Resourceful treatment system of coking distillation residues and treatment method thereof

A treatment system and resource recovery technology, applied in the field of harmless treatment and resource utilization of hazardous waste, can solve problems such as incomplete combustion of distillation residues, a large amount of pollutants, and environmental pollution, and achieve effective reuse and ash content Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

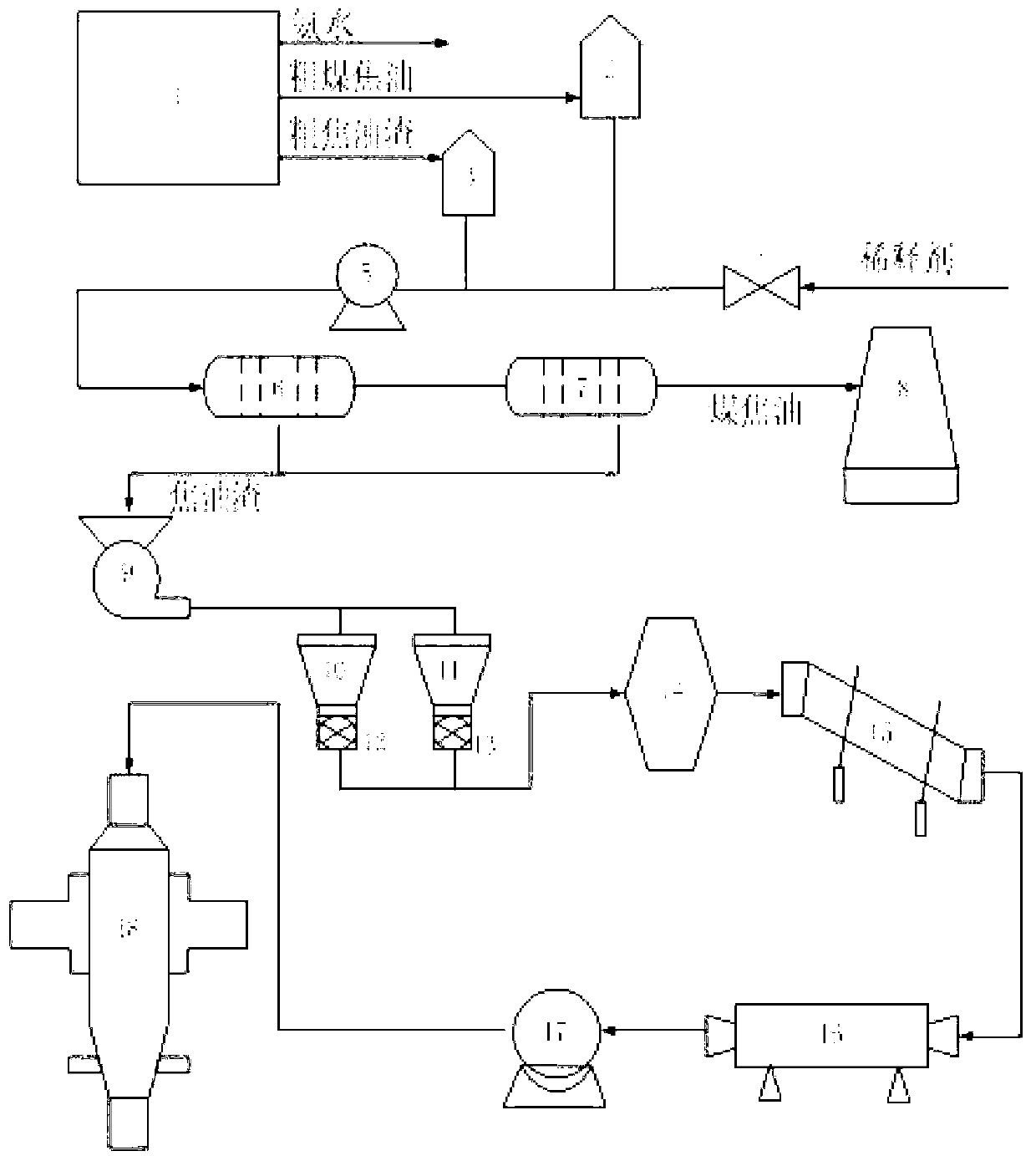

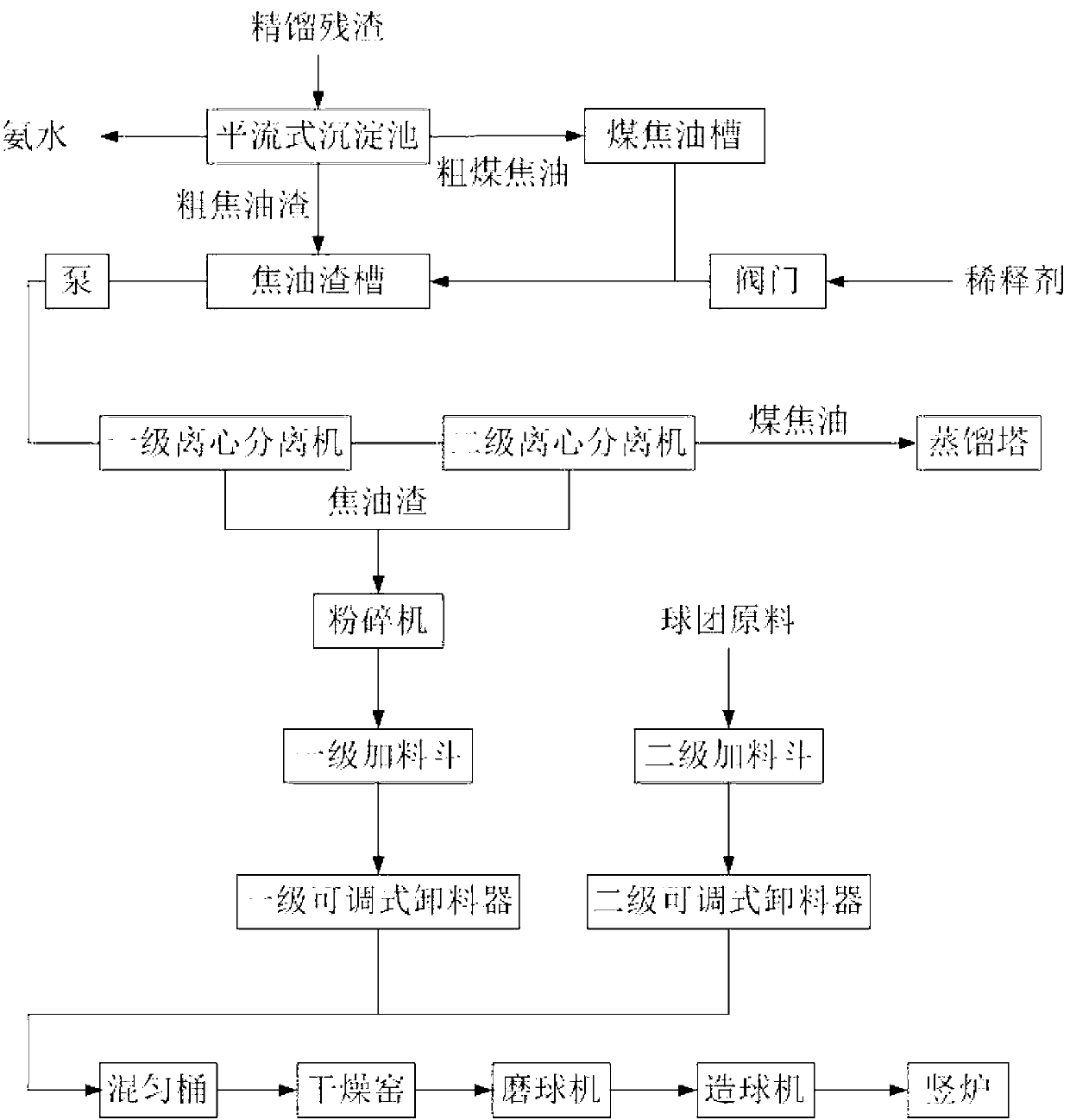

[0035] like figure 1As shown, a resource treatment system for coking and rectification residues, the system includes a flat-flow sedimentation tank 1, a coal tar tank 2, a tar residue tank 3, a series centrifugal separator, a distillation tower 8, a pulverizer 9, a hopper, Unloading hopper, mixing barrel 14, drying kiln 15, ball mill 16, pelletizing machine 17 and shaft furnace 18, the middle part of the advection type sedimentation tank 1 is connected with the coal tar tank 2, and the bottom part of the advection type sedimentation tank 1 is connected with the tar residue The tank 3 is connected, and the coal tar tank 2 and the bottom of the tar residue tank 3 are respectively provided with an outlet, and the outlet is connected with a pump 5, and the other end of the pump 5 is connected with a series centrifuge, and the middle part of the series centrifuge is connected with The distillation tower 8 is connected, the lower part of the series centrifuge is connected with the i...

Embodiment 2

