Method for coal-tar-free preparation of desulfurization and denitrification activated carbon

A technology for desulfurization, denitrification, and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cost, volatile toxic and harmful substances in coal tar, achieve low price, reduce occupational health hazards, and use small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

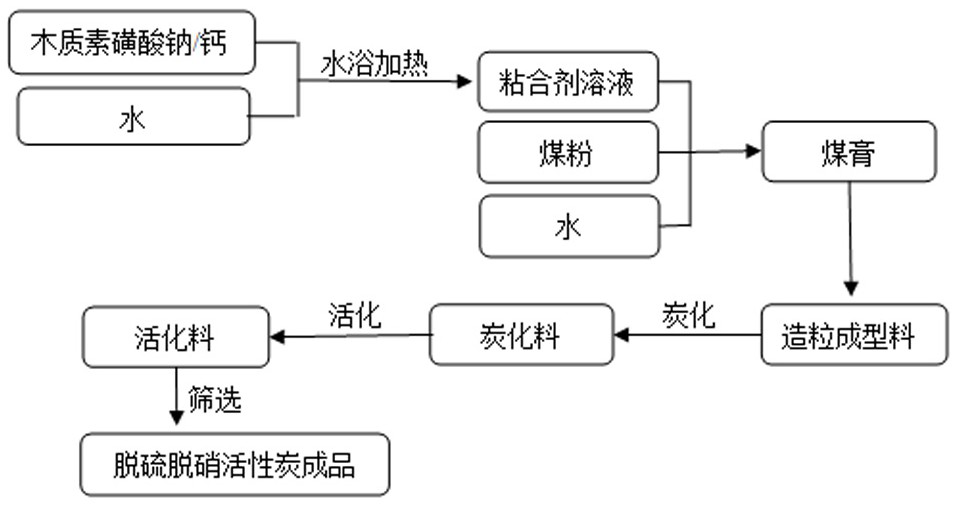

[0022] 1. Preparation of binder solution: use sodium lignosulfonate, mix it with water at a mass ratio of 2:3, let it stand in a water bath at 60-80°C for 4 hours, the sodium lignosulfonate / calcium is completely dissolved, and prepare into a solution, and the solution is used as a binder for the preparation of desulfurization and denitrification activated carbon.

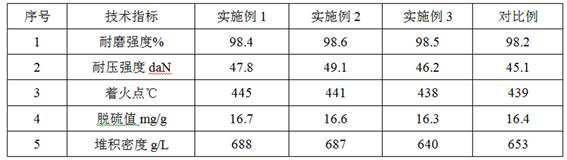

[0023] 2. Finished product preparation: Mix 80 parts of coal powder, 10 parts of binder solution, and 10 parts of water in proportion, and mix for 10 minutes to form coal paste, which is then shaped by a granulator. ℃-650℃ temperature gradient carbonization furnace, uniform carbonization for 1 hour (gradient carbonization is 350℃ for 5min, 450℃ for 5min, 550℃ for 5min, 650℃ for 5min, the heating rate is 10℃ / mim), enter to Activation furnace, uniform activation at 700°C-850°C temperature gradient for 2 hours (gradient activation is 700°C for 10 minutes, 750°C for 10 minutes, 800°C for 10 minutes, 850°C for 60 minutes...

Embodiment 2

[0025] 1. Preparation of binder solution: use calcium lignosulfonate, mix it with water at a mass ratio of 2:3, let it stand in a water bath at 60-80°C for 4 hours, the sodium / calcium lignosulfonate is completely dissolved, and prepare into a solution, and the solution is used as a binder for the preparation of desulfurization and denitrification activated carbon.

[0026] 2. Finished product preparation: Mix 78 parts of coal powder, 13 parts of binder solution, and 7 parts of water in proportion, and mix for 10 minutes to form coal paste, which is then molded by a granulator. ℃-650℃ temperature gradient carbonization furnace, uniform carbonization for 1 hour (gradient carbonization is 350℃ for 5min, 450℃ for 5min, 550℃ for 5min, 650℃ for 5min, the heating rate is 10℃ / mim), enter to Activation furnace, uniform activation at 700°C-850°C temperature gradient for 2 hours (gradient activation is 700°C for 10 minutes, 750°C for 10 minutes, 800°C for 10 minutes, 850°C for 60 minutes...

Embodiment 3

[0028] 1. Preparation of binder solution: use sodium lignosulfonate, mix it with water at a mass ratio of 2:3, let it stand in a water bath at 60-80°C for 4 hours, the sodium lignosulfonate / calcium is completely dissolved, and prepare into a solution, and the solution is used as a binder for the preparation of desulfurization and denitrification activated carbon.

[0029] 2. Finished product preparation: Mix 70 parts of coal powder, 15 parts of binder solution, and 5 parts of water in proportion, and mix for 10 minutes to form coal paste, which is then molded by a granulator. ℃-650℃ temperature gradient carbonization furnace, uniform carbonization for 1 hour (gradient carbonization is 350℃ for 5min, 450℃ for 5min, 550℃ for 5min, 650℃ for 5min, the heating rate is 10℃ / mim), enter to Activation furnace, uniform activation at 700°C-850°C temperature gradient for 2 hours (gradient activation is 700°C for 10 minutes, 750°C for 10 minutes, 800°C for 10 minutes, 850°C for 60 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com