Co-production technique of needle coke, mesocarbon microbeads and high-quality asphalt

A technology of mesophase carbon microspheres and process methods, applied in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by distillation, and processing tar pitch/petroleum pitch/natural pitch by chemical methods In other directions, it can solve the problems of not being effectively and rationally processed and utilized, insufficient coal tar pitch processing depth, and poor ability to resist market risks, so as to achieve timely adaptation to market changes, flexible and adjustable product indicators, and reduce market risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

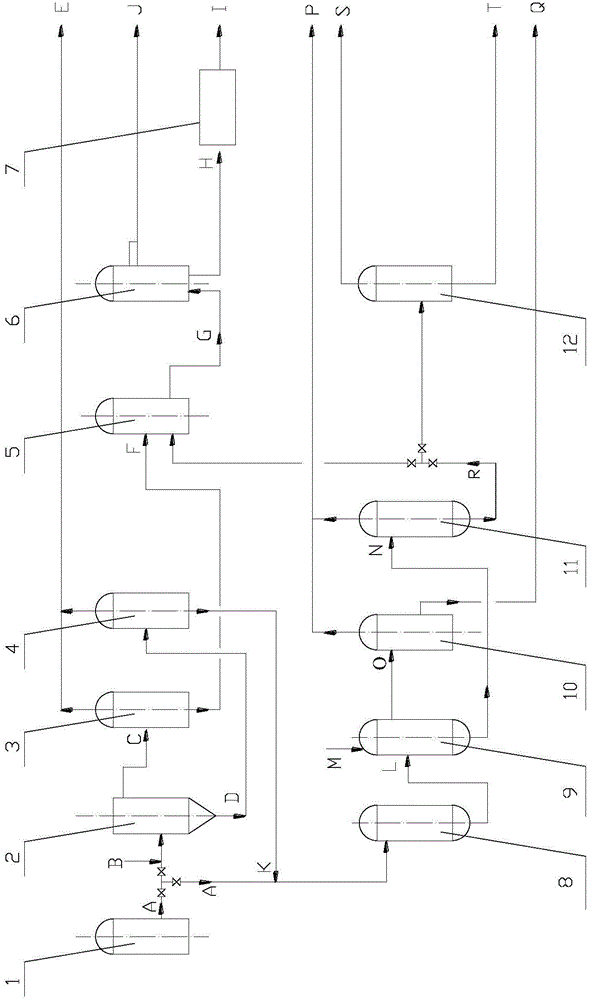

Method used

Image

Examples

Embodiment 1

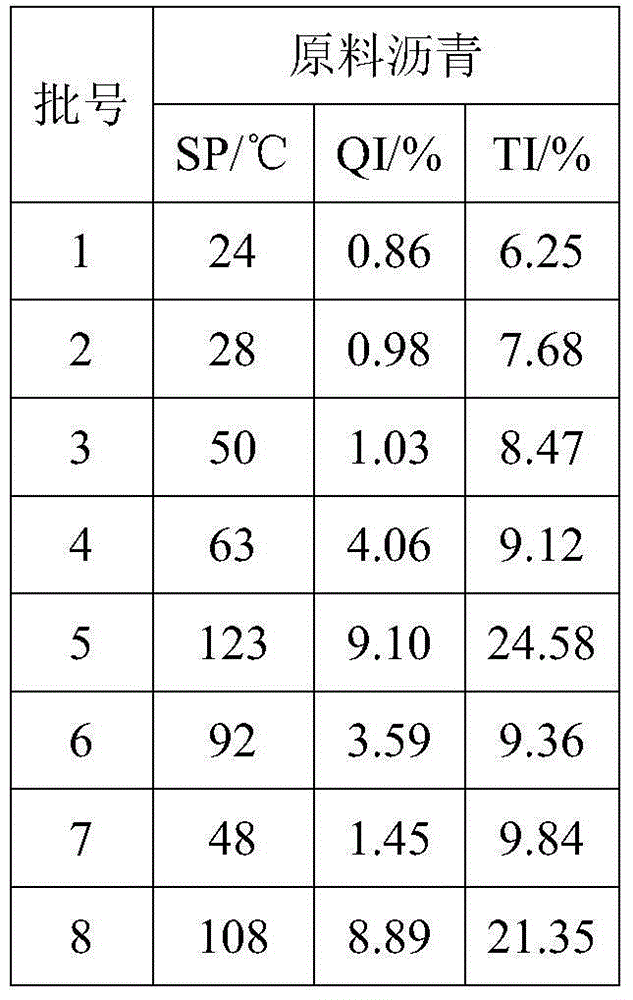

