Coal tar pitch for preparing needle coke, method for preparing same and solvent used in preparation process of coal tar pitch

A technology for coal tar pitch and coal tar, which is applied in the field of coal tar or coal tar pitch and its preparation, and can solve the problems of difficulty in preparing needle coke with high yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of coal tar pitch described in the present embodiment is:

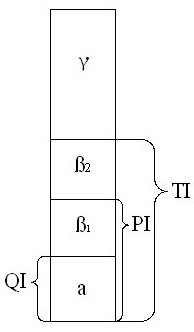

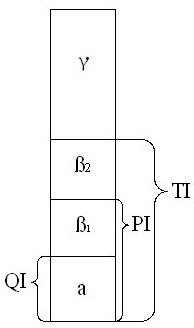

[0041] (1) Using 100 parts by weight of coal tar as a raw material, the coal tar contains the following components in mass percentages: QI 2.4%, PI 2.8%, TI 5.1%, β in the coal tar pitch 1 The mass percentage of the component is 0.4%, β 2 The mass percent of component is 2.3%;

[0042] Mix the coal tar pitch with 500 parts by weight of solvent, stir evenly, and centrifuge to separate solvent-insoluble matter; the solvent is a mixture of coal-based light oil and coal-based aromatic oil, wherein the coal-based light The oil is gas light oil, the coal series aromatic hydrocarbon oil is coker oil, and the mass ratio of coker oil to gas light oil is 10; the mass ratio of the solvent to the coal tar pitch raw material is 5.

[0043] (2) Under normal pressure, distill the residue after separating the solvent-insoluble matter in step (1) at 350°C, separate the solvent and the fraction between 0...

Embodiment 2

[0052] The preparation method of coal tar pitch described in the present embodiment is:

[0053] (1) Using 100 parts by weight of ordinary coal tar pitch as a raw material, the coal tar pitch contains the following components in mass percentages: QI 5.0%, PI 5.8%, TI 10.6%, and the coal tar pitch contains β 1 The mass percentage of the component is 0.8%, β 2 The mass percent of the component is 4.8%.

[0054] The coal tar pitch is mixed with 50 parts by weight of solvent, and after stirring evenly, the solvent insoluble matter is separated to obtain the coal tar pitch used for preparing needle coke; the solvent is coal-based light oil and coal-based aromatic oil. A mixture of hydrocarbon oils, wherein the coal-based light oil is tar light oil, the coal-based aromatic hydrocarbon oil is anthracene oil, and the mass ratio of the anthracene oil to tar light oil is 0.1; the solvent and the coal The mass ratio of the tar pitch raw material is 0.5.

[0055] The method for separat...

Embodiment 3

[0065] The preparation method of coal tar pitch described in the present embodiment is:

[0066] (1) Using 100 parts by weight of ordinary coal tar pitch as a raw material, the coal tar pitch contains the following components in mass percentages: QI 5.0%, PI 5.8%, TI 10.6%, and the coal tar pitch contains β 1 The mass percentage of the component is 0.8%, β 2 The mass percentage of component is 4.8%;

[0067] Mix the coal tar pitch with 120 parts by weight of solvent, stir evenly, and centrifuge to separate the solvent-insoluble matter; the solvent is a mixture of coal-based light oil and coal-based aromatic oil, wherein the coal-based light The oil is gas light oil, the coal series aromatic hydrocarbon oil is coker oil, and the mass ratio of the coker oil to the gas light oil is 9; the mass ratio of the solvent to the coal tar pitch raw material is 1.2.

[0068] (2) Under normal pressure, distill the residue after separating the solvent-insoluble matter in step (1) at 370° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com