Activated carbon microspheres and preparation method thereof

A technology of active, carbon microspheres, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of low adsorption capacity and slow adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1 : the preparation method of activated carbon microspheres of the present invention.

[0089] The preparation steps are as follows:

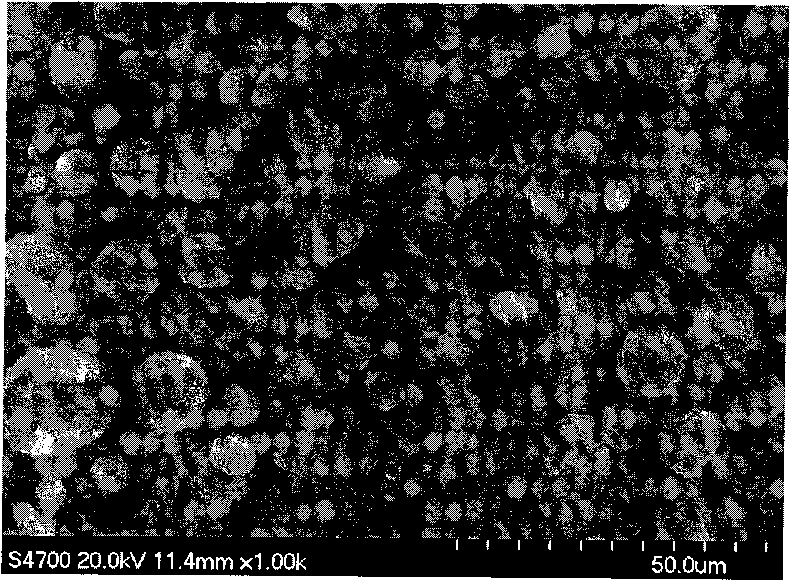

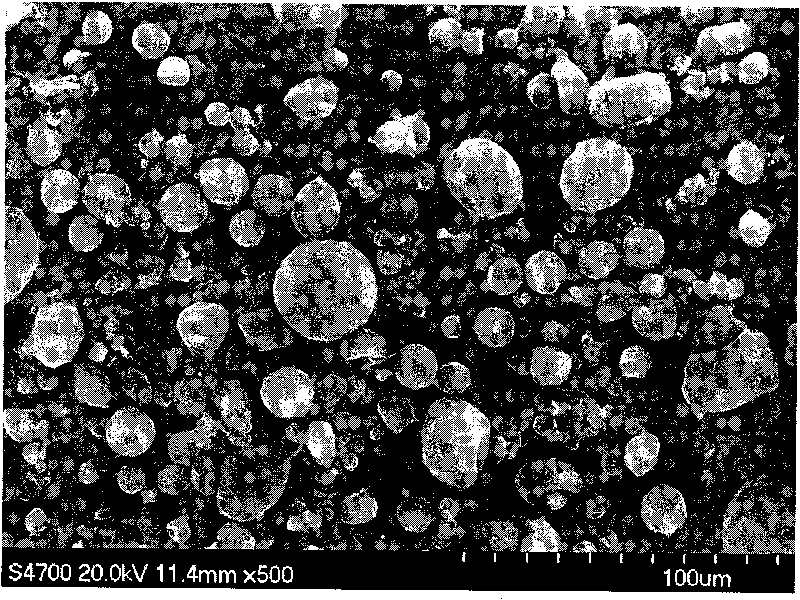

[0090] A. Use the QM-1SP planetary ball mill crushing equipment produced by Nanjing University Instrument Factory to pulverize the coal tar pitch that meets the national standard GB / T2290-94 to 200 mesh, weigh 100 grams of crushed coal tar pitch, and add 18 grams to the coal tar pitch Nano zirconia ceramic powder additive, stir and mix evenly with a glass rod, put it into a blast drying oven, carry out pre-oxidation in the air at a temperature of 350°C for 1.8 hours, and then maintain a constant temperature at a temperature of 480°C for 1.2 hours under a nitrogen atmosphere. Hour, then naturally cool to room temperature, obtain 109.8 grams of preoxidation product, use Hitachi S-4700 scanning electron microscope observation result to be listed in figure 1 , which shows that this preoxidation product is essentially spherical.

...

Embodiment 2

[0094] Example 2 : the preparation method of activated carbon microspheres of the present invention.

[0095] Carried out in the same manner as in Example 1, except that the nanometer titanium carbide ceramic powder additive was used.

[0096] The activated carbon microsphere material obtained in this example was also analyzed using the equipment and instruments described in the specification of this application, and the analysis results are listed in Table 1.

Embodiment 3

[0097] Example 3 : the preparation method of activated carbon microspheres of the present invention.

[0098] Carried out in the same manner as in Example 1, except that the nano-silicon nitride ceramic powder additive was used.

[0099] The activated carbon microsphere material obtained in this example was also analyzed using the equipment and instruments described in the specification of this application, and the analysis results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com