[0049] It is produced by the joint production process of needle coke, mesophase carbon microspheres and high-quality pitch of the present invention, and the main indicators of 8 batches are recorded:

[0050] Table 1 Raw asphalt index of each batch

[0051]

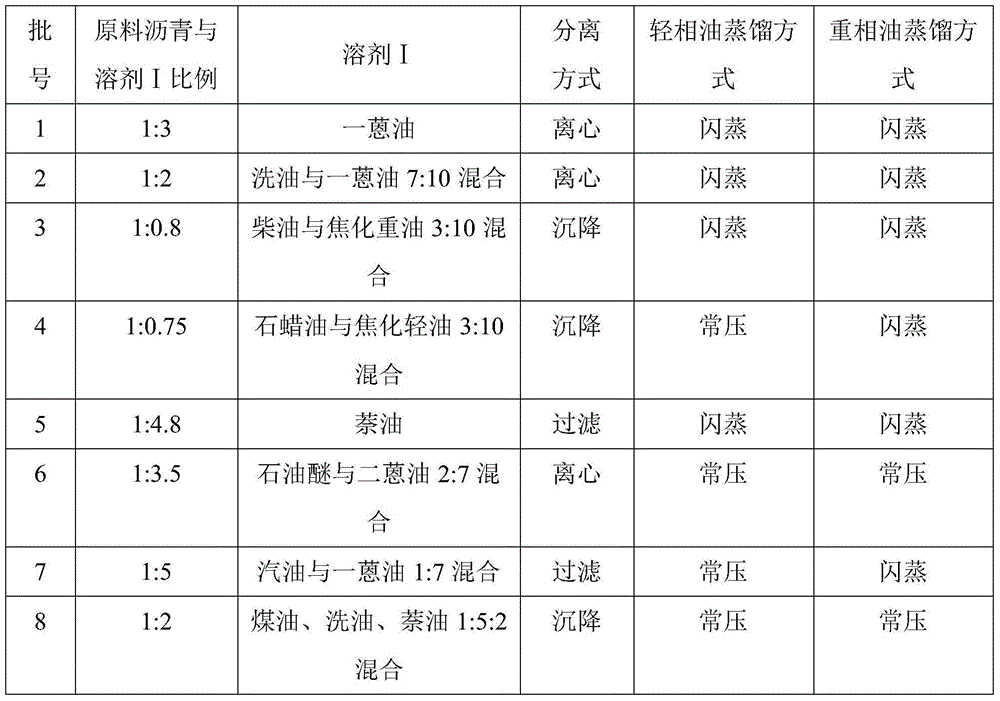

[0052] Table 2 Raw asphalt pretreatment process parameters

[0053]

[0054] Table 3 Polymerization parameters

[0055]

[0056] The separation and drying process parameters of the polymerization reaction product of table 4

[0057]

[0058] Table 5 By-product asphalt modification treatment methods and high-quality asphalt indicators

[0059]

[0060] Table 6 coking and calcination process parameters

[0061]

[0062] Table 7 Performance indicators of needle coke products

[0063] batch number

True density / g·cm -1

Ash / %

Graphitized CTE / (10 -6 ·℃ -1 )

1

2.11

0.21

1.3

2

2.14

0.16

1.2

3

2.13

0.23

1.15

4

2.12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com