Demulsification, neutralization and dehydration method of acidic emulsified tar

A treatment method and technology for tar, applied in the field of coal chemical industry, can solve the problems of increased safety risks, equipment corrosion, excessive pressure of the second-stage pump, etc., and achieve the effects of reducing economic losses, avoiding equipment corrosion, and avoiding safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

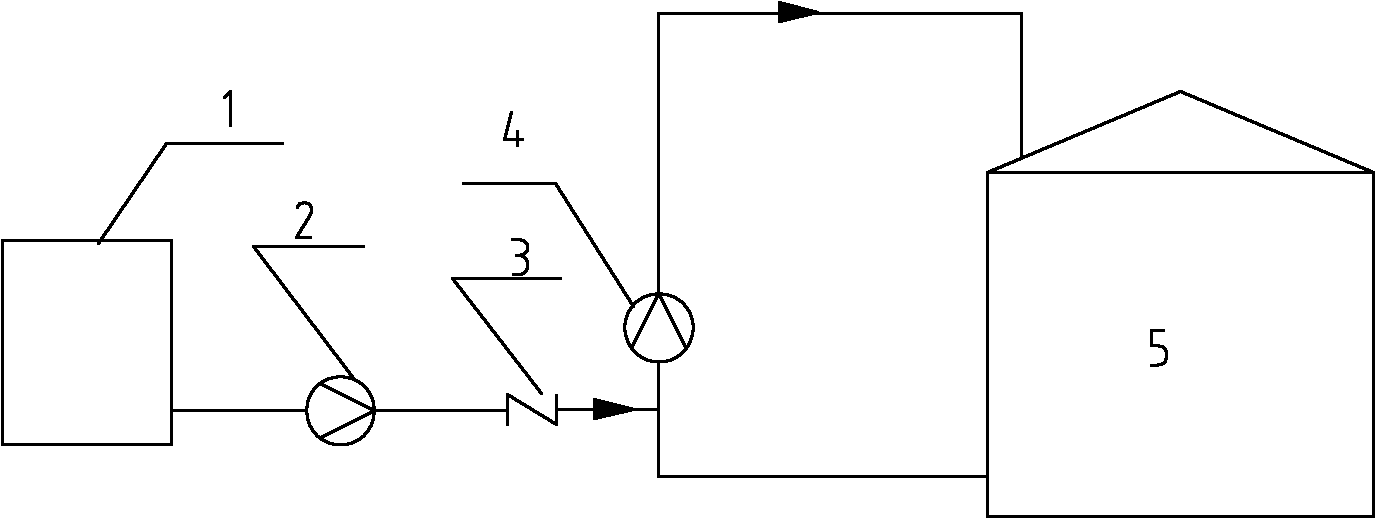

[0032] (1) Chemical demulsification and dehydration: such as figure 1 As shown, the equipment for chemical demulsification includes a tar tank 5 and a tar circulation pump 4, and a loop is formed between the tar circulation pump and the tar tank; the demulsifier tank 1, the metering pump 2 and the check valve 3 are connected to the tar circulation pump 4 inlet in turn .

[0033] 1500 parts of acid emulsified tar with a water content of 23.9% in the tar tank 5 was heated to 70°C. Dilute the demulsifier A and prepare a 30 wt% aqueous solution in the demulsifier tank 1. The tar is circulated, and the circulation pump 4 has a flow rate of 100 parts / h. Open metering pump 2 and check valve 3, and add demulsifier into the circulation pipeline. The flow rate of the metering pump 2 is 0.1 part / h, and the addition time is 25 hours. After all the demulsifiers are added, continue to beat the cycle for 3 hours. The addition ratio of the demulsifier is 500ppm (parts by weight).

[003...

Embodiment 2

[0041] Equipment is with embodiment 1.

[0042](1) Heat 1500 parts of acid emulsified tar with a water content of 23.9% in the tar tank 5 to 80°C. Dilute the demulsifier B and prepare a 25 wt% aqueous solution in the demulsifier tank 1. The tar is circulated, and the circulation pump 4 has a flow rate of 150 parts / h. Open the metering pump 2 and check valve 3 of the demulsifier, and add the demulsifier into the circulation pipeline. The flow rate of metering pump 2 is 0.2 parts / h, and the addition time is 15 hours. After adding all the demulsifiers, continue to beat the cycle for 10h. The addition ratio of the demulsifier is 500ppm. The tar was heated to 94°C. After the cycle is over, the rest time is 30h. When the tar is transported, the moisture content of the tar is analyzed at 3% to 4% in different time periods.

