Process for nano-scaled graphene plates

a graphene plate and nano-scale technology, applied in the direction of nano-carbon, material nanotechnology, carbon compounds, etc., can solve the problems of increasing cost, complicated, slow and expensive purification process, and only about 15% yield of pure carbon nanotubes with respect to the end product, so as to reduce cost, wide property range, and process ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

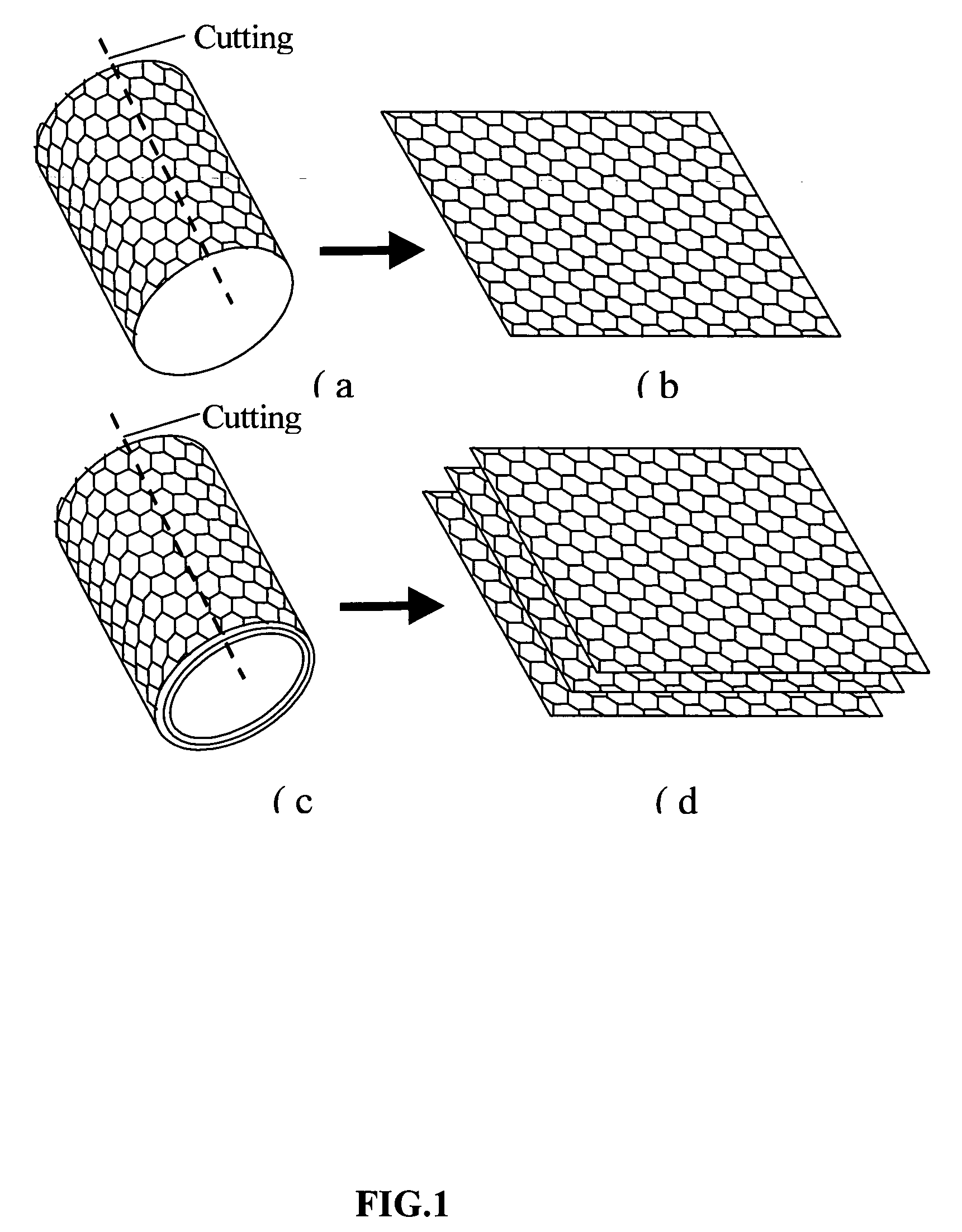

Image

Examples

example 1

[0038] One hundred grams of polymeric carbon, prepared by oxidation of PAN fibers at 250° C. and partial carbonization of the oxidized PAN at 500° C., were treated in a mixture of sulfuric and nitric acids at concentrations to yield the desired intercalation compound. The product was water washed and dried to approximately 1% by weight water. The dried fibers were introduced into a furnace at 1,250° C. to effect extremely rapid and high expansions of nano-scaled graphite crystallites. The exfoliated carbon sample, chopped into a short fiber form (<1 mm length), was then ball-milled in a high-energy plenary ball mill machine for 24 hours to produce nano-scaled particles.

example 2

[0039] Same as in Example 1, but the carbonization temperature was 1,000° C.

example 3

[0040] A phenol formaldehyde resin was heat treated in an inert atmosphere at a HTT in the range of 350-900° C. to obtain polymeric carbon, which was ground to mm-sized particles and then subjected to solution treatments to obtain exfoliated polymeric carbons. Samples containing exfoliated graphite crystallites were then ball-milled to become nanometer-sized powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com