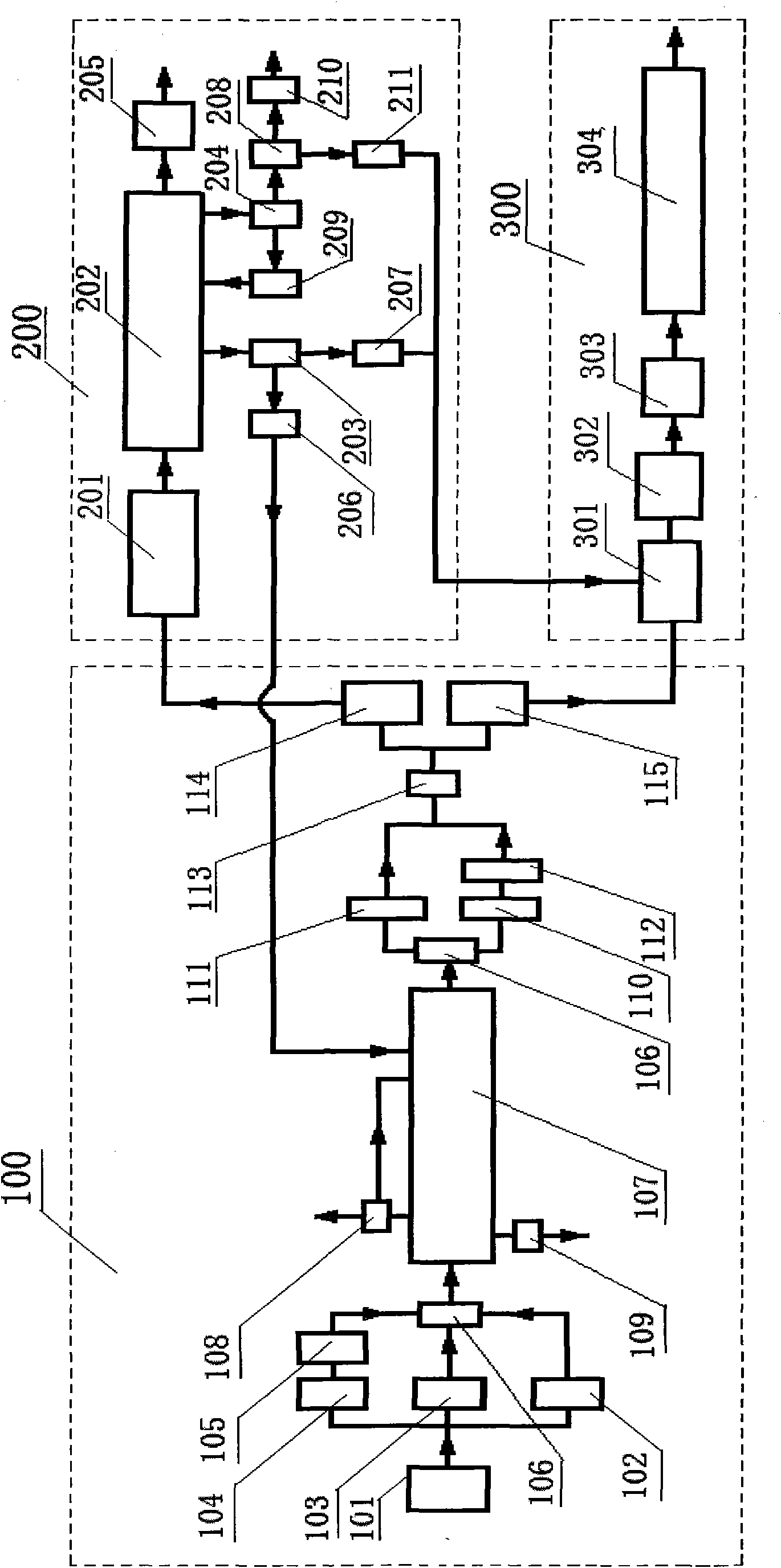

Large-scale brown coal quality-improving process and apparatus

A technology of lignite and process, applied in the field of large-scale lignite upgrading process and device, can solve the problem of no mature process technology and equipment that can be industrialized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

