Copper busbar electric heating device and method of using the same

A heating device and busbar electricity technology, applied in auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of damage to insulating sleeves and low construction efficiency, achieve uniform and stable heating temperature, improve construction efficiency, reduce Effects of occupational health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

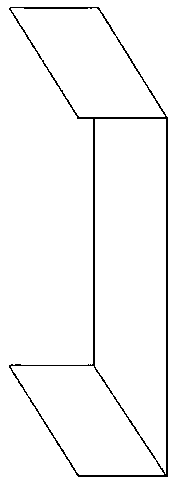

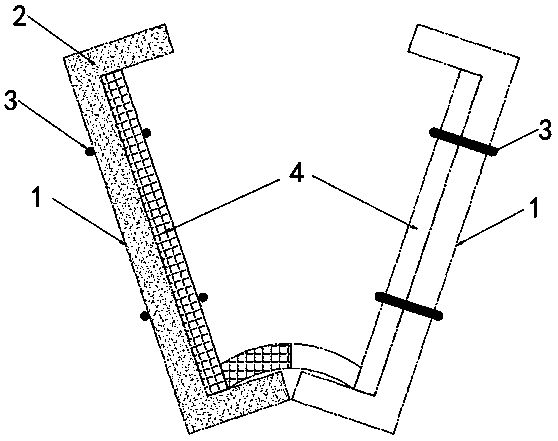

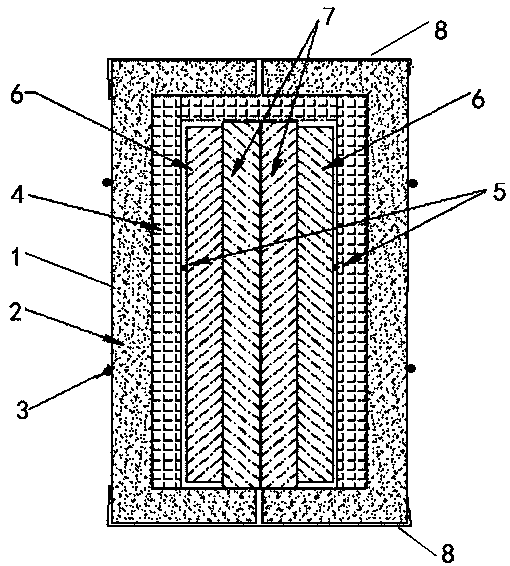

[0020] An electric heating device for copper busbars, comprising two clamping boxes 1 provided with concave cavities, thermal insulation cotton 2, electric heating sheet 4 and several clamping boxes for closely fitting the two clamping boxes 1 The thickness of the insulation cotton 2 is uniformly fixed in the cavity of the clamping box 1, and the electric heating sheet 4 is fixed on the outside of the insulation cotton 2 to heat the copper busbar.

[0021] In the above-mentioned copper busbar electric heating device, the thickness of the thermal insulation cotton 2 is 35-60mm.

[0022] For the electric heating device for the copper busbar, the clamping box 1 is a thin iron sheet with a thickness not greater than 1mm; At least two groups of binding iron wires 3 are wound and fixed in the cavity of the clamping box 1 .

[0023] The method for using the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com