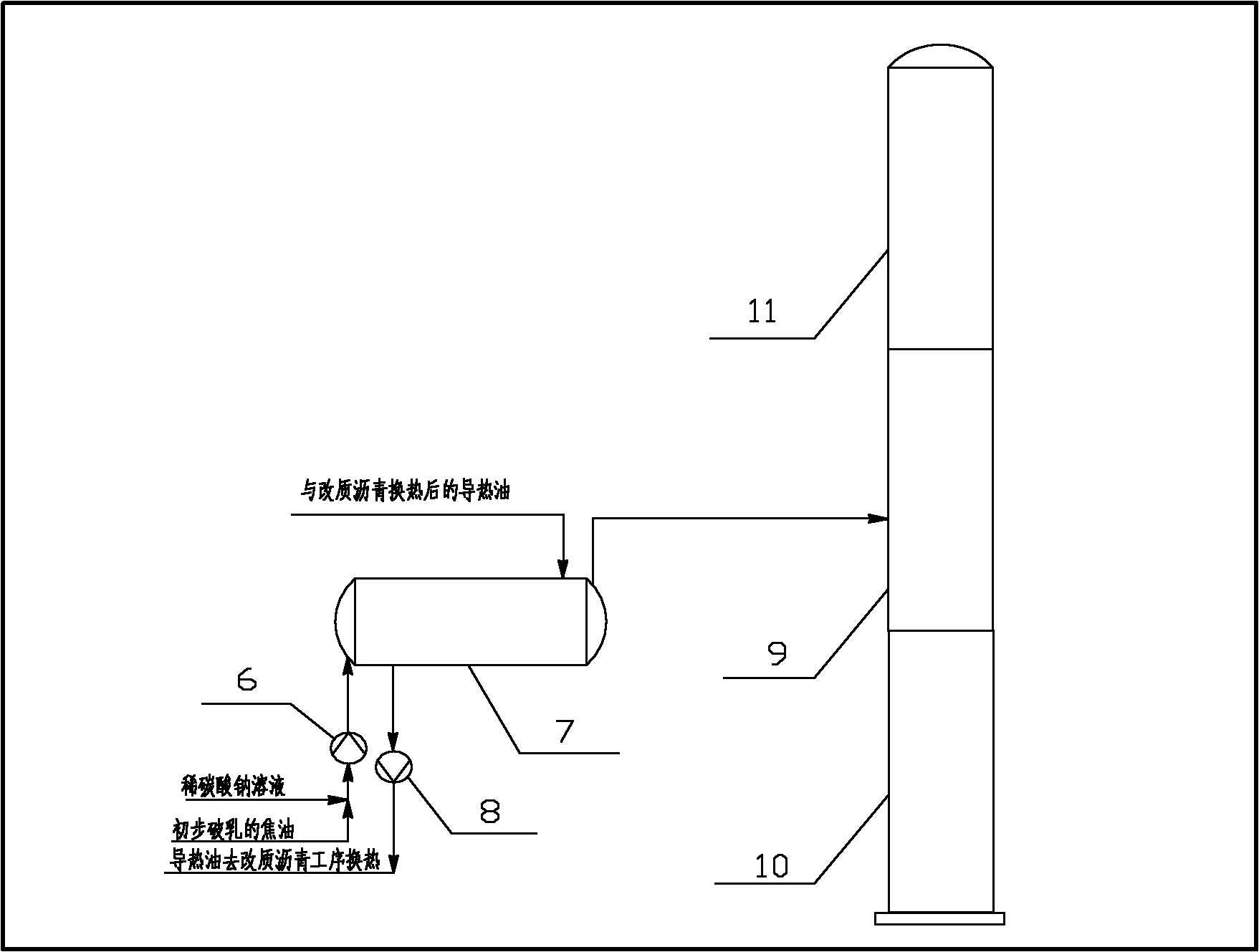

[0043] (2) The tar after preliminary dehydration is pressurized 0.3MPa by the first-stage pump 6, and the flow rate is 15 parts / h, and 15% Na is added at ...

Embodiment 3

[0045] Equipment is with embodiment 1.

[0046] (1) Heat 1500 parts of acid emulsified tar with a water content of 15% in the tar tank 5 to 90°C. Dilute the demulsifier B and prepare a 20 wt% aqueous solution in the demulsifier tank 1. The tar is circulated, and the circulation pump 4 has a flow rate of 200 parts / h. Open the metering pump 2 and check valve 3 of the demulsifier, and add the demulsifier into the circulation pipeline. The flow rate of the metering pump 2 is 0.3 parts / h, and the addition time is 10 hours. After adding all the demulsifiers, continue to beat the cycle for 15 hours. The addition ratio of the demulsifier is 400ppm. The tar was heated to 96°C. After the cycle, the rest time is 36h. When the tar is transported, the tar moisture is analyzed at 1% to 2% in different time periods.

[0047] (2) The tar after preliminary dehydration is pressurized 0.4MPa by the first-stage pump 6, and the flow rate is 20 parts / h, and 15% Na is added at the inlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com