Production method and system of coal-series needle coke

A production method and production system technology, which are applied in coke ovens, coking carbonaceous materials, petroleum industry, etc., can solve the problems of increased solvent loss, difficult operation, and difficulty in precise control of industrial devices, and achieve small solvent loss and clear interface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

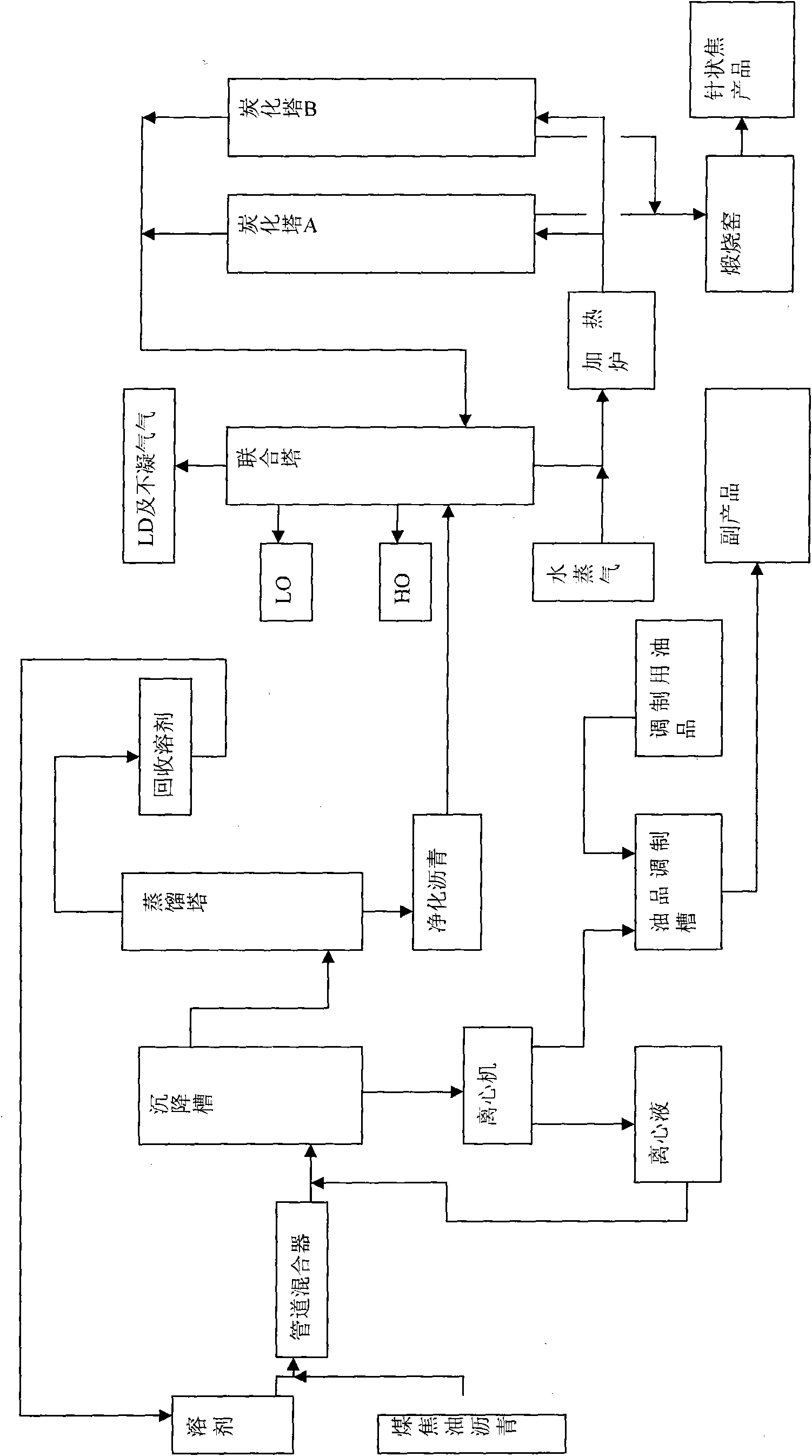

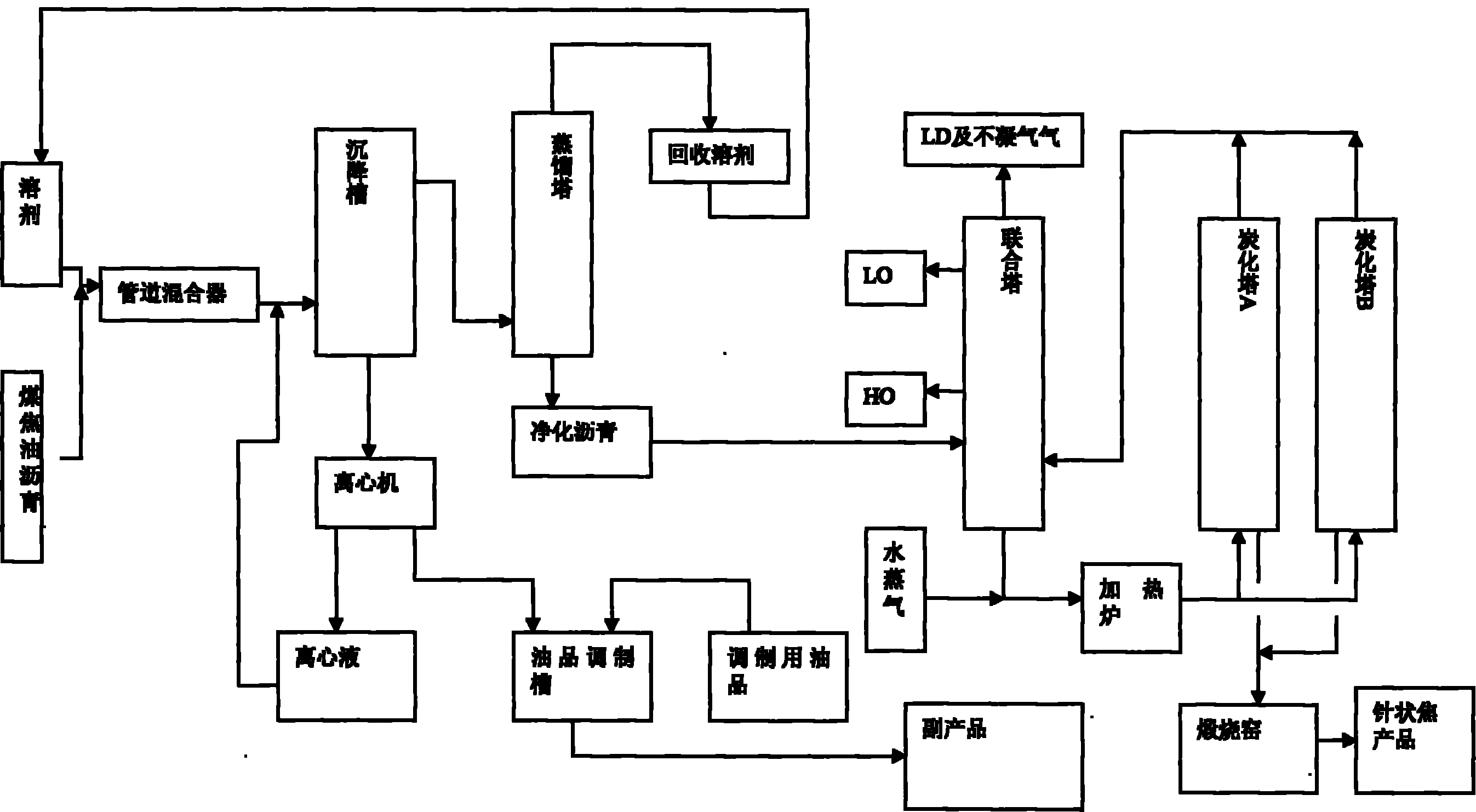

Method used

Image

Examples

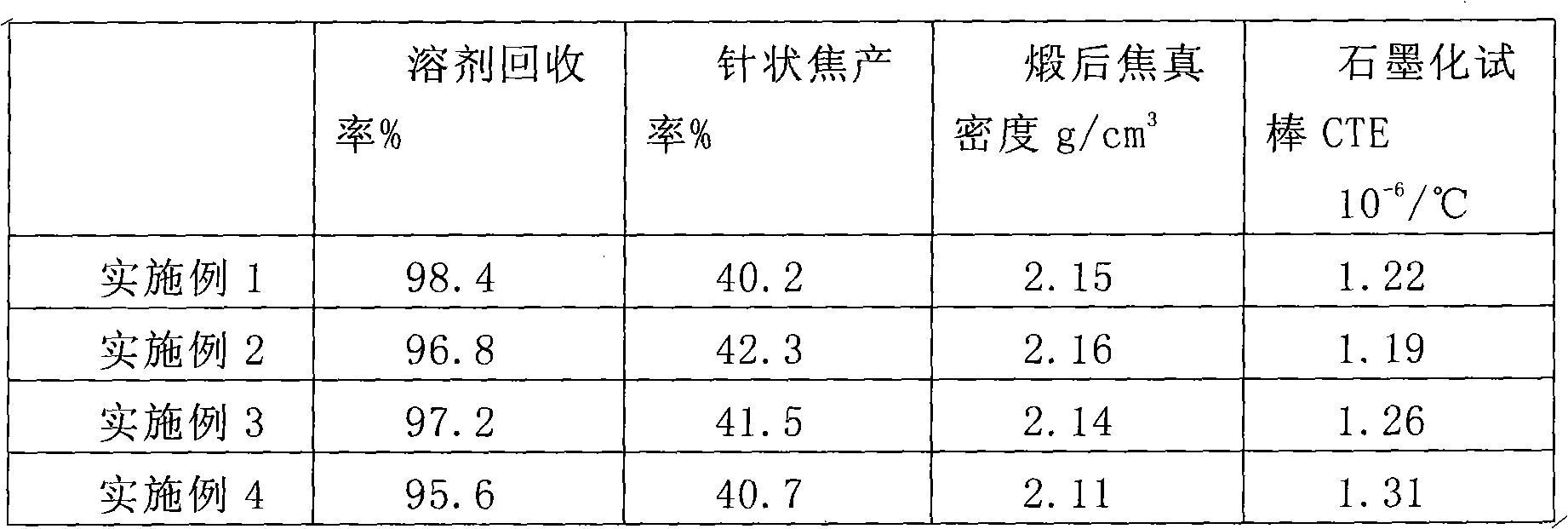

Embodiment 1

[0074] In this embodiment, coal tar pitch and solvent are mixed to obtain a mixture of coal tar pitch and solvent, wherein the mass flow ratio of coal tar pitch and solvent is 1:0.8. The temperature of the settling tank was 120°C. The residence time of the mixture of coal tar pitch and solvent in the settling tank was 15 hours. The mass flow ratio of continuously discharging the light phase from the light phase outlet of the settling tank to continuously discharging the heavy phase from the heavy phase outlet of the settling tank is 5:2. The operating pressure of the combined tower is 180KPa, and the bottom