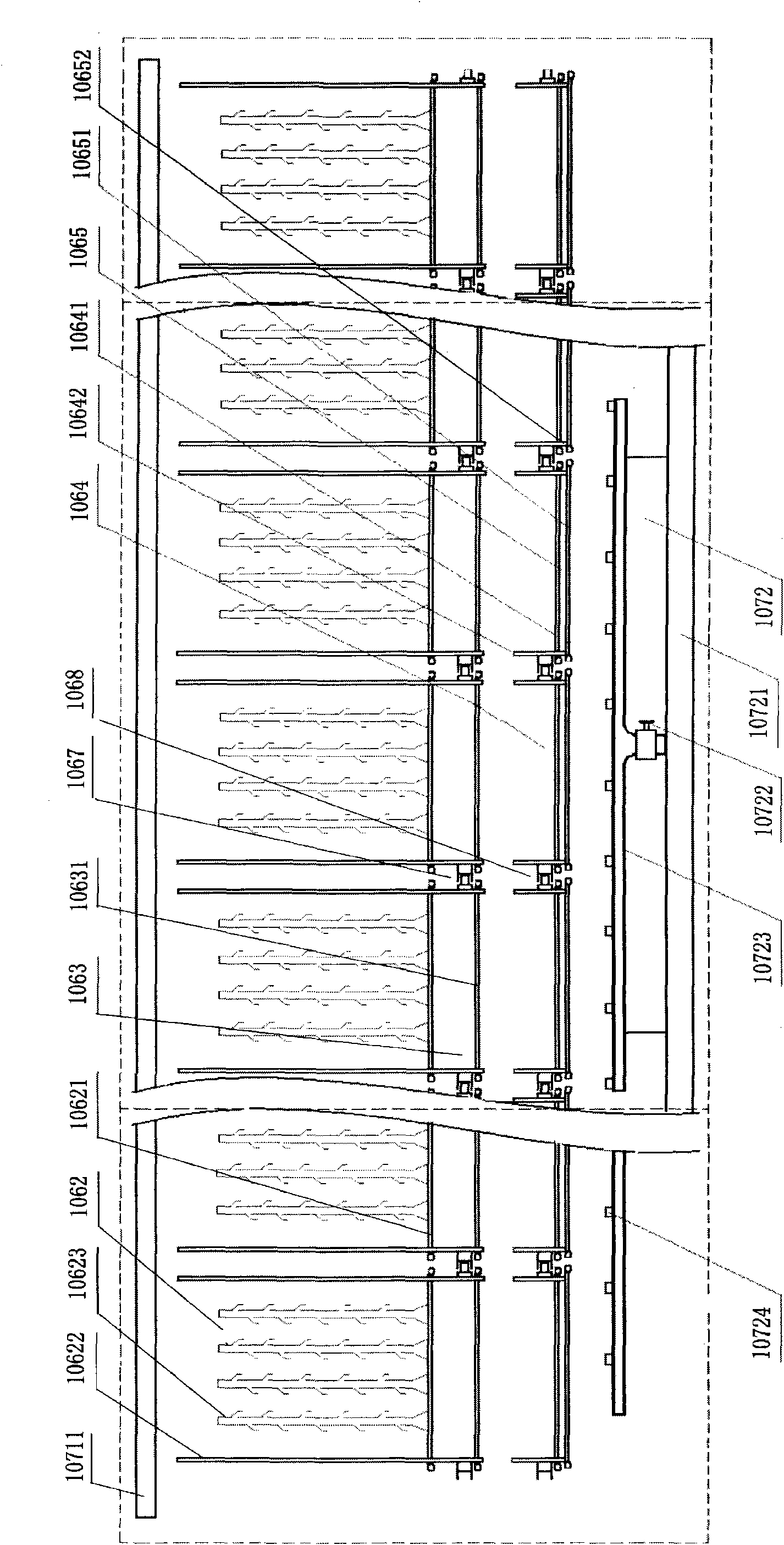

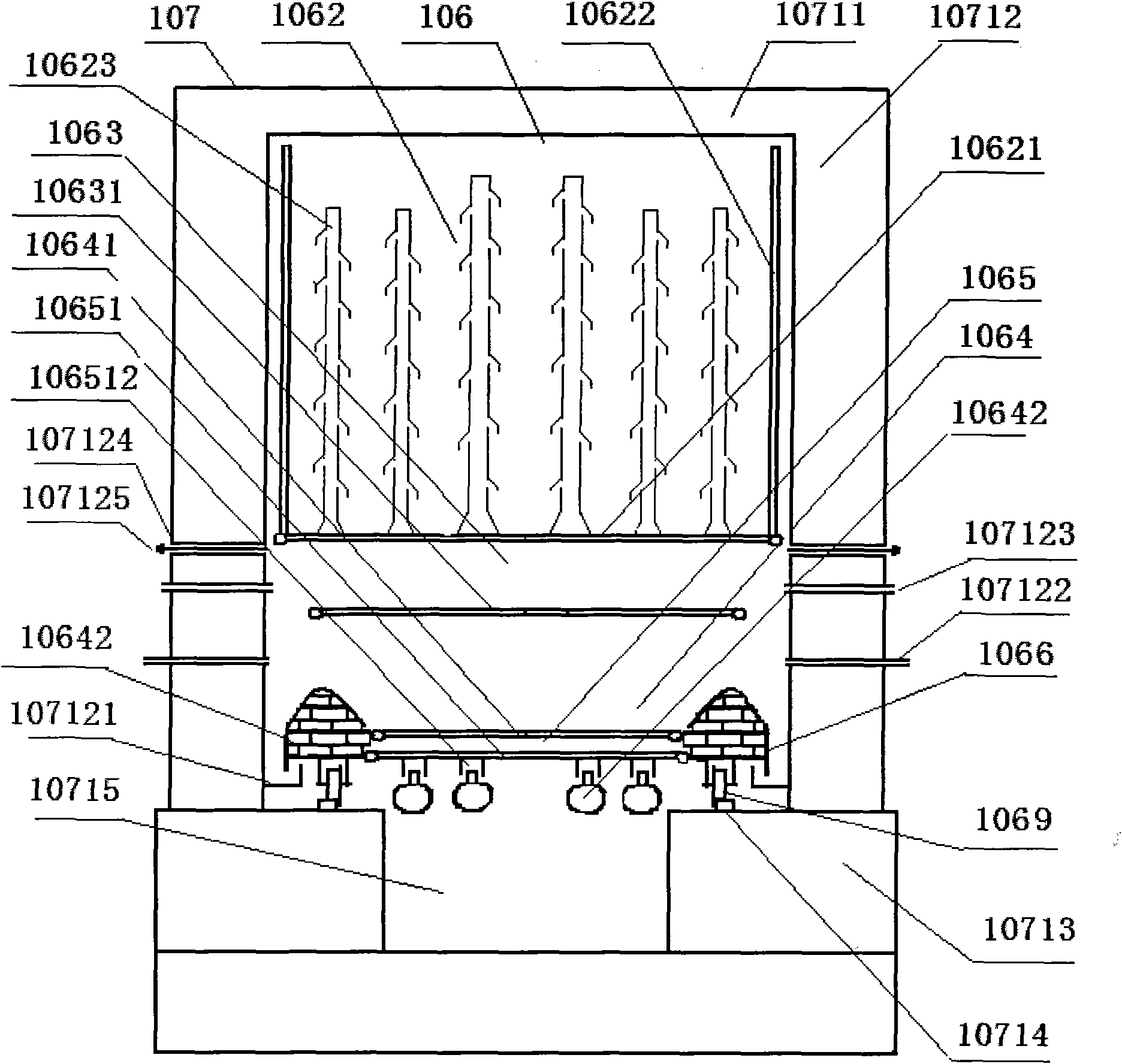

[0225] Embodiment: Process and device for processing 5 million tons of lignite per year

[0226] Parameters of tunnel internal heating lignite drying system:

[0227] One tunnel drying kiln with an inner section width of 5m, an inner height of 7.2m and a length of 198m is selected.

[0228] Specifications and quantity of drying vehicles: The size of drying vehicles is 4.6m×3.3m×6.9m, and the quantity is 90 vehicles, 60 vehicles running inside the kiln and 30 vehicles running outside the kiln.

[0229] Each car loads 60 tons of lignite raw materials, the drying cycle is 4.22 hours, the interval between drying vehicles is 4.22 minutes, and 853 tons of lignite raw materials with a water content of 30% (wet basis) are dried per hour, and the lignite raw materials with a water content of 30% (wet basis) are dried annually 5 million tons. The dried brown coal contains 10% moisture (wet basis), and the brown coal containing 10% moisture is 3.6 million tons / year. After grading, 1 / 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com