Preparation method of isostatic pressing microcrystalline graphite product

A technology of microcrystalline graphite and isostatic pressing, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cost, long production process, high energy consumption, etc., and achieve sufficient raw materials, fine and compact structure, The effect of high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

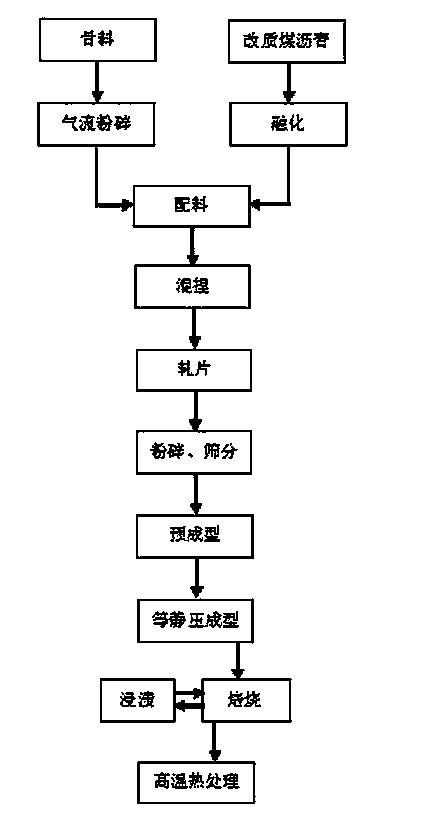

Method used

Image

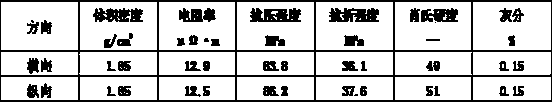

Examples

Embodiment 1

[0038] In this example, the binder is modified coal tar pitch, and its main performance indicators are: softening point 103°C; toluene insoluble matter 28.6%; quinoline insoluble matter 9.0%; volatile matter 54.2%; coking value 55.7%;

[0039] The impregnating agent is medium temperature coal tar pitch and high temperature coal tar pitch, and its main performance indicators are as follows:

[0040] Medium temperature coal tar pitch: softening point 85°C; toluene insoluble matter 24.4%; quinoline insoluble matter 7.6%; volatile matter 58.3%; coking value 52.6%; high temperature coal tar pitch: softening point 112°C; toluene insoluble matter 30.2%; 8.4%; volatile matter 53.3%; coking value 56.9%;

[0041] Aggregate is microcrystalline graphite, artificial graphite and electric calcined pitch coke, and its main performance indicators are as follows:

[0042] Microcrystalline graphite: ash content 0.32%; sulfur content 0.05%; true density 2.22g / cm 3 ;Powder resistivity 120μΩ·m; ...

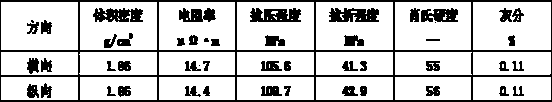

Embodiment 2

[0067] In this example, the binder is modified coal tar pitch, and its main performance indicators are: softening point 98°C; toluene insoluble matter 29.3%; quinoline insoluble matter 8.5%; volatile matter 54.8%; coking value 56.3%.

[0068] The impregnating agent is medium temperature coal tar pitch and high temperature coal tar pitch, and its main performance indicators are as follows:

[0069] Medium temperature coal tar pitch: softening point 80°C; toluene insoluble matter 22.7%; quinoline insoluble matter 6.8%; volatile matter 58.3%; coking value 53.1%;

[0070] High-temperature coal tar pitch: softening point 108°C; toluene insoluble matter 28.2%; quinoline insoluble matter 8.9%; volatile matter 54.1%; coking value 57.4%.

[0071] Aggregate is microcrystalline graphite, artificial graphite and electrocalcined pitch coke, and its main performance indicators are as follows:

[0072] Microcrystalline graphite: ash content 0.06%; sulfur content 0.03%; true density 2.24g / cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com