stopped, it was cooled to room temperature, and 10 mL of DMSO was added to dilute the reaction so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com