temperature of the combined tower is 320°C. The outlet temperature of the heating furnace is 470° C., and the ratio of the steam injection amount of the heating furnace to the feeding amount of the heating furnace is 0.03:1. The operating pressure of the carbonization tower is 300KPa, the reaction time in the carbonization tower is 8 hours, and the reaction temperature is...

Embodiment 2

[0079] In this embodiment, coal tar pitch and solvent are mixed to obtain a mixture of coal tar pitch and solvent, wherein the mass flow ratio of coal tar pitch and solvent is 1:1.5. The temperature of the settling tank was 95°C. The residence time of the mixture of coal tar pitch and solvent in the settling tank was 6 hours. The mass flow ratio of continuously discharging the light phase from the light phase outlet of the settling tank to continuously discharging the heavy phase from the heavy phase outlet of the settling tank is 10:2. The operating pressure of the combined tower is 250KPa. The temperature at the bottom of the combined tower is 380°C. The outlet temperature of the heating furnace is 480°C, and the ratio of the steam injection amount of the heating furnace to the feeding amount of the heating furnace is 0.06:1. The operating pressure of the carbonization tower is 350Kpa, the reaction time in the carbonization tower is 4 hours, and the reaction temperature i...

Embodiment 3

[0084] In this embodiment, coal tar pitch and solvent are mixed to obtain a mixture of coal tar pitch and solvent, wherein the mass flow ratio of coal tar pitch and solvent is 1:1.2. The temperature of the settling tank was 60°C. The residence time of the mixture of coal tar pitch and solvent in the settling tank was 1 hour. The mass flow ratio of continuously discharging the light phase from the light phase outlet of the settling tank to continuously discharging the heavy phase from the heavy phase outlet of the settling tank is 5:2. The operating pressure of the combined tower is 100KPa. The temperature at the bottom of the combined tower is 300°C. The outlet temperature of the heating furnace is 440°C, and the ratio of the steam injection amount of the heating furnace to the feeding amount of the heating furnace is 0.02:1. The operating pressure of the carbonization tower is 200KPa, the reaction time in the carbonization tower is 24 hours, and the reaction temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com