Coal tar deep processing technology based on four mixed fractions

A technology for deep processing and coal tar, applied in the field of new high-efficiency and low-consumption tar processing technology, coal tar deep processing technology based on four mixed fractions, to achieve the effect of low investment, low energy consumption, and reasonable design of process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

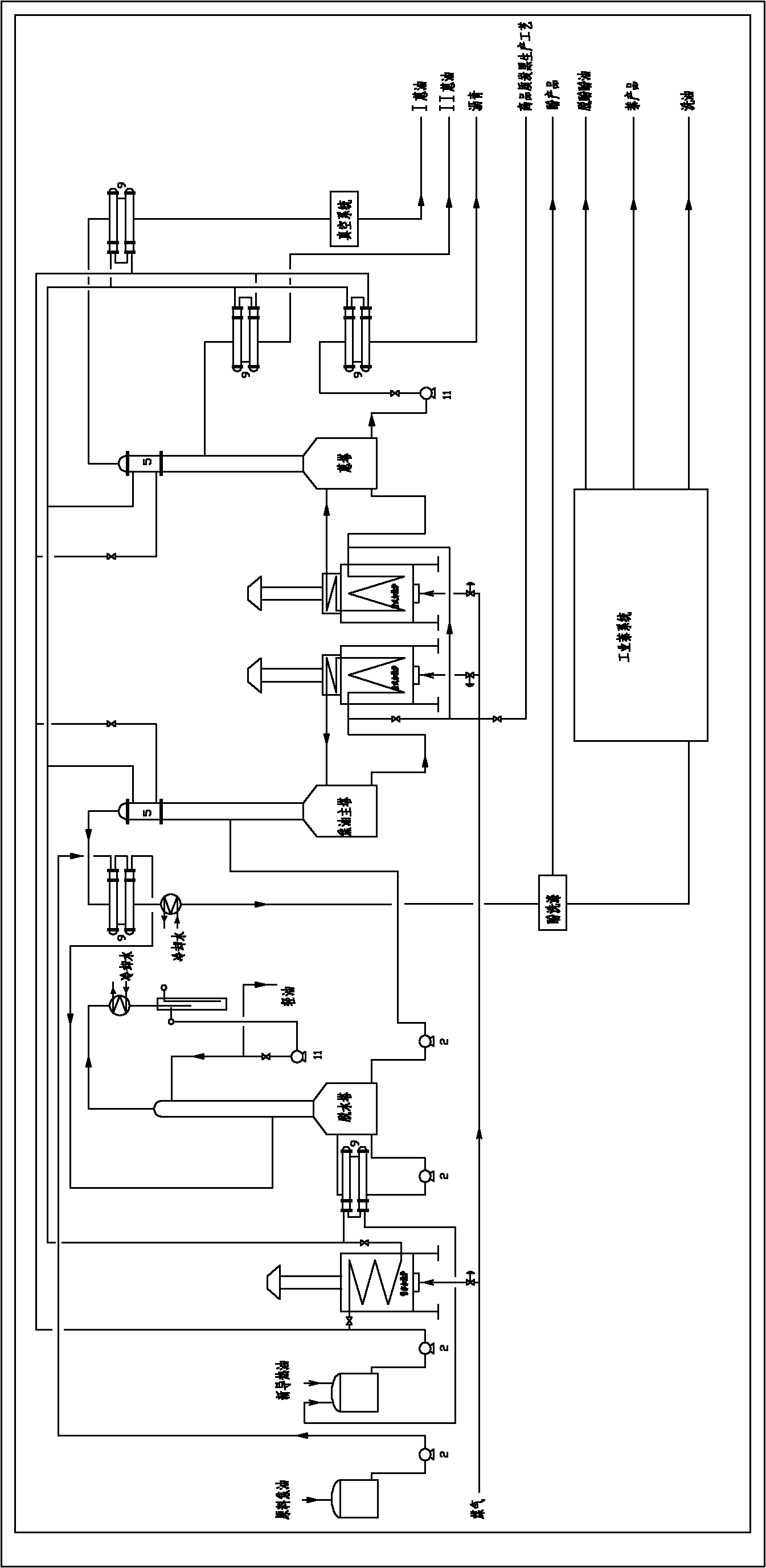

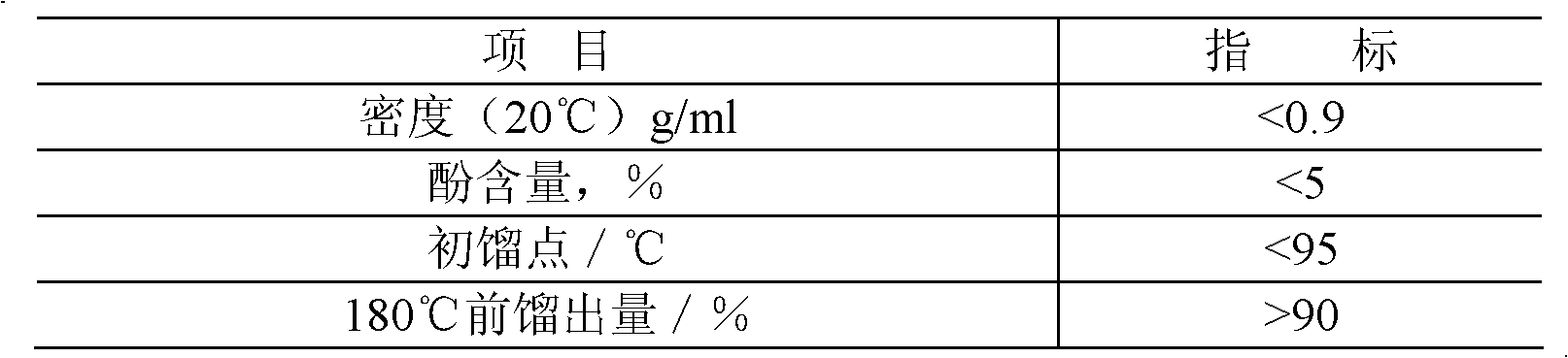

[0020] As shown in the accompanying drawings, in the coal tar deep processing technology based on the four-mixed fraction provided by the preferred embodiment of the present invention, the high-temperature coal tar produced by blast furnace coke production has properties shown in Table 1, and is heated to 120°C by a tar heat exchanger to enter Dehydration tower, water and part of light oil are separated from the top of the dehydration tower (the main property indicators are shown in Table 2), and the bottom of the tower is anhydrous tar. The dehydration tower is equipped with 12 high-efficiency trays to ensure distillation efficiency.

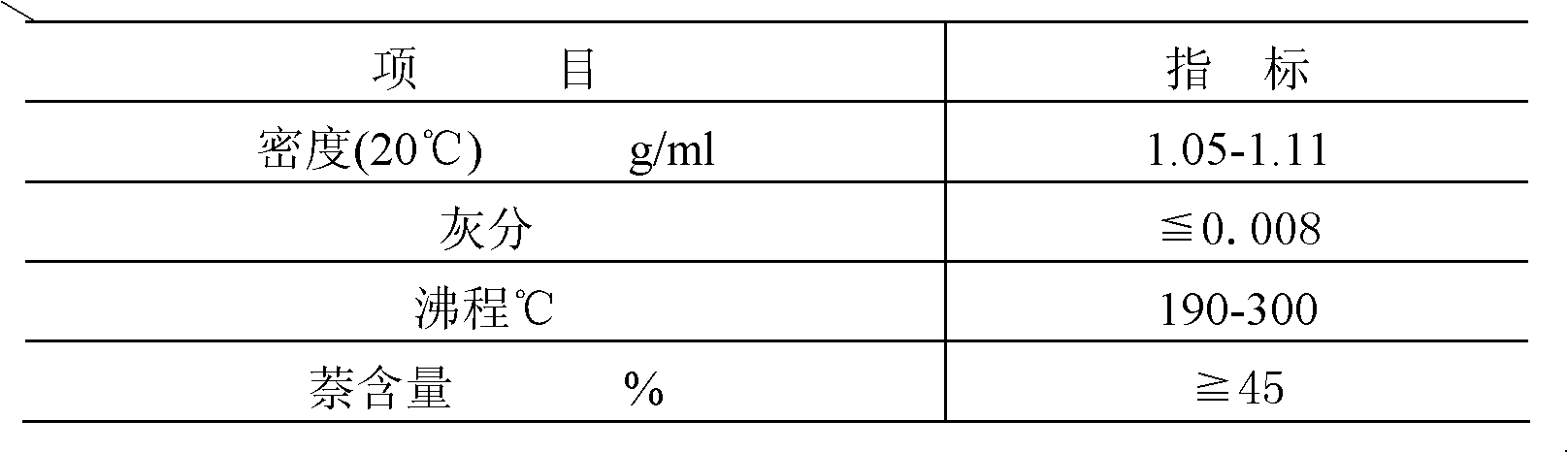

[0021] The dehydrated tar passes through a heat transfer oil heat exchanger and is heated to 270°C by a tubular heating furnace and enters the middle and lower part of the tar main tower. The bottom of the tower is heated by a tubular heating furnace for a heating cycle. The light phenol-naphthalene washing four mixed distillate is cut from the...

Embodiment 2

