Coal tar coupled rotational flow purification method and apparatus

A coal tar and micro-swirling technology, which is applied in tar processing, tar removal processing by water, tar processing by selective solvent extraction, etc., can solve the problems of cumbersome process, expensive equipment and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

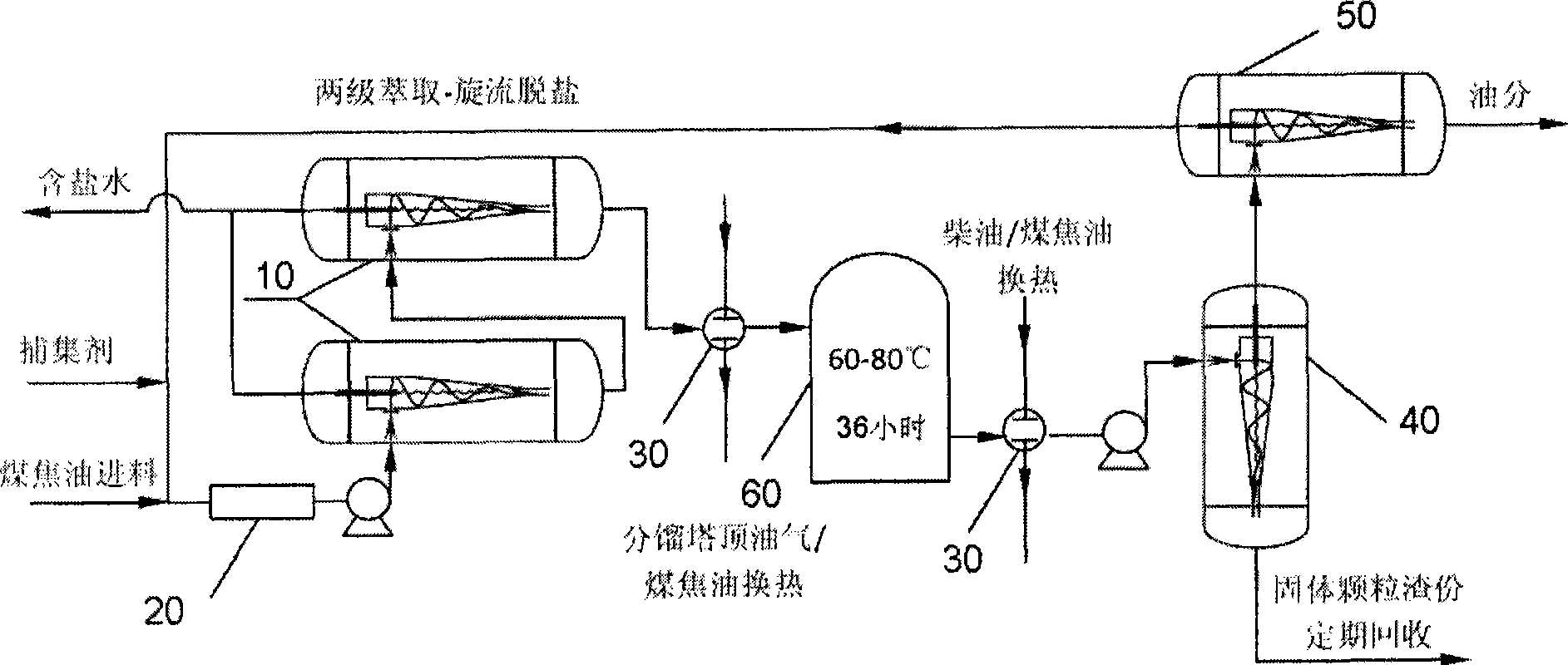

[0061] Example 1: Shaanxi Shenmu Fuyou Energy Technology Co., Ltd. 12×10 4 Ton / year comprehensive utilization of medium and low temperature coal tar Medium and low temperature coal tar refining unit in the project

[0062] Properties of coal tar (the design raw material is based on 3#):

[0063] The coal tar properties in this plant are shown in Table 1 below.

