Technology for preparing needle coke raw material from coal-tar pitch

A needle coke raw material, coal tar pitch technology, applied in the field of coal chemical industry, can solve the problems of reducing the economic benefits of electrode preparation process, affecting the performance of needle coke electrodes, affecting the quality of graphite electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

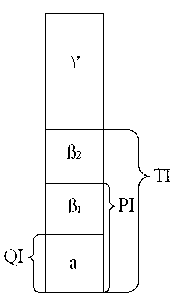

Image

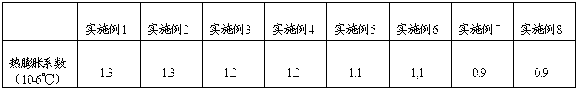

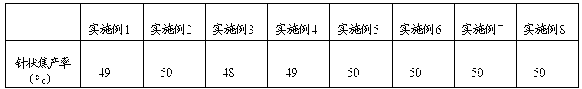

Examples

Embodiment 1

[0038] The process for preparing needle coke raw materials using coal tar pitch described in this embodiment includes:

[0039] (1) After the coal tar pitch and the solvent are fully mixed, the insoluble matter in the mixed solution is removed by filtration and separation;

[0040] Described solvent is the mixture of naphtha light oil and washing oil, and the mass ratio of described naphtha light oil and washing oil is 20:80; The mass ratio of described solvent and described asphalt is 0.5;

[0041] (2) Send the clarified liquid obtained after removing the insoluble matter into a separator to separate the light solvent in the clarified liquid to obtain a heavy fraction with low QI;

[0042] (3) Hydrotreating the heavy distillate in the presence of a hydrogenation catalyst, the temperature condition of the hydrotreatment is 300°C, the pressure is 5Mpa, and the hydrogenation catalyst described in this example is FeS 2 .

Embodiment 2

[0044] The process for preparing needle coke raw materials using coal tar pitch described in this embodiment includes:

[0045] (1) After fully mixing the asphalt and the solvent, remove the insoluble matter in the mixture by sedimentation and separation, and the sedimentation time is 6 hours;

[0046] Described solvent is the mixture of tar light oil and cresol oil, and the mass ratio of described tar light oil and cresol oil is 95:5; The mass ratio of described solvent and described asphalt is 10;

[0047] (2) Send the clarified liquid obtained after removing the insoluble matter into a separator to separate the light solvent in the clarified liquid to obtain a heavy fraction with low QI;

[0048] (3) Hydrotreating the heavy distillate in the presence of a hydrogenation catalyst, the temperature condition of the hydrotreatment is 450°C, the pressure is 20Mpa, and the hydrogenation catalyst described in this example is FeS 2 .

Embodiment 3

[0050] The process for preparing needle coke raw material using coal tar pitch described in this embodiment comprises the following steps:

[0051] (1) After fully mixing the asphalt and the solvent, remove the insoluble matter in the mixture by centrifugal separation, the relative centrifugal force of the centrifugal separation is 2500G;

[0052] Described solvent is the mixture of naphtha light oil and anthracene oil, and the mass ratio of described naphtha light oil and anthracene oil is 90:5; The mass ratio of described solvent and described asphalt is 5, carries out centrifugal separation The viscosity of the mixed solution is 40mpa·s;

[0053] (2) Send the clarified liquid obtained after removing the insoluble matter into a separator to separate the light solvent in the clarified liquid to obtain a heavy fraction with low QI;

[0054] (3) Hydrotreating the heavy distillate in the presence of a hydrogenation catalyst, the temperature condition of the hydrotreatment is 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com