Oil soluble cationic broad-spectrum temporary blocking agent in use for drilling fluid

A cationic, oil-soluble technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temporary plugging effect and difficulty in obtaining it, so as to improve the water absorption capacity of water wells, simple use process, and improve perfection degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

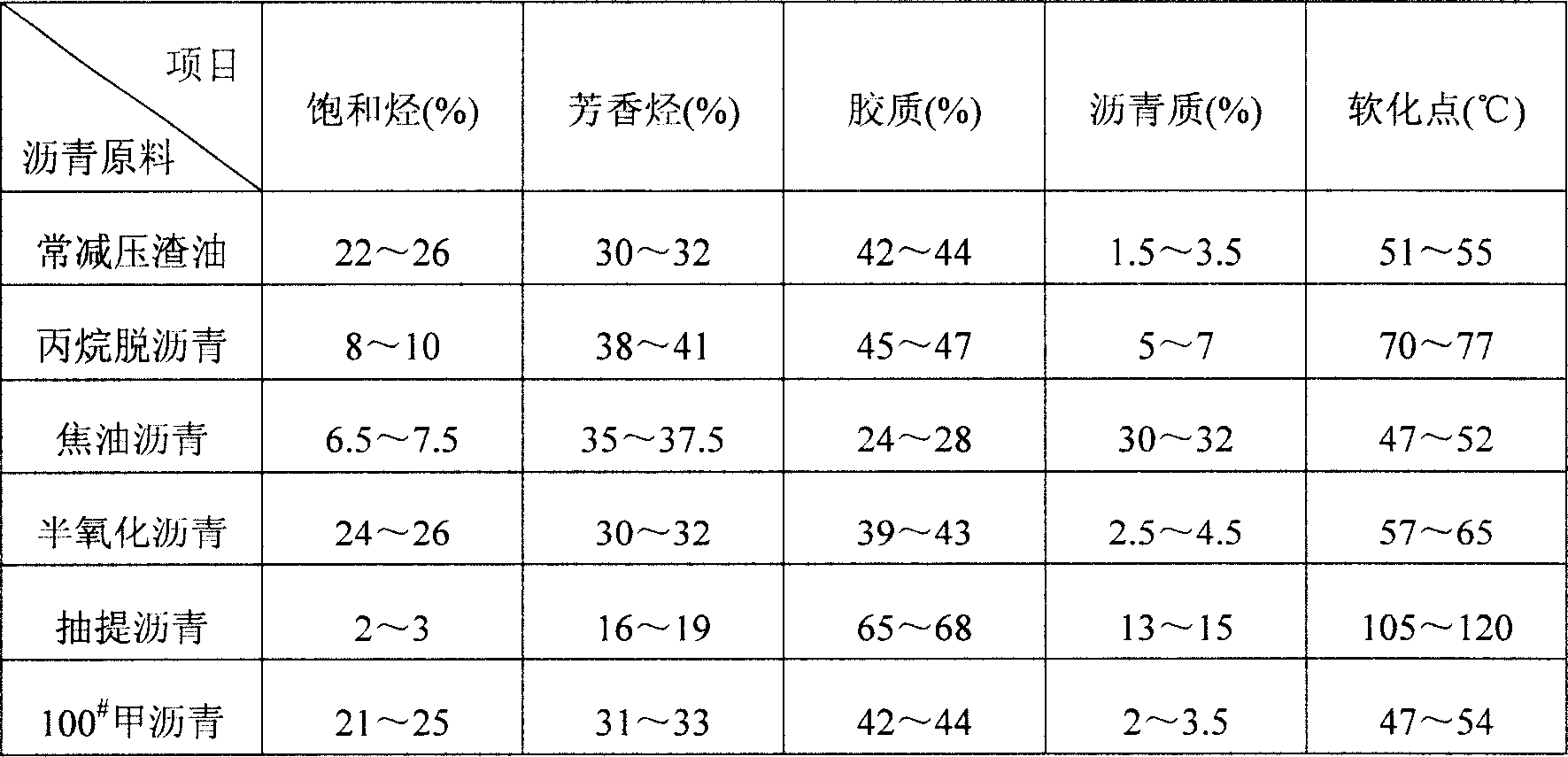

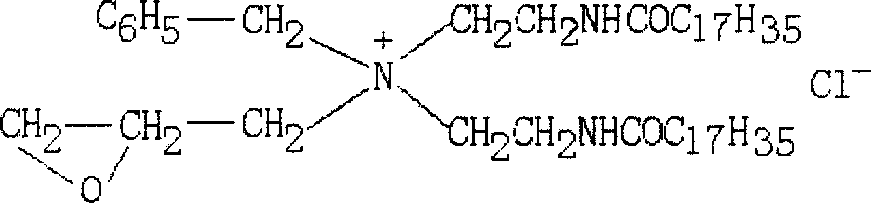

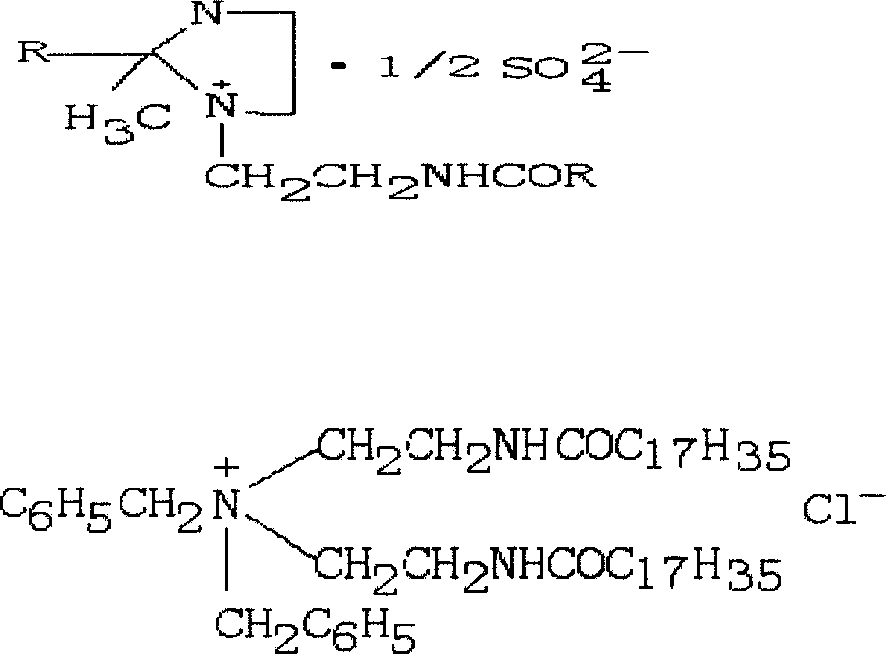

Embodiment 1

[0038] Atmospheric and vacuum residual asphalt, semi-oxidized asphalt, ethylene pyrolysis tar pitch, propane deasphalt, extracted asphalt and 100 #A heavy oil asphalt raw material is heated and melted at 120-130°C in a mass ratio of 1:2:1.5:3.5:3:1.75, and 0.2% of styrene-butadiene-styrene block copolymer ( accounted for the mass ratio of the total system), and mixed uniformly to obtain oil-soluble raw materials; at the same time, the aqueous solution of emulsifier RHJ-I, RHJ-II and RHJ-III was heated to 50-60°C (the addition amount was 0.65%, 0.7% of the total system, respectively %, 0.7%), add 0.2% calcium chloride and 0.2% carboxymethyl cellulose to the emulsifier aqueous solution, continue stirring evenly and keep it between 50-60°C; add preheated Grind the modified oil-soluble material at 120-130°C and the preheated emulsifier aqueous solution (the mass ratio of oil-soluble raw material to emulsifier aqueous solution is 60:40) to prepare the oil-soluble cationic new type ...

Embodiment 2