[0064] Table 1

[0065]

Embodiment approach

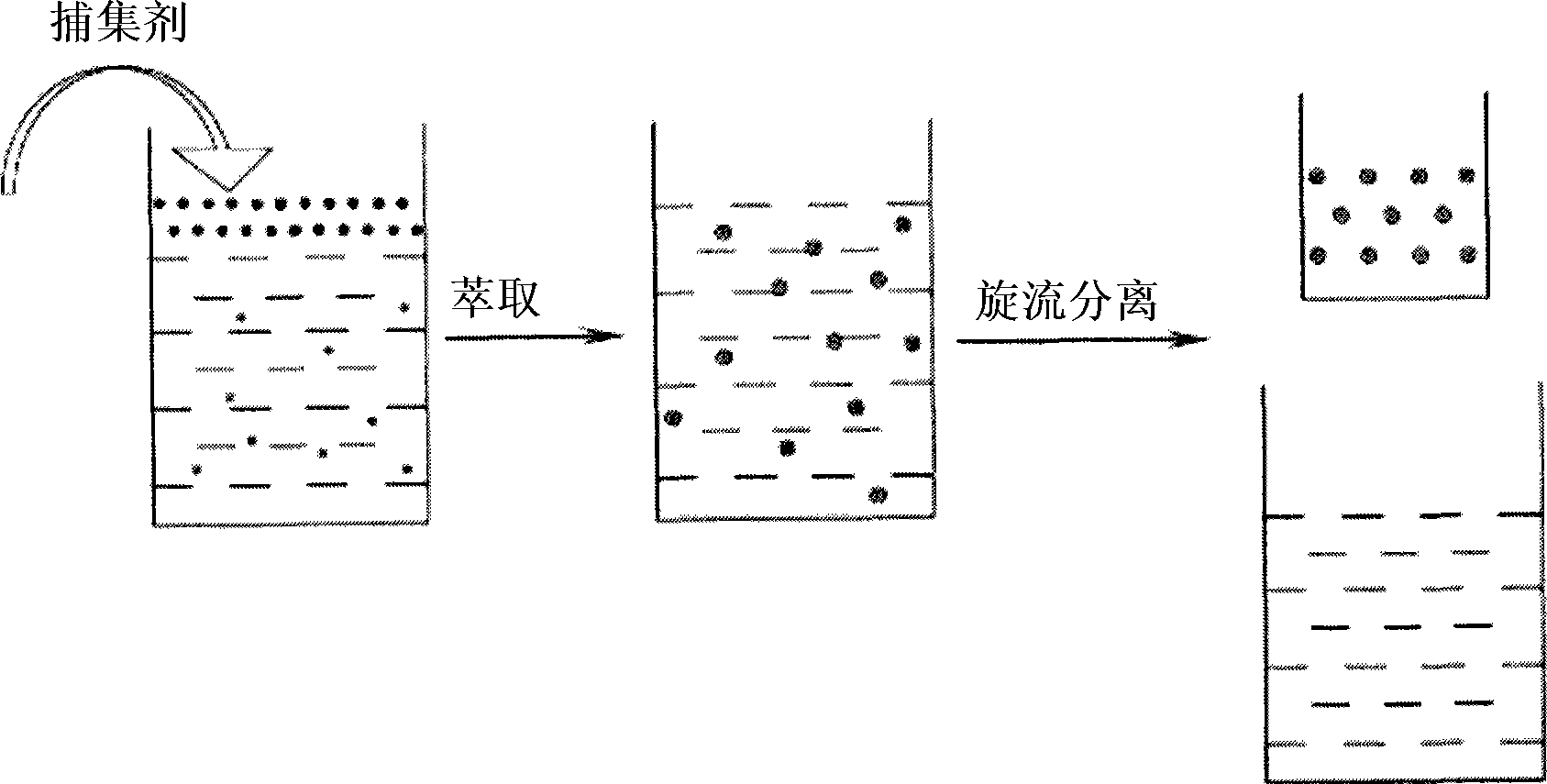

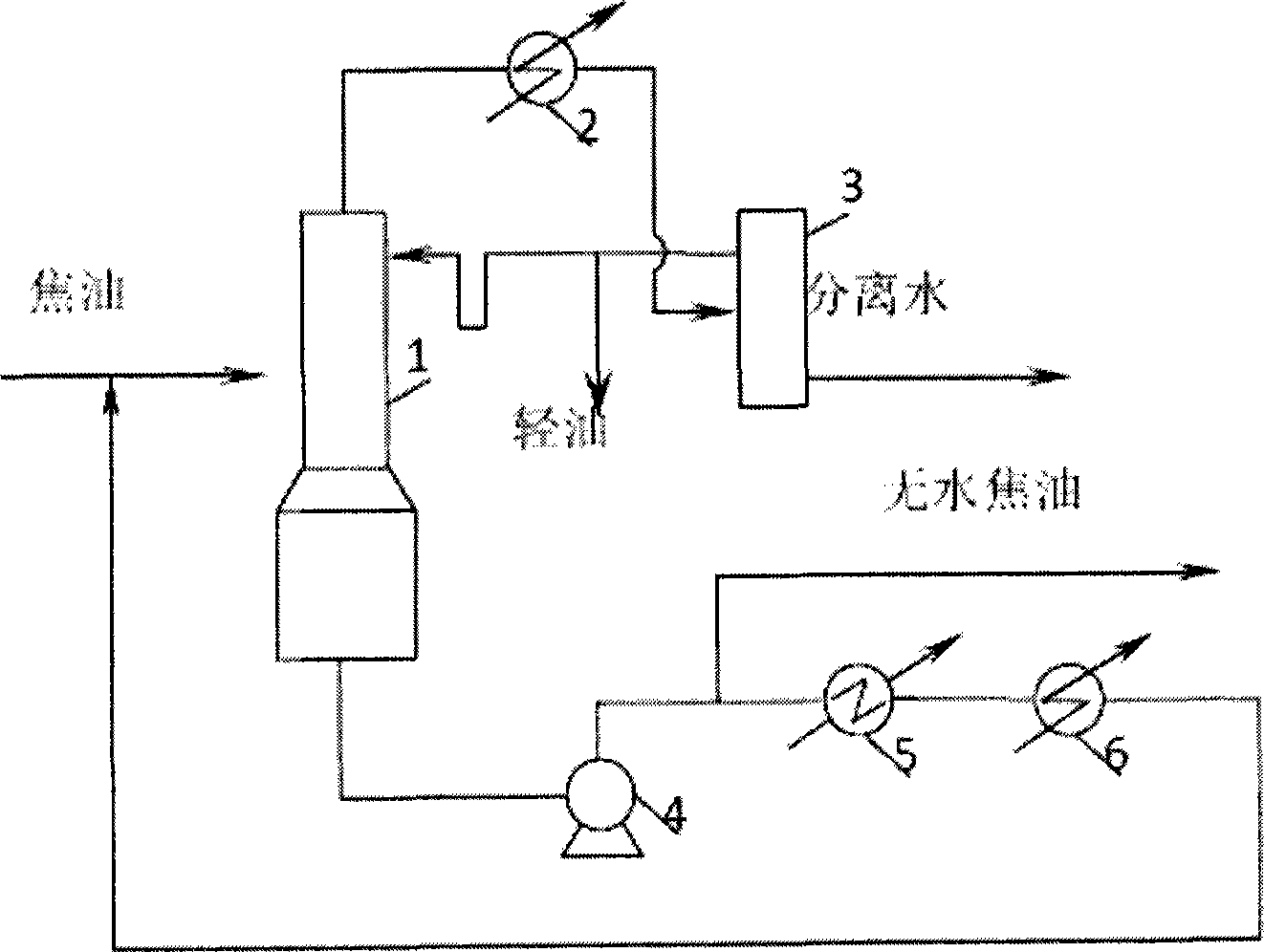

[0067] First, fresh water is injected into the coal tar feed, and the static mixer is fully mixed and extracted, so that the salt in the feed can be fully integrated into the water; the material is sent to the two-stage liquid-liquid cyclone separator through a pump for full separation, so that The salty sewage is fully removed, while the oil is heated to 60-80°C through the oil gas / coal tar heat exchange at the top of the fractionating tower, and dehydrated in the static tank. The dehydration efficiency can reduce the water content to 2-3%; rough dehydration The final coal tar is then heated to about 130°C through diesel / coal tar heat exchange, and the viscosity of the coal tar is appropriately reduced, and then it is passed into a solid-liquid cyclone separator to remove solid particles; the purified coal tar is then passed into a micro cyclone Fine separation is carried out in the separator to further remove the remaining trace moisture in the coal tar, so that the moisture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com