[0023] As shown in the accompanying drawings, in the coal tar deep processing technology based on four-mixed fractions provided by another preferred embodiment of the present invention, the high-temperature coal tar produced by blast furnace coke production has properties shown in Table 1 and is heated to 120 °C through a tar heat exchanger. ℃ enters the dehydration tower, and water and part of light oil are separated from the top of the dehydration tower (the main property indicators are shown in Table 2), and the bottom of the tower is anhydrous tar. The dehydration tower is equipped with 12 high-efficiency trays to ensure distillation efficiency.

[0024] The dehydrated tar passes through a heat transfer oil heat exchanger and is heated to 270°C by a tubular heating furnace and enters the middle and lower part of the tar main tower. The bottom of the tower is heated by a tubular heating furnace for a heating cycle. The light phenol-naphthalene washing four mixed distillate ...

Embodiment 3

[0027] As shown in the accompanying drawings, in the coal tar deep processing technology based on four-mixed fractions provided by another preferred embodiment of the present invention, the high-temperature coal tar produced by blast furnace coke production has properties shown in Table 1, and is heated to 120 °C through a tar heat exchanger. ℃ enters the dehydration tower, and water and part of light oil are separated from the top of the dehydration tower (the main property indicators are shown in Table 2), and the bottom of the tower is anhydrous tar. The dehydration tower is equipped with 12 high-efficiency trays to ensure distillation efficiency.

[0028] The dehydrated tar passes through a heat transfer oil heat exchanger and is heated to 270°C by a tubular heating furnace and enters the middle and lower part of the tar main tower. The bottom of the tower is heated by a tubular heating furnace for a heating cycle. The light phenol-naphthalene washing four mixed distillate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com