[0040] Atmospheric and vacuum residual asphalt, semi-oxidized asphalt, ethylene pyrolysis tar pitch, propane deasphalt, extracted asphalt and 100 # A heavy oil asphalt raw material is mixed evenly at a mass ratio of 1:2.5:1.88:3.75:3.12:2, heated and melted at 120-130°C, and 0.44% of styrene-butadiene-styrene block copolymer is added (accounting for the mass ratio of the total system) to obtain oil-soluble raw materials, and simultaneously heat the aqueous solution of the emulsifiers RHJ-I, RHJ-II and RHJ-III to 50-60°C (the additions are 0.5%, 0.62%, and 0.62%), add 0.25% calcium chloride and 0.17% hydroxyethyl cellulose to the emulsifier aqueous solution, continue stirring evenly and keep between 50~60 ℃; The physical and chemical properties of the new oil-soluble cationic broad-spectrum temporary plugging agent for liquid use are shown in the table.

Embodiment 3

[0042] Atmospheric and vacuum residual asphalt, semi-oxidized asphalt, ethylene pyrolysis tar pitch, propane deasphalt, extracted asphalt and 100 # A thick oil asphalt raw material is mixed uniformly at a mass ratio of 1:1.88:1.25:3.12:2.5:1.5 to obtain an oil-soluble raw material, which is heated and melted at 120-130°C, and styrene-butadiene-styrene embedded segment copolymer 0.3% (accounting for the mass ratio of the total system), mixed evenly to obtain an oil-soluble raw material; simultaneously, the aqueous solution of the emulsifier RHJ-I, RHJ-II and RHJ-III was heated to 50~60°C (the addition amount was respectively the total 0.89%, 0.96%, 0.96% of the system), add 0.22% calcium chloride and 0.84% carboxymethyl cellulose to the emulsifier aqueous solution, continue stirring evenly and keep it between 50-60°C; then follow the above The physical and chemical performance indicators of the oil-soluble cationic new broad-spectrum temporary plugging agent for drilling flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com