Big bag feeding device

A technology of adding devices and large bags, which is applied in the field of large bag feeding devices, can solve problems such as low efficiency, fly ash leakage, occupational health damage of transporters, etc., and achieve the effect of high efficiency and reduction of occupational health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

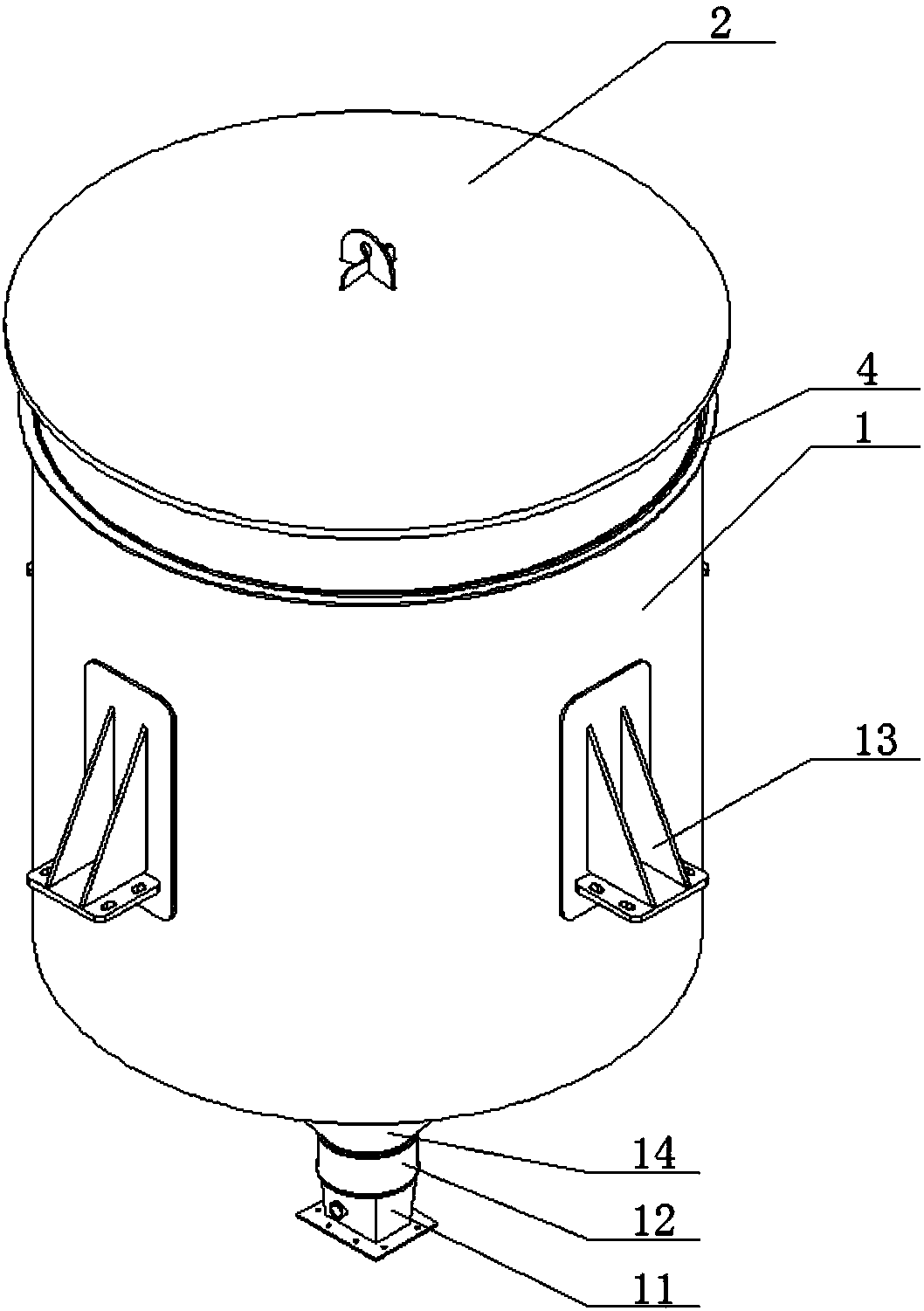

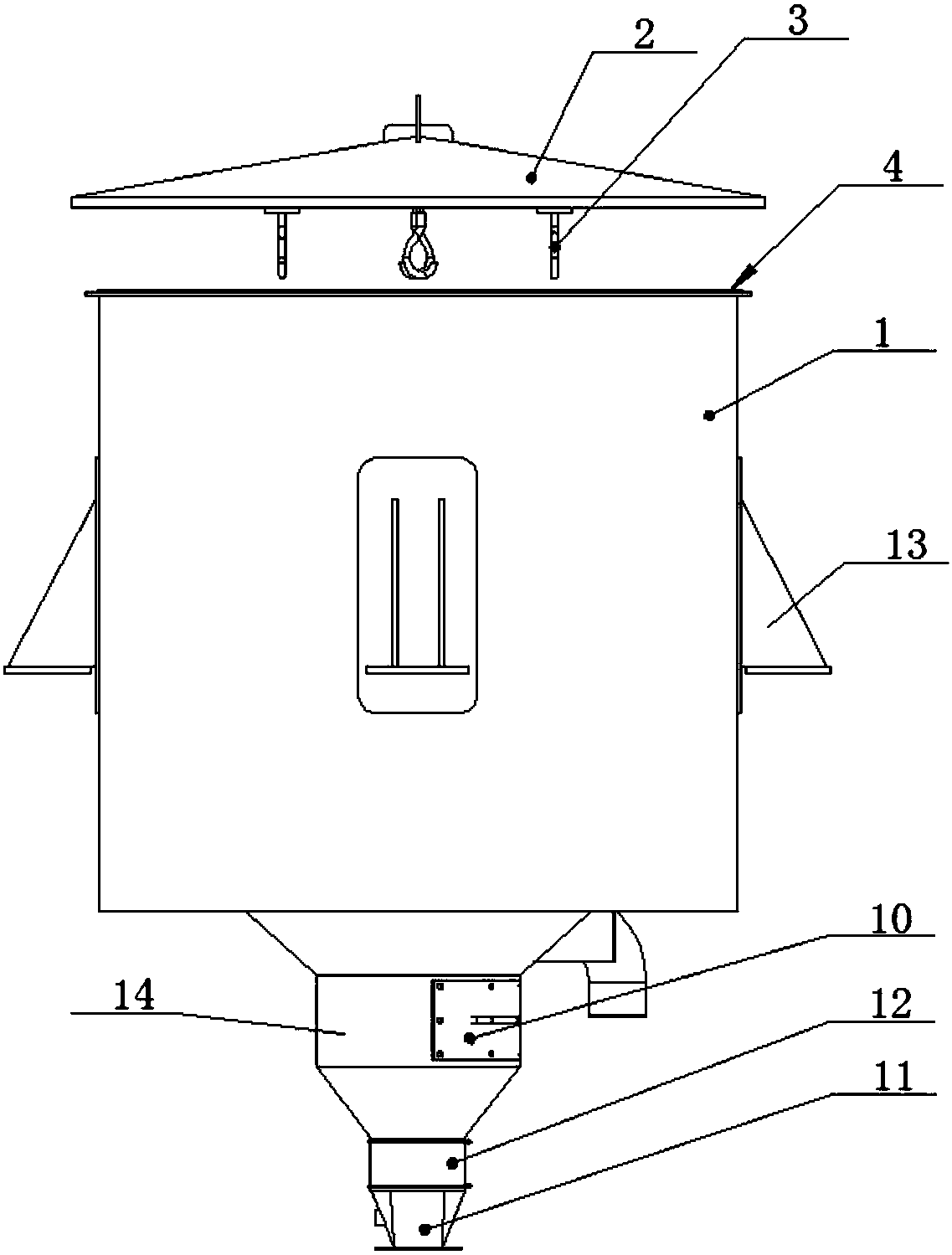

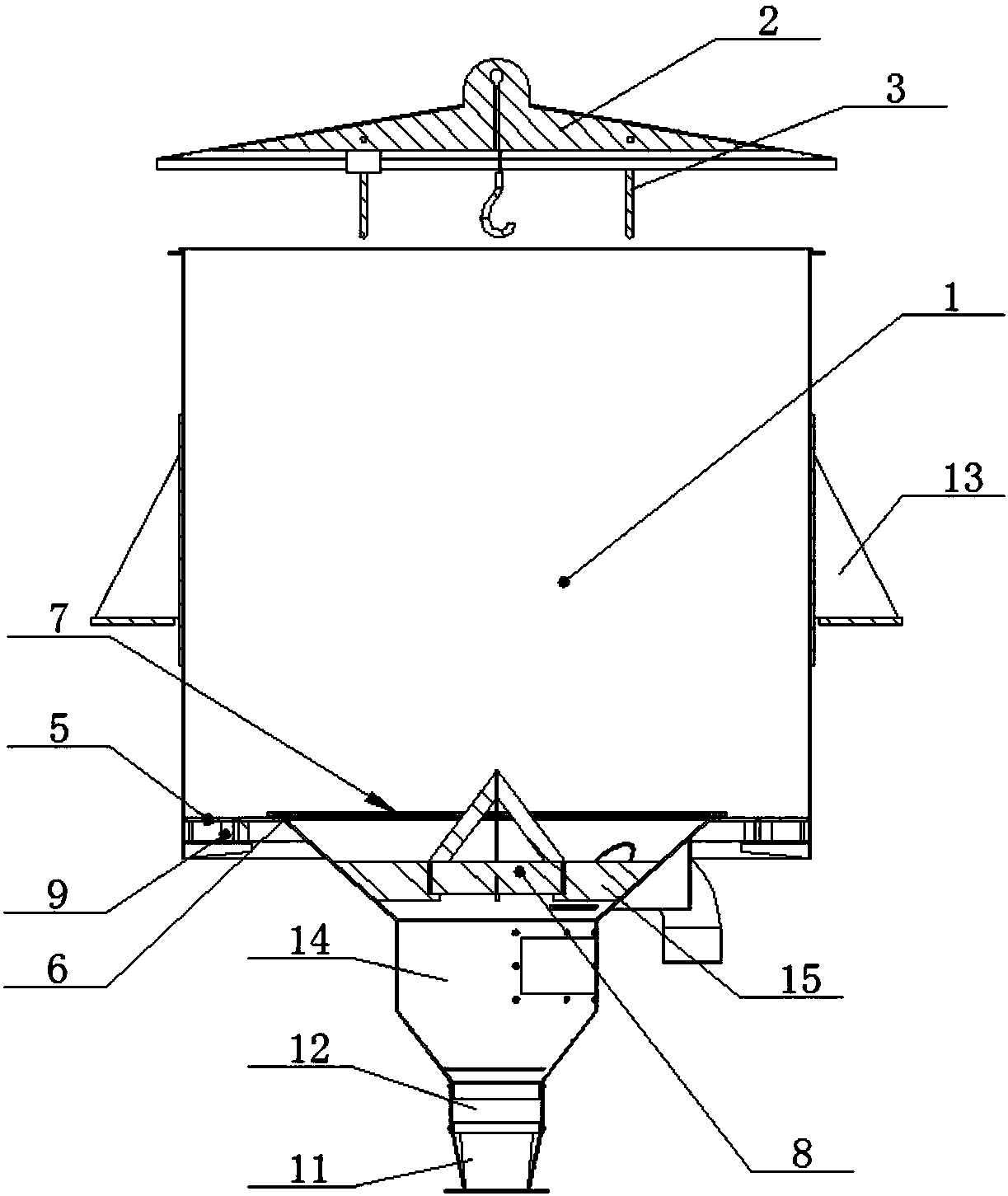

[0017] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a cylinder body 1, a top cover 2, a top cover hook 3, a large bag tray 5, a pallet compression flange 7, an unpacking bayonet 8, a lower hopper 11, The lower hopper soft connection 12, the lower storage space 14, the cylinder body 1 is a cylinder, the top of the cylinder body 1 is provided with a top cover 2, the center of the bottom of the top cover 2 is provided with a top cover hook 3, and the bottom of the cylinder body 1 is provided with There is a lower storage space 14, and the lower storage space 14 is connected to the lower hopper 11 through the lower hopper soft connection 12; the inner bottom of the cylinder 1 is provided with a large bag tray 5, and the top of the large bag tray 5 is provided with a pallet pressing method Lan 7, the bottom center of supporting plate compression flange 7 is provided with unpacking bayonet 8.

[0018] A top cover sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com