[0044] A resource treatment system for coking and rectification residues, the system includes a flat-flow sedimentation tank 1, a coal tar tank 2, a tar residue tank 3, a centrifugal separator connected in series, a distillation tower 8, a pulverizer 9, a hopper, a hopper, Mixing bucket 14, drying kiln 15, ball mill 16, pelletizing machine 17 and shaft furnace 18, the middle part of the advection sedimentation tank 1 is connected with the coal tar tank 2, and the lower part of the advection sedimentation tank 1 is connected with the tar residue tank 3 , the bottom of the coal tar tank 2 and the tar residue tank 3 are respectively provided with an outlet, the outlet is connected to a pump 5, and the other end of the pump 5 is communicated with a series centrifuge, and the middle part of the series centrifuge is connected to a distillation tower 8 Connected, the lower part of the series centrifuge is connected to the inlet of the pulverizer 9, the outlet of the pulverizer 9 is co...

Embodiment 3

[0053] The resource treatment system for the coking and rectifying residue is basically the same as that of Examples 1 and 2, except that the inflow baffle is 0.25m higher than the height of the rectification residue in the pool, and the immersion depth of the inflow baffle is 0.5m. m, the baffle at the outflow is 0.2m higher than the rectification residue in the pool, and the immersion depth of the baffle at the outflow is 0.3m.

[0054] The resource treatment method of the coking and rectification residue in the system is basically the same as that in Examples 1 and 2, the difference is that before the step 3), 25% diluent heavy benzene is sent to the coal tar outlet through valve 4 control Dilute 75% crude coal tar. The particle size of the pulverized tar residue in the step 5) is 1.5 mm, and the mass ratio of the pulverized tar residue and the pellet raw material for pelletizing is: 2.5% of the tar residue and 97.5% of the pellet raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com