Oil extraction and slag removal method and system for vertical tar-ammonia water separating process

A technology for the separation of tar, ammonia, and tar residue, which is applied in the field of separation, and can solve the problems of small volume of mechanized scraping slag tank, inability to completely discharge the system, and affect the stable operation of the system, so as to achieve convenient tar extraction, strong on-site practicability, and tar recovery. a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a method and system for oil recovery and deslagging in a vertical tar ammonia water separation process.

[0019] The vertical tar and ammonia water separation process oil recovery and deslagging system according to an exemplary embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

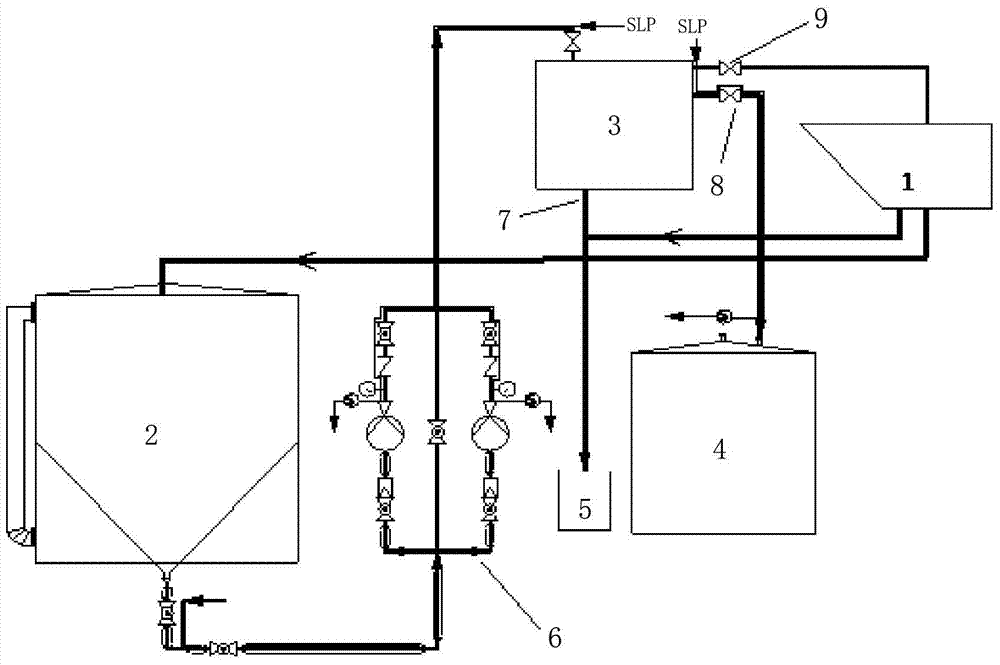

[0020] figure 1 is a schematic diagram showing a vertical tar ammonia water separation process oil recovery and deslagging system according to an exemplary embodiment of the present invention.

[0021] Such as figure 1 As shown, the vertical tar and ammonia water separation process oil recovery and deslagging system according to the present invention includes: a mechanized slag scraping tank 1, which separates the mixture of tar, ammonia water and tar residue from the coke oven for the first time; tar and ammonia water separation tank 2, which receives the initial The separated tar, ammonia water and small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com