Method for treating coal chemical industry sewage

A treatment method and technology of coal chemical industry, applied in heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of strong biodegradability, favorable growth and reproduction, and low salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

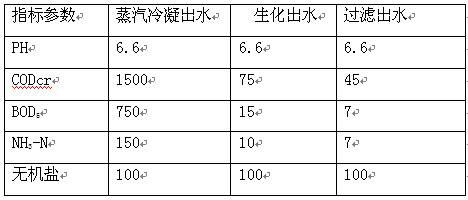

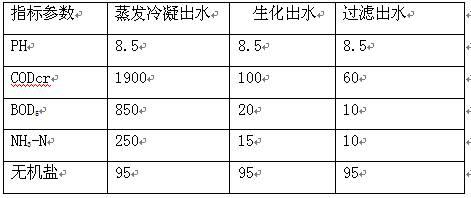

Embodiment 1

[0056] Send the sewage discharged from the bottom of the ammonia distillation tower into the evaporator, and evaporate it under the conditions of evaporator pressure 101KPa and temperature 100℃, control 65% of the sewage entering the evaporator as steam, and the remaining 35% as reflux concentration The liquid is returned to the circulating ammonia water system. During the process of circulating ammonia water to cool coking gas, the macromolecular substances brought in by the reflux concentrated liquid dissolve into coal tar, and then the coal tar and ammonia water settle and separate, and the coal tar is discharged for sale.

[0057] The 100°C steam evaporated from the evaporator is pressurized to 116KPa by the compressor, and the temperature reaches 104°C, and then used as a heat source, it is passed into the heating pipe of the evaporator, and the condensed water obtained after heat exchange is condensed. The biochemically treated condensed sewage required by the present inv...

Embodiment 2

[0069] Send the sewage discharged from the bottom of the ammonia distillation tower into the evaporator, and evaporate it under the condition of evaporator pressure 101KPa and temperature 100°C, control 75% of the sewage entering the evaporator as steam, and the remaining 25% as reflux concentration The liquid is returned to the circulating ammonia water system. During the process of circulating ammonia water to cool coking gas, the macromolecular substances brought in by the reflux concentrated liquid dissolve into coal tar, and then the coal tar and ammonia water settle and separate, and the coal tar is discharged for sale.

[0070] The 100°C steam steamed from the evaporator is pressurized to 116KPa by the compressor to make the temperature reach 104°C, and then used as a heat source, and then passed into the heating pipe of the evaporator, and the condensed water obtained after heat exchange is condensed. The condensed sewage required for biochemical treatment is sent to th...

Embodiment 3

[0082] Send the sewage discharged from the bottom of the ammonia distillation tower into the evaporator, and evaporate it under the condition of evaporator pressure 101KPa and temperature 100°C, control 70% of the sewage entering the evaporator as steam, and the remaining 30% as reflux concentration The liquid is returned to the circulating ammonia water system. During the process of circulating ammonia water to cool coking gas, the macromolecular substances brought in by the reflux concentrated liquid dissolve into coal tar, and then the coal tar and ammonia water settle and separate, and the coal tar is discharged for sale.

[0083]The 100°C steam steamed from the evaporator is pressurized to 116KPa by the compressor to make the temperature reach 104°C, and then used as a heat source, it is passed into the heating pipe of the evaporator, and the condensed water obtained after heat exchange is condensed water. The condensed sewage required for biochemical treatment is sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com